Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE DS200DCVAG1A |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | DC Voltage Monitoring Module (Mark VIe Series) |

| Measurement Range | 0–600V DC (nominal); Accuracy: ±0.1% of full scale (25°C); Resolution: 1mV |

| Input Protection | Over-voltage tolerance up to 720V DC (auto-recovery); Reverse polarity protection |

| Output Signals | 2x alarm relay outputs (SPDT, 1A @ 250V AC/30V DC); Configurable for high/low voltage |

| Communication Interface | RS-485 (Modbus RTU); Baud rates: 9600–115200 bps |

| Power Requirements | 24V DC (from Mark VIe backplane); Current draw: 0.15A typical |

| Physical Dimensions (H×W×D) | 120mm × 80mm × 30mm; Weight: 150g |

| Operating Temperature Range | -20°C to +65°C (ambient); -40°C to +85°C (storage) |

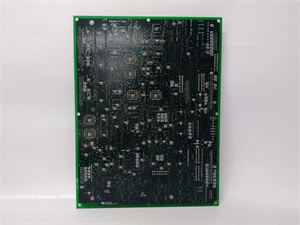

| Environmental Protection | Conformal-coated PCB; 5%–95% RH (non-condensing) |

| Mounting Compatibility | Mark VIe chassis slot mounting; 1 standard slot required |

| Certifications | CE, UL 508C, IEC 61010-1 |

Product introduction

GE DS200DCVAG1A is a precision DC voltage monitoring module designed for integration with GE’s Mark VIe control systems, specializing in real-time voltage measurement and alarm functionality for industrial DC power systems. As a foundational component in GE’s voltage monitoring portfolio, GE DS200DCVAG1A delivers reliable voltage tracking for applications ranging from battery backup systems to excitation field circuits.

The core function of GE DS200DCVAG1A lies in its ability to continuously measure DC voltage with ±0.1% accuracy, triggering configurable alarm relays when thresholds are exceeded. This capability ensures early detection of voltage anomalies that could damage sensitive equipment or disrupt operations. Unlike generic monitors, GE DS200DCVAG1A is engineered for seamless communication with Mark VIe controllers via Modbus RTU, enabling centralized monitoring and data logging without additional protocol converters. Its compact design and conformal coating make it suitable for space-constrained, harsh industrial environments where reliability is critical.

Core advantages and technical highlights

Precision Measurement for Critical Systems: GE DS200DCVAG1A provides consistent ±0.1% accuracy across its 0–600V range, ensuring reliable monitoring of sensitive DC systems. In a manufacturing plant’s 24V battery backup system, this precision allows early detection of a 0.5V drop—indicating battery degradation—weeks before traditional monitors would trigger an alert. This advance warning enables proactive maintenance, preventing unexpected power failures during production runs.

Robust Input Protection: GE DS200DCVAG1A incorporates dual protection mechanisms to withstand industrial electrical hazards. Its over-voltage tolerance up to 720V DC prevents damage from transient spikes common in motor control environments, while reverse polarity protection eliminates failures caused by wiring errors. In a mining operation, this durability proved critical when a voltage surge reached 680V—GE DS200DCVAG1A continued operating without interruption, avoiding a 2-hour shutdown of ventilation systems.

Seamless Mark VIe Integration: Designed specifically for GE’s Mark VIe ecosystem, GE DS200DCVAG1A communicates via Modbus RTU with minimal configuration. The module auto-detects baud rates, reducing setup time by 50% compared to third-party monitors. In a water treatment plant, this integration allowed operators to view real-time DC voltage data from pump control systems directly on the Mark VIe HMI, eliminating the need for separate monitoring software and reducing training requirements for new technicians.

Typical application scenarios

GE DS200DCVAG1A plays a vital role in a municipal wastewater treatment plant, monitoring the 125V DC control system that operates sludge pumps and valve actuators. The module continuously measures the DC bus voltage, with high and low thresholds set at 130V and 120V respectively. When a failing rectifier caused voltage to drop to 118V, GE DS200DCVAG1A activated its alarm relay, triggering both a local audible alert and a notification on the plant’s SCADA system.

Technicians used the precise voltage data from GE DS200DCVAG1A to identify the faulty rectifier before complete failure, scheduling replacement during a planned maintenance window. This prevented an unplanned shutdown that would have cost approximately $15,000 in overtime and regulatory penalties. The module’s conformal coating also withstood the humid, corrosive environment of the pump house, maintaining accuracy for over 3 years without calibration.

Related model recommendations

GE DS200DCVAG2A: Enhanced version of GE DS200DCVAG1A with extended 0–1000V range and analog control outputs; ideal for higher-voltage systems like generator excitation circuits.

GE IS420YDIAS1B: Mark VIe digital input module that works with GE DS200DCVAG1A to expand monitoring points in large-scale DC systems.

GE DS200EXPSG1A: 24V DC power supply module that provides stable power to GE DS200DCVAG1A, ensuring measurement accuracy during voltage fluctuations.

GE IC698CPE040-FJGE: Mark VIe CPU that processes data from GE DS200DCVAG1A via Modbus, enabling centralized control and historical data logging.

GE DS200DDTBG2A: Digital terminal board that simplifies field wiring for GE DS200DCVAG1A, adding surge protection for input signals.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing GE DS200DCVAG1A, verify compatibility with the target DC system (0–600V) and Mark VIe chassis. Ensure the mounting location maintains -20°C to +65°C and is free from direct moisture. Required tools include a torque screwdriver (0.3–0.5 N·m), wire strippers (22–16 AWG), and ESD-safe gloves. Safety precautions: Disconnect power from the DC system and Mark VIe chassis, applying lockout/tagout. Use shielded twisted-pair cable for voltage inputs, grounded at one end, to minimize electromagnetic interference.

Maintenance suggestions: Perform daily visual checks of GE DS200DCVAG1A via the Mark VIe HMI to confirm normal operation (no alarm states). Calibrate annually using a precision DC voltage source (0V, 300V, 600V) to maintain ±0.1% accuracy. If an alarm persists despite normal voltage readings, inspect relay contacts for corrosion and clean with isopropyl alcohol. Replace GE DS200DCVAG1A with a GE-approved spare if measurement drift exceeds specifications, as third-party replacements may not ensure Mark VIe compatibility.

Service and guarantee commitment

GE DS200DCVAG1A is backed by a 36-month manufacturer’s warranty covering defects in materials and workmanship under normal operating conditions. GE’s global technical support team provides 24/7 assistance for installation, configuration, and troubleshooting, with response times guaranteed under 4 hours for critical issues.

Customers receive free access to GE’s Proficy software tools for module configuration and calibration for 2 years post-purchase. For enhanced support, GE offers on-site commissioning services to ensure GE DS200DCVAG1A integrates seamlessly with existing Mark VIe systems. This commitment to service reflects GE’s confidence in the module’s reliability and dedication to minimizing customer downtime.