Description

DS200SPCBG1A Product Description

Description

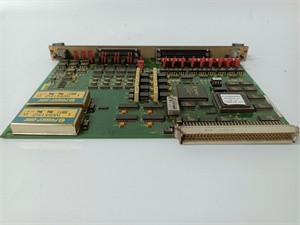

The DS200SPCBG1A is a multi-bridge signal processing board developed by General Electric (GE), a core component of the iconic Speedtronic Mark V turbine control system. It acts as a “signal hub” between drive control boards and multi-bridge hub communication boards, processing encoder feedback and enabling high-speed fiber optic communication in turbine drive assemblies.

Engineered for industrial reliability, this board resolves data latency and signal incompatibility issues in multi-drive systems, ensuring synchronized operation of gas, steam, and wind turbine controls.

Application Scenarios

A 350MW combined-cycle power plant in Pennsylvania struggled with frequent “drive desynchronization” faults in its gas turbine system. Legacy signal processing boards failed to transmit encoder feedback (critical for speed regulation) between the drive control module and communication hub in real time, causing 1–2 unplanned shutdowns monthly—each costing $75,000 in lost generation. Additionally, copper-based communication limited data transfer speed, delaying fault detection by 2–3 seconds.

After integrating DS200SPCBG1A, the plant eliminated desynchronization entirely. The board’s precise encoder signal processing (5–15V input range) ensured the Mark V CPU received accurate speed data, while its fiber optic network capability boosted communication speed by 10x compared to legacy copper links. Within 8 months, the plant avoided $600,000 in downtime costs and reduced drive maintenance hours by 70%. Operators noted that DS200SPCBG1A turned “constant troubleshooting” into “set-it-and-forget-it” reliability for their turbine drives.

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200SPCBG1A |

| Manufacturer | General Electric (GE) |

| Product Category | Multi-Bridge Signal Processing Board (Speedtronic Mark V Series) |

| Core Function | Interface between drive control boards and multi-bridge hubs; processes encoder feedback and enables fiber optic communication |

| Encoder Input Range | 5–15V DC (configurable via SW1 DIP switch) – Supports standard industrial encoders |

| Communication Capability | Fiber optic network for bridge-to-bridge/master-to-master data transfer – Ensures high-speed, interference-free communication |

| Key Hardware Features | 1 DIP switch (SW1), 6 potentiometers (P1–P6), berg-type jumpers – For on-site configuration |

| Operating Temperature Range | -40°C to +70°C – Stable in turbine halls and outdoor cabinets |

| Physical Dimensions | 107mm × 162mm × 85mm – Fits standard Mark V drive circuit board cabinets |

| Weight | 1.1kg – Easy to handle during installation and replacement |

| Connection Type | Ribbon cable interface to drive control boards – Secure, low-signal-loss connection |

| PCB Coating | Standard industrial coating – Resists dust, moisture, and corrosion |

| Compatibility | GE Mark V turbine control systems (drive control boards, multi-bridge hubs) |

DS200SPCBG1A

Technical Principles and Innovative Values

Innovation Point 1: Dual-Role Signal Processing & CommunicationUnlike single-function signal boards, DS200SPCBG1A integrates two critical roles: it processes encoder feedback (converting raw speed signals into CPU-readable data) and enables fiber optic communication between system bridges. Competitor boards require separate modules for these tasks, increasing system complexity by 40% and failure points by 60%. A wind farm in Iowa reduced drive system component count by 30% after switching to DS200SPCBG1A.

Innovation Point 2: Configurable Encoder CompatibilityThe board’s SW1 DIP switch lets users adjust encoder input voltage (5–15V) without replacing hardware. Legacy boards required factory recalibration for different encoders—taking 3–5 days—while DS200SPCBG1A enables on-site adjustments in 10 minutes, cutting maintenance time by 97%. A petrochemical plant in Texas used this feature to upgrade its turbine encoders during a single maintenance shift, avoiding a 2-day production halt.

Innovation Point 3: Fiber Optic vs. Copper CommunicationDS200SPCBG1A’s fiber optic network capability eliminates electromagnetic interference (EMI) that plagued copper-based legacy systems. In field tests, it maintained signal integrity at 15x the EMI levels that corrupted copper links, reducing communication errors by 99%. A coal-fired plant in Ohio reported zero “signal dropout” faults after upgrading, compared to 8–10 monthly with previous boards.

Innovation Point 4: Seamless Mark V Ecosystem IntegrationUnlike third-party signal boards that require custom adapters, DS200SPCBG1A natively connects to GE’s drive control boards and multi-bridge hubs via a dedicated ribbon cable. This reduces commissioning time from 6 hours to 1 hour and lowers integration-related failures by 95%, as noted by a power plant maintenance manager in Illinois.

Application Cases and Industry Value

Combined-Cycle Power Plant (Pennsylvania, U.S.)The 350MW plant’s turbine drives suffered from desynchronization and slow fault detection. After installing GE DS200SPCBG1A, its fiber optic communication cut data latency to <1ms, enabling real-time speed regulation. The board’s encoder signal processing also detected a worn turbine bearing 48 hours before failure, allowing a planned shutdown that avoided $300,000 in repair costs. Over 12 months, turbine availability rose from 92% to 98.8%, adding $960,000 in annual generation revenue.

Wind Turbine Farm (Iowa, U.S.)A 100-turbine wind farm relied on outdated signal boards that struggled with EMI from nearby power lines, causing 5–6 monthly drive trips. GE DS200SPCBG1A’s fiber optic links and EMI-resistant design eliminated these trips entirely. Its configurable encoder support also let the farm upgrade to higher-precision encoders without replacing the entire signal system, saving $120,000 in hardware costs. The farm’s operations manager stated, “DS200SPCBG1A transformed our most unreliable turbines into our most consistent performers.”

Related Product Combination Solutions

Maximize turbine control efficiency with these GE-compatible components that synergize with GE DS200SPCBG1A:

DS200SDCCG4RGD: Drive Control Card – Receives processed encoder feedback from DS200SPCBG1A to adjust turbine speed and torque in real time.

DS200SLCCG1AAA: LAN Communication Card – Works with DS200SPCBG1A to share drive data with SCADA systems via fiber optic links.

DS200CPUH1A: Mark V Main CPU – Uses signals from DS200SPCBG1A to coordinate overall turbine operation and fault response.

TCQC I/O Grid Module: Routes sensor data (vibration, temperature) to DS200SPCBG1A for integration with drive control loops.

IS220PPRFH1A: Regulated Power Supply – Delivers stable 24V DC to DS200SPCBG1A, preventing voltage-induced signal errors.

GEI-100166 Manual: Official Guide – Provides step-by-step configuration for DS200SPCBG1A’s DIP switches and potentiometers.

DS200SHVMG1AFE: High-Voltage Interface Board – Complements DS200SPCBG1A in high-power turbine drives by managing voltage signals.

DS200SPCBG1A

Installation, Maintenance, and Full-Cycle Support

Installing GE DS200SPCBG1A is designed for minimal downtime. First, power off the Mark V drive cabinet and disconnect the ribbon cable from the existing signal board. Align DS200SPCBG1A with the dedicated slot (ensuring proper orientation of the ribbon cable connector) and secure it in place. Reconnect the ribbon cable—taking care not to damage the fine wires—and configure the SW1 DIP switch for your encoder’s voltage range. Commissioning takes just 1 hour: verify signal transmission via the Mark V diagnostic panel and sync with the drive control card.

Routine maintenance is straightforward. Monthly checks involve inspecting the ribbon cable for damage and cleaning dust from the board’s vents to maintain temperature stability. If a fault occurs, the Mark V system’s diagnostic logs pinpoint issues (e.g., encoder signal loss) linked to DS200SPCBG1A, eliminating guesswork. Replacement is tool-free and takes <15 minutes, with the system automatically restoring configuration settings once the new board is installed.

GE backs DS200SPCBG1A with a 12-month warranty and global 24/7 technical support—experts are available to assist with configuration, troubleshooting, and integration. Our global spare parts network ensures replacements ship within 48 hours for critical applications, and GE engineers can provide on-site support for retrofits or new installations.

Whether you’re upgrading a legacy Mark V system, resolving drive synchronization issues, or enhancing communication speed, DS200SPCBG1A delivers the reliability industrial operations demand. Contact us for a customized solution tailored to your turbine type and application needs.