Description

This board belongs to the DS3800 series of the Mark IV platform, designed for heavy-duty gas turbines (Frame 3, 5, 6, 7, 9) and LM aeroderivative units. The platform’s deterministic control architecture requires that drive interfaces maintain signal integrity within milliseconds to ensure stable turbine operation. The board supports hot-swappable maintenance when properly sequenced with the TMR system, allowing drive calibration circuits to be serviced without requiring turbine shutdown or process interruption.

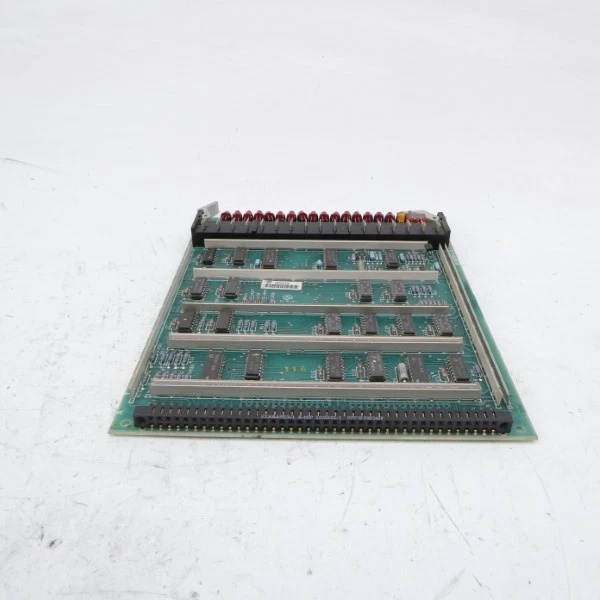

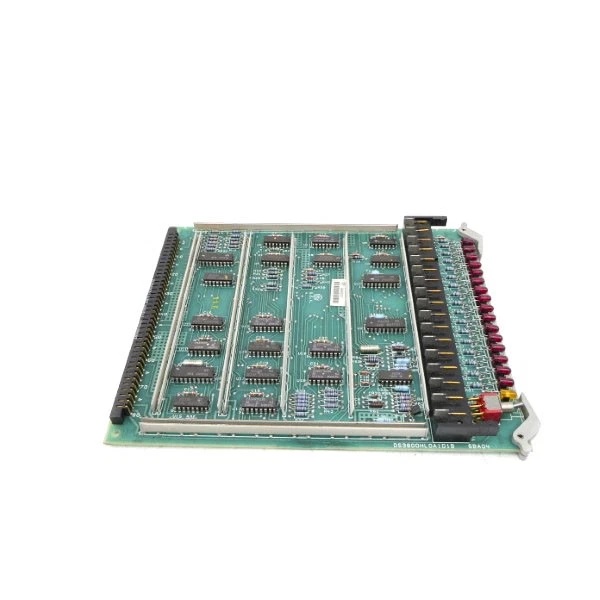

GE DS3800HLOA1D1B

-

Model Number: DS3800DDIB1B1C

-

Manufacturer: General Electric

-

Product Type: Auxiliary Drive Interface Control Board

-

Series: GE Speedtronic Mark IV

-

Signal Conditioning: 8 trimmer potentiometers (trimpots) for field calibration of circuit parameters

-

Configuration: 2 hardware jumpers for operational mode selection

-

Test Access: 9 test points for signal monitoring and calibration verification

-

Passive Components: 12 fixed resistors (support circuitry), ceramic capacitors for noise filtering

-

Backplane Interface: High-density modular connector with retention levers

-

Calibration Tooling: Requires small flat-blade screwdriver and calibrated test equipment

-

Physical Dimensions: Approximately 8.25 cm × 4.15 cm (standard Mark IV form factor)

-

Operating Temperature: -40°C to +70°C (industrial grade)

-

Humidity: 5% to 95% non-condensing

-

Mounting: Standard Mark IV rack slot with locking retention hardware

Part 4: Core Features & Customer Value

Robust Signal Conditioning for Industrial Environments: The board integrates passive filtering components to attenuate electrical noise from variable frequency drives and high-power switching equipment that could corrupt analog signals. This filtering ensures that 4-20mA command signals or ±10VDC velocity references remain stable despite electromagnetic interference common in turbine enclosures. For plant operators, this translates to stable auxiliary drive performance without hunting, oscillation, or position drift that could affect fuel control accuracy or generator excitation stability.

GE DS3800HLOA1D1B

Part 5: Typical Applications

The DS3800DDIB1B1C is deployed in GE Frame 5, 6, and 7 gas turbines to interface between the Mark IV control system and electro-hydraulic fuel valve servos. In these applications, the board processes the 4-20mA or ±10VDC command signals generated by the fuel control algorithms and scales them to match specific servo amplifier requirements. The trimmer resistors allow field calibration to compensate for variations in servo response characteristics between different valve manufacturers or wear patterns in aging equipment. The board also conditions position feedback signals from linear variable differential transformers (LVDTs) within the valve actuators, ensuring accurate valve position reporting for closed-loop control and fuel metering calculations.

In turbine-generator applications utilizing static excitation systems or brushless exciters, this board provides the analog interface between the Mark IV voltage regulator and the excitation power electronics. It processes the field current command signals and conditions feedback from field current sensors or voltage regulators. The calibration trimmers enable precise matching of the interface gain to the specific exciter response, preventing voltage regulation instability or overshoot during grid disturbances. The board’s test points facilitate verification of excitation system response during commissioning and periodic maintenance testing required by grid codes.

For auxiliary systems such as lube oil pumps, cooling fans, or hydraulic power units driven by VFDs, the board interfaces the Mark IV’s start/stop commands and speed references with the drive control terminals. It provides electrical isolation and signal buffering to protect the sensitive Mark IV logic from VFD-generated electrical noise. The calibration features allow adjustment of speed reference scaling to match different motor base speeds or operational ranges, while the test points enable verification of commanded vs. actual speeds during VFD commissioning and troubleshooting.

In steam turbine applications within petrochemical facilities and power plants, the board interfaces with auxiliary drives controlling feedwater pumps, condensate pumps, and cooling water systems. It processes analog commands for variable speed drives and discrete status feedback from motor control centers. The field-calibration capability ensures compatibility with existing plant drive infrastructure during control system retrofits, allowing the Mark IV to interface with legacy 1970s-era drive equipment without requiring complete drive replacement, thereby reducing capital costs during modernization projects.