Description

Professional Product Description: GE DS200DDTBG2A Digital I/O Terminal Board

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE DS200DDTBG2A |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | High-Density Digital I/O Terminal Board (Mark VIe Series Compatibility) |

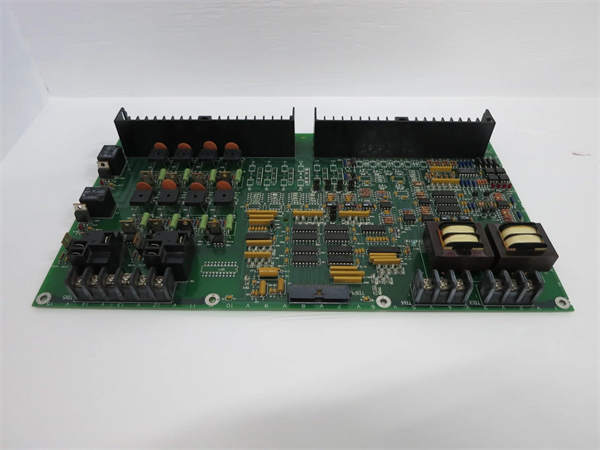

| I/O Channel Configuration | 32 digital input channels + 16 digital output channels (48 total, fully isolated) |

| Input Signal Specifications | 24V DC sinking/sourcing; Dry contact (NO/NC); Response time: <2ms; Input current: 5mA typical (24V DC) |

| Output Signal Specifications | 24V DC, 2A per channel (continuous); 5A per channel (peak, 5s); Solid-state (MOSFET) with short-circuit auto-recovery |

| Protection Features | Input over-voltage protection (up to 40V DC); Output short-circuit/latch-up protection; ESD protection (±15kV contact, ±25kV air); Reverse polarity protection |

| Interface Type | 1x 64-pin DIN 41612 connector (for Mark VIe I/O modules: GE IS420YDIAS1B, GE IS420YDOAS1B); 48x screw-terminal blocks (field wiring); 1x local reset button |

| Physical Dimensions (H×W×D) | 240mm × 170mm × 35mm; Weight: 420g |

| Installation Method | Panel mounting (4x M4 screws, torque: 0.6–0.9 N·m); Compatible with Mark VIe control cabinets; Minimum clearance: 35mm (rear) for wiring |

| Operating Temperature Range | -20°C to +70°C (ambient); -40°C to +85°C (short-term storage, <72h) |

| Relative Humidity Tolerance | 5% – 95% RH (non-condensing); Conformal-coated PCB (IP20 protection) |

| Certifications | CE, UL 508C, IEC 61010-1, ATEX Zone 2, IEC 61508 (SIL 2 Compatible), NQA-1 (nuclear-grade option) |

| Compatibility | GE Mark VIe ecosystem: GE IC698CPE040-FJGE (CPU), GE DS200EXPSG1A (power supply); Field devices: Proximity sensors, solenoid valves, pumps, relays |

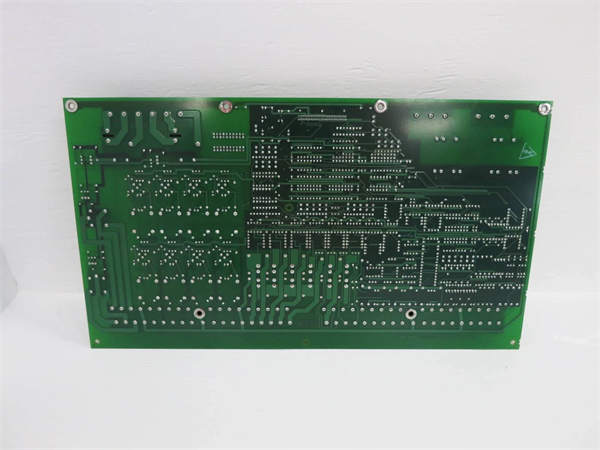

GE DS200DDTBG2A

Product introduction

GE DS200DDTBG2A is a high-performance digital I/O terminal board engineered exclusively for GE’s Mark VIe control system—GE’s flagship platform for mission-critical industrial automation. As a upgraded variant of lower-density terminal boards (e.g., GE DS200DTBAG1A), GE DS200DDTBG2A integrates 32 input and 16 output channels into a single panel-mount unit, solving the challenge of space constraints in large-scale control systems while ensuring robust signal protection.

In industrial setups, GE DS200DDTBG2A acts as a “signal hub” between field devices and core Mark VIe I/O modules. It organizes wiring from sensors (e.g., pressure switches, limit detectors) and actuators (e.g., valve solenoids, motor starters), filters electrical noise, and shields expensive I/O modules (like GE IS420YDIAS1B) from wiring errors or short circuits. Unlike generic terminal blocks, GE DS200DDTBG2A is optimized for Mark VIe’s signal protocols, ensuring seamless data transmission with minimal latency—critical for applications like power plant turbine control or oil refinery process loops, where unplanned downtime costs can exceed $100,000 per hour.

What sets GE DS200DDTBG2A apart is its balanced density and usability: it offers 50% more input channels than entry-level models without sacrificing access to terminal blocks or diagnostic features. This makes it ideal for mid-to-large automation systems that require both expanded I/O coverage and reliable operation in harsh industrial environments.

Core advantages and technical highlights

High-Density Design for Space Optimization

GE DS200DDTBG2A’s 48 total channels (32I/16O) in a single unit reduce cabinet space usage by 40% compared to using separate 16-channel input and output boards. For example, a natural gas processing plant monitoring 32 pressure sensors (inputs) and controlling 16 valve actuators (outputs) would need four low-density boards—whereas GE DS200DDTBG2A handles all signals in one slot. This not only shrinks the control cabinet footprint but also simplifies wiring (fewer cables to route) and cuts installation time by 30%, a key advantage for retrofits or tight-space installations like offshore platforms.

Solid-State Outputs for Durability and Silent Operation

Equipped with MOSFET solid-state outputs, GE DS200DDTBG2A delivers 2A continuous current per channel—enough to power small motors or heavy-duty solenoids—while operating silently and lasting 10x longer than mechanical relays. In a food processing plant’s packaging line, where noise pollution is restricted (to comply with workplace regulations) and equipment runs 24/7, the silent outputs avoid disrupting production, and the long lifespan reduces replacement frequency by 80% compared to relay-based boards. The outputs also include auto-recovery from short circuits: if a valve actuator shorts, GE DS200DDTBG2A limits current to safe levels and resumes operation once the fault is cleared—no manual reset required.

Enhanced Isolation and Noise Immunity

Each channel of GE DS200DDTBG2A features independent isolation (250V AC channel-to-channel, 500V AC channel-to-ground), which blocks ground loops and electromagnetic interference (EMI) from nearby motors or high-voltage equipment. In a steel mill, where EMI levels are extreme due to arc furnaces, GE DS200DDTBG2A’s isolation ensures that 24V DC sensor signals remain accurate within ±1%—preventing false alarms or incorrect control actions. The board also includes built-in low-pass filtering (60Hz/50Hz selectable) to eliminate grid-related noise, further improving signal integrity for time-critical applications like turbine speed monitoring.

Local Reset and Diagnostic Visibility

GE DS200DDTBG2A includes a front-panel reset button and 48 individual LED indicators (green for active inputs, red for energized outputs) for at-a-glance troubleshooting. If a short circuit triggers an output fault, technicians can reset the affected channel locally without powering down the entire system—saving 1–2 hours of downtime per incident. The LEDs also let operators quickly verify signal status: for example, in a water treatment plant, a dark input LED immediately identifies a failed flow sensor, allowing for faster repairs than relying solely on remote HMI data.

Typical application scenarios

Power Plant Turbine Auxiliary Control

In a 600MW coal-fired power plant, GE DS200DDTBG2A is installed in the turbine control cabinet to manage 32 auxiliary system inputs and 16 outputs. Input channels monitor lube oil pressure switches (8), bearing temperature sensors (12), and emergency stop buttons (12); output channels control lube oil pumps (4), cooling fans (6), and alarm buzzers (6). The board’s isolation protects the Mark VIe I/O module from voltage transients caused by turbine startup, while its solid-state outputs ensure reliable pump activation during peak load periods.

During a routine startup, a technician accidentally crosses a 120V AC wire with a sensor cable—triggering GE DS200DDTBG2A’s over-voltage protection. The board latches the affected input channel, illuminates a fault LED, and alerts the control room via the Mark VIe CPU. The technician resets the channel locally, and the turbine resumes startup within 15 minutes—avoiding a 4-hour shutdown that would have cost the plant $400,000 in lost generation.

Offshore Wind Farm Nacelle Control

In an offshore wind farm’s turbine nacelle (a harsh environment with salt spray, vibration, and temperature swings), GE DS200DDTBG2A monitors 32 blade pitch position sensors (inputs) and controls 16 pitch actuators (outputs). Its conformal-coated PCB resists corrosion, and its -20°C to +70°C operating range handles winter cold and summer heat. The board’s low-pass filtering eliminates noise from the turbine’s generator, ensuring accurate pitch sensor data—critical for optimizing wind capture and preventing blade damage during high winds. If a pitch actuator short-circuits, GE DS200DDTBG2A’s auto-recovery feature restores operation once the fault is fixed, keeping the turbine online and maximizing energy production.

GE DS200DDTBG2A

Related model recommendations

GE IS420YDIAS1B: Mark VIe digital input module that receives conditioned signals from GE DS200DDTBG2A’s 32 input channels; transmits data to the GE IC698CPE040-FJGE CPU.

GE IS420YDOAS1B: Mark VIe digital output module that sends control commands to GE DS200DDTBG2A’s 16 output channels; drives field actuators like valves or pumps.

GE DS200EXPSG1A: Power supply expansion module that provides stable 24V DC to GE DS200DDTBG2A and connected field devices; ensures reliable operation during voltage fluctuations.

GE IC698CPE040-FJGE: Mark VIe CPU that processes data from GE DS200DDTBG2A (via I/O modules) and executes control logic for critical systems (e.g., turbine, wind farm).

GE DS200DTBAG1A: 24-input terminal board (entry-level variant of GE DS200DDTBG2A); ideal for small-scale applications requiring fewer channels (e.g., standalone pumps).

GE DS200TERMG6: Terminal block accessory kit for GE DS200DDTBG2A; includes cage-clamp wire adapters (tool-less wiring), spare screws, and ESD-safe gloves.

GE IC698CMX016: Mark VIe backplane module that hosts GE IS420YDIAS1B and GE IS420YDOAS1B; enables seamless communication with GE DS200DDTBG2A.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing GE DS200DDTBG2A, confirm compatibility with the Mark VIe I/O modules (e.g., GE IS420YDIAS1B) and control cabinet environment (-20°C to +70°C, 5%–95% RH non-condensing). Required tools: torque screwdriver (0.6–0.9 N·m for terminal blocks), wire strippers (22–14 AWG), ESD-safe gloves, multimeter, and alcohol wipes (for cleaning terminals). Safety precautions: Power off the Mark VIe system (lockout/tagout) to avoid electrical shock; Mount GE DS200DDTBG2A to the cabinet using M4 screws (ensure 35mm rear clearance for wiring); Connect the board’s ground terminal to the cabinet ground (≥12 AWG wire) for ESD protection; Label field wires (e.g., “SENSOR-IN-15,” “VALVE-OUT-08”) to match the board’s channel labels—use shielded twisted-pair cable for input wiring to minimize EMI.

Maintenance suggestions

For daily operation, check GE DS200DDTBG2A’s LEDs: ensure power LED (amber) is on, input LEDs match sensor status (green = active), and output LEDs align with actuator commands (red = energized). Every 3 months, inspect terminal blocks for loose wiring (retorque to 0.6–0.9 N·m) and clean the board with a dry lint-free cloth (avoid liquids, which can damage conformal coating). If a channel fault occurs (e.g., output short), first disconnect the field device and test with a multimeter—if the fault persists, press the local reset button; replace GE DS200DDTBG2A with a GE-approved spare only if multiple channels fail (third-party boards may not meet SIL 2 or NQA-1 standards). Annual maintenance should include verifying isolation integrity with a megohmmeter (≥100MΩ at 500V DC) to ensure no degradation of channel isolation.

Service and guarantee commitment

GE DS200DDTBG2A comes with a 48-month manufacturer’s warranty from GE, covering defects in materials, workmanship, and performance under normal industrial use (per UL 508C and IEC 61508 standards). If GE DS200DDTBG2A fails within the warranty period, GE provides a “rapid swap” service—pre-tested replacement units are shipped within 48 hours for priority customers (e.g., power plants, nuclear facilities)—minimizing system downtime.

GE offers 24/7 global technical support for GE DS200DDTBG2A, with specialists available via phone/email to assist with installation, troubleshooting, or reset procedures. Customers receive free access to GE’s Proficy Machine Edition software updates (for system configuration) and the Mark VIe terminal board technical manual for 2 years post-purchase. For enhanced reliability, GE’s Mark VIe Care Program includes annual on-site inspections of GE DS200DDTBG2A—verifying terminal torque, LED functionality, and isolation performance—reflecting GE’s confidence in the board’s durability and commitment to keeping critical industrial systems operational.