Description

DS3800HMPF1F1F: Product Overview

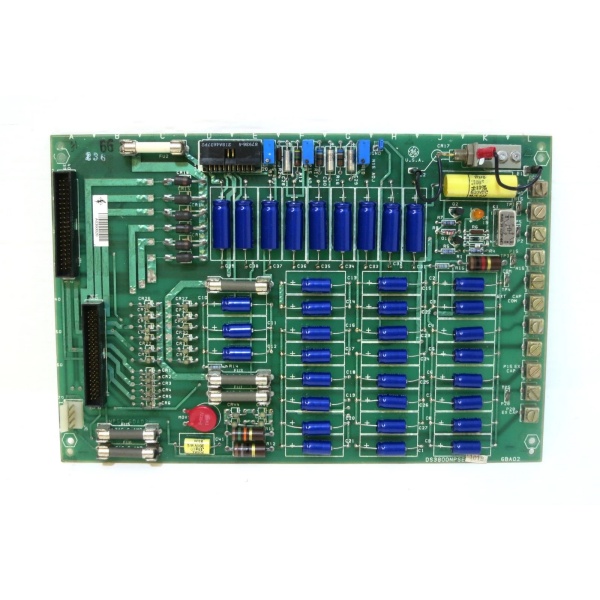

The DS3800HMPF1F1F is the central microprocessor board for GE Speedtronic Mark IV gas- and steam-turbine control racks. Occupying one 6BA03 slot, it hosts the primary control algorithm, I/O scanner, and TMR voter that govern speed PID, temperature limiting, fuel sequencing, and protective tripping. The card is hardware-identical across all three legs of the TMR string, ensuring bit-for-bit congruent outputs that are voted every 5 ms.

Physical implementation includes 48 integrated circuits (CPU, latches, parity generators), 37 gold-pinned jumpers for memory maps, scan rates, and I/O enables, and dual-edge VME backplane connectors. Front-edge LEDs (red/green) give at-a-glance health: solid green = leg congruent, blinking red = voter disagreement, solid red = watchdog timeout.

Environmental qualification meets IEEE 344 Class 1 (seismic) and –40 °C to +85 °C operation, permitting installation directly on the turbine deck with no extra HVAC. MTBF is >300 000 h at 55 °C, giving >25-year service life in baseload duty.

DS3800NPSE1C1B

DS3800HMPF1F1F: Technical Specifications

-

Model Number: DS3800HMPF1F1F

-

Manufacturer: General Electric (GE Energy)

-

Product Type: Central Processing Unit (CPU) Board

-

Processor: 16-bit control-oriented CPU with parity-checked buses

-

Memory: 64 kB direct map (expandable to 256 kB via daughterboard)

-

Scan Rate: 5 ms (configurable 2–10 ms via jumper)

-

I/O Capacity: 4096 DI/DO or 1024 AI/AO points (voted)

-

TMR Voting: Bit-wise majority voter, fail-fast on mis-compare

-

Backplane: Dual VME, 96-pin, gold-plated

-

Jumpers: 37 position, gold-plated, silk-screen legend

-

Power: +5 V DC @ 3 A, +12 V DC @ 0.5 A (from rack PSU)

-

Isolation: 500 V DC board-to-ground, 1500 V channel-to-channel

-

Temp Range: -40 °C to +85 °C operational, -55 °C to +125 °C storage

-

Vibration: 15 g continuous, 30 g shock (IEEE 344)

-

Certifications: SIL2 (IEC 61508), API 670, CE industrial emissions

Core Features & Customer Value

Triple-Modular Redundancy Without Single Point of Failure

Every instruction is executed identically on three HMPF boards; two-out-of-three voter output guarantees continued operation after any single CPU fault. Mean-time-to-repair (MTTR) is <10 min because the faulted leg is auto-disabled and the spare board can be inserted hot—no outage, no load shed.

Every instruction is executed identically on three HMPF boards; two-out-of-three voter output guarantees continued operation after any single CPU fault. Mean-time-to-repair (MTTR) is <10 min because the faulted leg is auto-disabled and the spare board can be inserted hot—no outage, no load shed.

Deterministic 5 ms Scan for Critical Protection

Overspeed, overtemperature, and loss-of-flame algorithms execute within one 5 ms scan, meeting API 670 response limits. Jitter is <50 µs thanks to crystal-based timing; this determinism is mandatory for grid-code frequency-response compliance.

Overspeed, overtemperature, and loss-of-flame algorithms execute within one 5 ms scan, meeting API 670 response limits. Jitter is <50 µs thanks to crystal-based timing; this determinism is mandatory for grid-code frequency-response compliance.

Field-Configurable Without Software Downloads

All mission-critical parameters (scan rate, I/O maps, voter masks) are jumper-selectable—no EEPROM flashing, no laptop on the turbine deck. During forced outages, technicians can re-purpose a spare board in <2 min using only a screwdriver and the silk-screen legend, minimising risk of incorrect configuration.

All mission-critical parameters (scan rate, I/O maps, voter masks) are jumper-selectable—no EEPROM flashing, no laptop on the turbine deck. During forced outages, technicians can re-purpose a spare board in <2 min using only a screwdriver and the silk-screen legend, minimising risk of incorrect configuration.

Seismic & Harsh-Environment Qualified

IEEE 344 Class 1 qualification allows installation on offshore platforms, earthquake zones, and desert sites with >40 °C ambient. Conformal coat and gold-plated edge fingers inhibit corrosion in salt-laden or high-dust environments, ensuring 25-year service life in baseload duty.

IEEE 344 Class 1 qualification allows installation on offshore platforms, earthquake zones, and desert sites with >40 °C ambient. Conformal coat and gold-plated edge fingers inhibit corrosion in salt-laden or high-dust environments, ensuring 25-year service life in baseload duty.

DS3800NPSE1C1B

Typical Applications

Gas Turbine Speed & Acceleration Control

Primary CPU for Frame 7/9 heavy-duty units: speed PID, acceleration schedule, fuel staging, and grid synchronizing. Triple redundancy ensures 99.97 % start reliability and <0.25 % forced-outage rate on combined-cycle fleets.

Primary CPU for Frame 7/9 heavy-duty units: speed PID, acceleration schedule, fuel staging, and grid synchronizing. Triple redundancy ensures 99.97 % start reliability and <0.25 % forced-outage rate on combined-cycle fleets.

Steam Turbine Load & Frequency Control

Load control, valve positioning, and frequency-response algorithms execute every 5 ms, maintaining grid stability during load rejection or island-mode operation. Deterministic voter guarantees seamless island-mode transition <100 ms after breaker open.

Load control, valve positioning, and frequency-response algorithms execute every 5 ms, maintaining grid stability during load rejection or island-mode operation. Deterministic voter guarantees seamless island-mode transition <100 ms after breaker open.

Black-Start & Emergency Diesel Interface

Acts as master timing reference for excitation, synchronizing, and load-sharing when grid is lost. Deterministic voter ensures phase-angle matching <0.5°, mandatory for NERC PRC-024-2 ride-through.

Acts as master timing reference for excitation, synchronizing, and load-sharing when grid is lost. Deterministic voter ensures phase-angle matching <0.5°, mandatory for NERC PRC-024-2 ride-through.