Description

DS3800HPRB1C1B: Product Overview

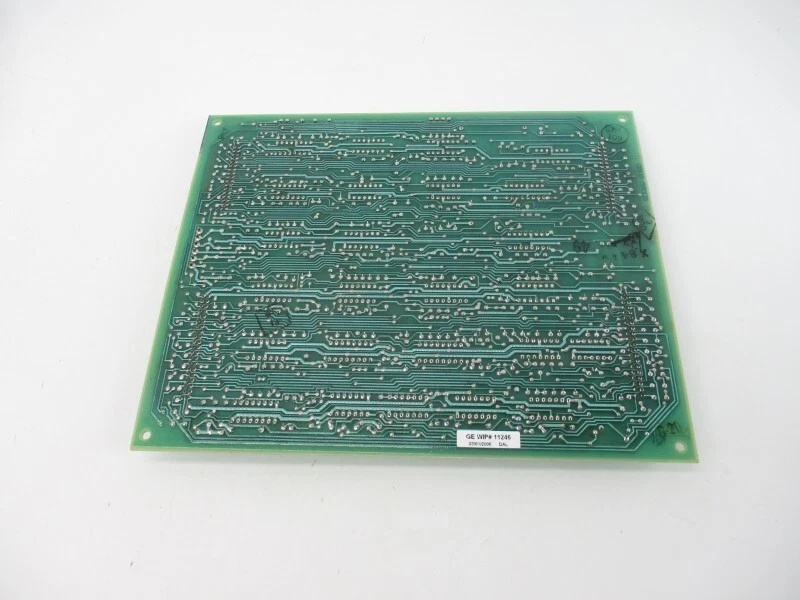

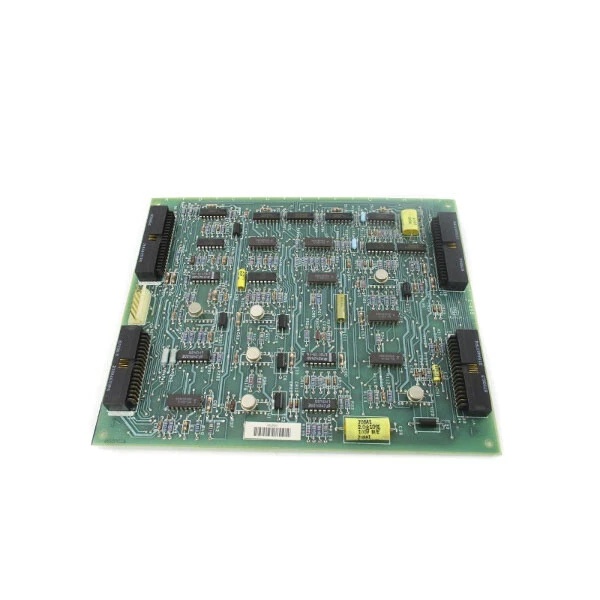

This board occupies a 6BA Euro-card slot in GE Mark IV turbine and EX2000 exciter control racks, serving as a high-power relay interface between the low-voltage CPU and field contactors. It receives 5 V CMOS commands from the processor, buffers them through opto-isolated driver stages, and energizes relay coils or contactors at 24 Vdc or 125 Vdc levels up to 5 A. The “HPRB” designation indicates high-power relay buffer functionality, while the C1B revision includes enhanced surge protection and contact arc suppression for inductive loads.

This board occupies a 6BA Euro-card slot in GE Mark IV turbine and EX2000 exciter control racks, serving as a high-power relay interface between the low-voltage CPU and field contactors. It receives 5 V CMOS commands from the processor, buffers them through opto-isolated driver stages, and energizes relay coils or contactors at 24 Vdc or 125 Vdc levels up to 5 A. The “HPRB” designation indicates high-power relay buffer functionality, while the C1B revision includes enhanced surge protection and contact arc suppression for inductive loads.

The epoxy-sealed construction makes this a line-replaceable module—internal faults require complete card swap rather than field repair. The module hot-swaps when the rack is powered down, and its low profile allows adjacent-slot population without additional cooling. As part of the DS3800 family, it benefits from the Mark IV platform’s deterministic 2 ms control interval and extensive installed base in power generation applications.

GE DS3800NGRC1F1F

DS3800HPRB1C1B: Technical Specifications

-

Model Number: DS3800HPRB1C1B

-

Manufacturer: General Electric (GE Fanuc)

-

Product Type: High-Power Relay Buffer / Relay Driver Board

-

Series: DS3800, Mark IV Speedtronic

-

Form Factor: 6BA Euro-card (≈ 233 × 160 mm)

-

Back-Plane Connector: Dual 40-pin header (J1/J2)

-

Output Type: Form-C relay contacts, 5 A @ 250 Vac / 30 Vdc

-

Coil Drive: 24 Vdc or 125 Vdc (jumper-selectable per channel)

-

Isolation: 1500 Vdc field-to-logic; opto-coupled driver stages

-

Response Time: <10 ms pick / <5 ms drop (typical)

-

Arc Suppression: Integrated RC snubbers and varistors (C1B enhancement)

-

Power Demand: +5 V @ 0.4 A, +24 V @ 2 A from rack 2PL bus

-

Operating Temperature: 0 – 60 °C

-

Weight: ≈ 0.35 kg

-

Construction: Epoxy-sealed copper traces—non-repairable

GE DS3800NGRC1F1F

Core Features & Customer Value

High-Current Relay Drive: The 5 A contact rating eliminates external interposing relays for most turbine auxiliary loads. For panel designers, this reduces component count, wiring complexity, and failure points while saving 30-40% of the space required for traditional relay logic.

Enhanced Arc Suppression: The C1B revision includes integrated RC networks and metal-oxide varistors across each contact. For maintenance teams, this extends relay life 3-5x in inductive load applications (contactor coils, brake solenoids) by quenching the arc energy that otherwise erodes contact surfaces.

Epoxy-Sealed Construction: All internal copper is encapsulated in high-temperature epoxy. In coastal or industrial environments with conductive dust and high humidity, this prevents trace-to-trace shorting that would cause random “RELAY FAIL” alarms or, worse, spurious contact closures after ten-plus years. The trade-off is non-repairability—internal faults require whole-card exchange—but this is offset by reduced troubleshooting time and single-spare stocking rather than maintaining a repair bench.

Typical Applications

In combined-cycle power plants, this board installs in the Mark IV turbine control core where it drives the main fuel-trip relay, lube-oil pump contactor, and cooling-fan starter. The 125 Vdc option supports direct interface with station battery systems without intermediate relays, critical for emergency trip circuits where speed is paramount.

On utility-scale EX2000 static exciters, the same card energizes the field-discharge contactor and exciter breaker trip coil. The integrated arc suppression is essential here—field inductance can generate 500+ V back-EMF that destroys unprotected contacts in milliseconds.

Mechanical-drive gas compressors frequently use this part number for the inlet-guide-vane hydraulic pump contactor and the anti-surge valve solenoid. The 5 A rating handles inrush currents that would weld smaller relay contacts, while the fast drop-out time (<5 ms) ensures rapid valve closure during surge events.