Description

DS3800HFPG1E1E: Product Overview

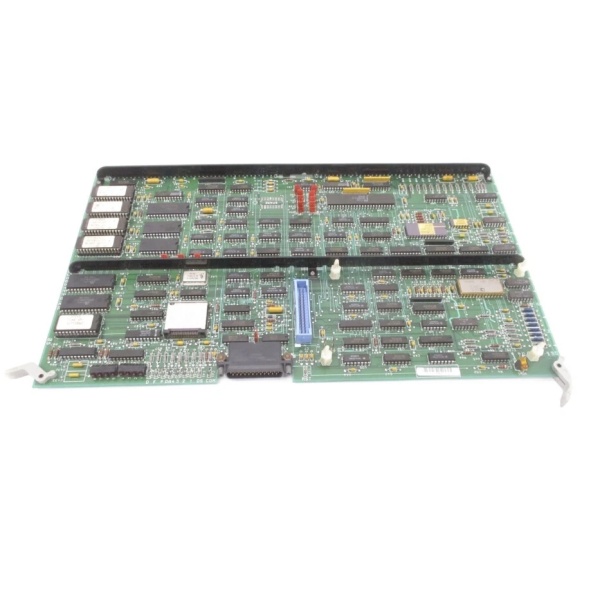

The board functions as an intelligent drive control interface within GE’s Speedtronic Mark IV turbine control architecture. Positioned within the control rack assembly, this module provides the processing intelligence necessary to manage auxiliary drive systems—such as variable frequency drives, servo amplifiers, and motor control centers—while maintaining deterministic communication with the central control processors. In the Mark IV’s triple modular redundant (TMR) system, this board operates within each independent control channel, executing drive control algorithms stored in non-volatile memory.

As a microprocessor-based control board, the unit manages the complex logic sequences required for drive startup, speed regulation, torque limiting, and protective shutdowns. The onboard microprocessor executes firmware instructions stored in multiple EPROM modules, enabling sophisticated control strategies including ramp acceleration profiles, load sharing algorithms, and fault ride-through capabilities. The transistor-transistor logic (TTL) devices provide robust interfacing between the microprocessor bus and external circuitry, ensuring signal integrity when communicating with other Mark IV modules and field equipment.

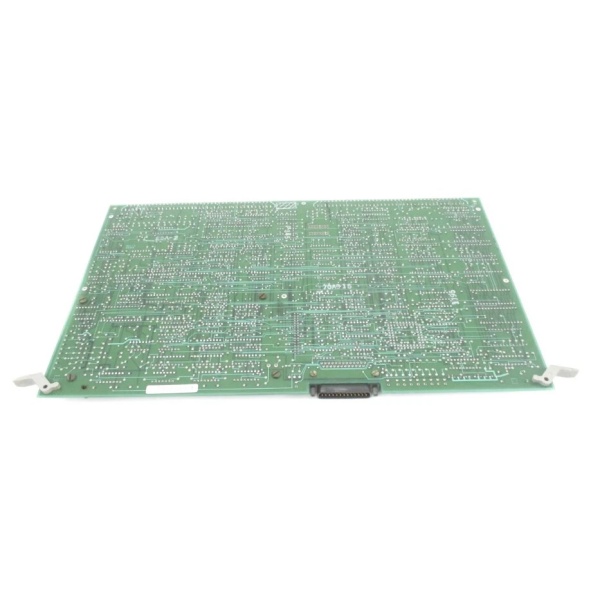

The board features a versatile connectivity architecture including a 34-pin connector accessible from the front panel and a 40-pin connector on the board surface. These interfaces support parallel communication with external drives, discrete I/O for drive status monitoring, and analog setpoint signals. The modular backplane connector ensures reliable integration with the Mark IV rack while retention levers prevent vibration-induced disconnections in industrial environments.

This board belongs to the DS3800 series of the Mark IV platform, designed for heavy-duty gas turbines (Frame 3, 5, 6, 7, 9) and LM aeroderivative units. The platform’s distributed control philosophy allows drive control functions to execute locally on this board while maintaining coordination with the turbine’s overall control strategy through high-speed backplane communication.

GE DS3800HFPG1E1E

DS3800HFPG1E1E: Technical Specifications

-

Model Number: DS3800HFPG1E1E

-

Manufacturer: General Electric

-

Product Type: Drive Control Board

-

Series: GE Speedtronic Mark IV

-

Processing Core: Dedicated microprocessor for drive control algorithms

-

Memory Architecture: Multiple EPROM modules for firmware and control parameter storage

-

Logic Interface: Transistor-Transistor Logic (TTL) devices for integrated circuit interfacing

-

Front Panel Interface: 1 x 34-pin connector (accessible from front)

-

Surface Connector: 1 x 40-pin connector (board-mounted)

-

Backplane Connection: High-density modular connector with locking retention levers

-

Firmware Storage: Erasable Programmable Read-Only Memory (EPROM) chips in socketed configuration

-

Test Access: Multiple test points for signal monitoring and diagnostic verification

-

Operating Temperature: -40°C to +70°C (industrial grade)

-

Humidity: 5% to 95% non-condensing

-

Mounting: Standard Mark IV rack slot with extraction handles

-

Power Supply: Derived from Mark IV rack backplane (typically 5VDC logic, ±15VDC analog)

-

Physical Construction: Multi-layer PCB with socketed memory devices for field replacement

Part 4: Core Features & Customer Value

Intelligent Drive Control with Local Processing: The onboard microprocessor enables complex drive control algorithms to execute locally without burdening the main turbine control processors. This distributed processing architecture ensures rapid response to drive faults or load changes—typically within milliseconds—maintaining turbine stability during auxiliary system transients. For control engineers, this means predictable drive behavior and deterministic fault handling that integrates seamlessly with the Mark IV’s protective systems.

Non-Volatile Firmware Architecture: The EPROM-based firmware storage ensures that drive control algorithms remain intact during power outages or system restarts. Unlike volatile memory requiring battery backup, these devices retain programming indefinitely. When firmware updates are required, the socketed EPROMs can be removed and reprogrammed using standard PROM programming equipment, allowing field updates without replacing the entire board. This architecture supports long-term maintainability of legacy turbine installations where software revisions may be required to address operational issues or equipment changes.

Robust TTL Logic Interfacing: The integrated TTL devices provide standardized logic levels for communication between the microprocessor, memory devices, and external interface circuits. This logic standardization ensures compatibility with the broader Mark IV ecosystem while providing noise immunity through defined logic thresholds. For field technicians, the standardized logic levels simplify troubleshooting using common digital multimeters and logic probes, reducing diagnostic time during maintenance activities.

Modular Maintenance Design: The board features socketed EPROM modules that can be transferred from a failed board to a replacement unit, preserving site-specific calibration data and firmware revisions. The retention levers ensure positive engagement with the rack backplane while facilitating safe extraction during hot-swap procedures. This design minimizes spare parts inventory requirements—replacement boards can be stocked without pre-programmed firmware, with the specific site configuration transferred from the old board at installation time.

Comprehensive Diagnostic Access: Multiple test points distributed across the board surface provide access to critical signals including clock oscillators, address buses, data lines, and control strobes. During troubleshooting, technicians can verify microprocessor operation, memory access cycles, and logic state transitions using standard oscilloscopes or logic analyzers. This visibility supports root cause analysis of intermittent faults that might otherwise require complete board replacement.

Part 5: Typical Applications

Gas Turbine Auxiliary Drive Control:

The board is deployed in GE Frame 5, 6, and 7 gas turbines to control electrically-driven auxiliary systems such as lube oil pumps, hydraulic power units, and cooling fans. In these applications, the microprocessor manages soft-start sequences to prevent mechanical shock to pump couplings and piping systems, while monitoring current and speed feedback for bearing wear detection. The EPROM-stored algorithms implement load-shedding strategies during turbine startup, ensuring that auxiliary power demands do not overload the starting system or compromise acceleration rates to synchronous speed.

The board is deployed in GE Frame 5, 6, and 7 gas turbines to control electrically-driven auxiliary systems such as lube oil pumps, hydraulic power units, and cooling fans. In these applications, the microprocessor manages soft-start sequences to prevent mechanical shock to pump couplings and piping systems, while monitoring current and speed feedback for bearing wear detection. The EPROM-stored algorithms implement load-shedding strategies during turbine startup, ensuring that auxiliary power demands do not overload the starting system or compromise acceleration rates to synchronous speed.

Variable Frequency Drive (VFD) Coordination:

For facilities utilizing VFDs on feedwater pumps or cooling tower fans, the board provides the discrete and analog interfaces necessary for start/stop control and speed reference signals. The TTL logic circuits buffer the Mark IV’s digital outputs from the electrical noise generated by VFD switching, while the microprocessor implements custom ramp profiles to prevent water hammer in piping systems or excessive thermal cycling in heat exchangers. The 34-pin front connector facilitates breakout to terminal blocks for field wiring to VFD control terminals.

For facilities utilizing VFDs on feedwater pumps or cooling tower fans, the board provides the discrete and analog interfaces necessary for start/stop control and speed reference signals. The TTL logic circuits buffer the Mark IV’s digital outputs from the electrical noise generated by VFD switching, while the microprocessor implements custom ramp profiles to prevent water hammer in piping systems or excessive thermal cycling in heat exchangers. The 34-pin front connector facilitates breakout to terminal blocks for field wiring to VFD control terminals.

Steam Turbine Electro-Hydraulic Control Interface:

In steam turbine applications, the board interfaces with electro-hydraulic control systems governing steam admission valves. It processes position feedback from linear variable differential transformers (LVDTs) and outputs analog commands to servo amplifiers. The microprocessor diagnostic capabilities detect stuck valves or sluggish servo response through position deviation analysis, generating alarms before the condition affects turbine control stability. The 40-pin surface connector typically interfaces with signal conditioning boards handling the high-resolution analog signals required for precise valve control.

In steam turbine applications, the board interfaces with electro-hydraulic control systems governing steam admission valves. It processes position feedback from linear variable differential transformers (LVDTs) and outputs analog commands to servo amplifiers. The microprocessor diagnostic capabilities detect stuck valves or sluggish servo response through position deviation analysis, generating alarms before the condition affects turbine control stability. The 40-pin surface connector typically interfaces with signal conditioning boards handling the high-resolution analog signals required for precise valve control.

Aeroderivative Package Control:

For LM6000 and LM2500 units, the board manages the complex sequencing of package auxiliaries including fuel forwarding pumps, compartment ventilation, and starter systems. The EPROM firmware implements the specific starting sequences and protective interlocks required for aeroderivative turbines, which differ significantly from heavy-duty frame units. The board’s vibration-resistant mounting and retention system ensures reliable operation in the higher-frequency vibration environments typical of aeroderivative installations on offshore platforms or peaking power applications.

For LM6000 and LM2500 units, the board manages the complex sequencing of package auxiliaries including fuel forwarding pumps, compartment ventilation, and starter systems. The EPROM firmware implements the specific starting sequences and protective interlocks required for aeroderivative turbines, which differ significantly from heavy-duty frame units. The board’s vibration-resistant mounting and retention system ensures reliable operation in the higher-frequency vibration environments typical of aeroderivative installations on offshore platforms or peaking power applications.

Excitation System Control:

In generator applications, the board controls static excitation systems or brushless exciter field circuits. It manages field flashing sequences during turbine startup and regulates field current during synchronization and load operation. The microprocessor implements over-excitation limiting (OEL) and volts-per-hertz (V/Hz) protection algorithms stored in EPROM, protecting the generator from overheating during startup or overvoltage during load rejection events.

In generator applications, the board controls static excitation systems or brushless exciter field circuits. It manages field flashing sequences during turbine startup and regulates field current during synchronization and load operation. The microprocessor implements over-excitation limiting (OEL) and volts-per-hertz (V/Hz) protection algorithms stored in EPROM, protecting the generator from overheating during startup or overvoltage during load rejection events.