Description

Key Technical Specifications

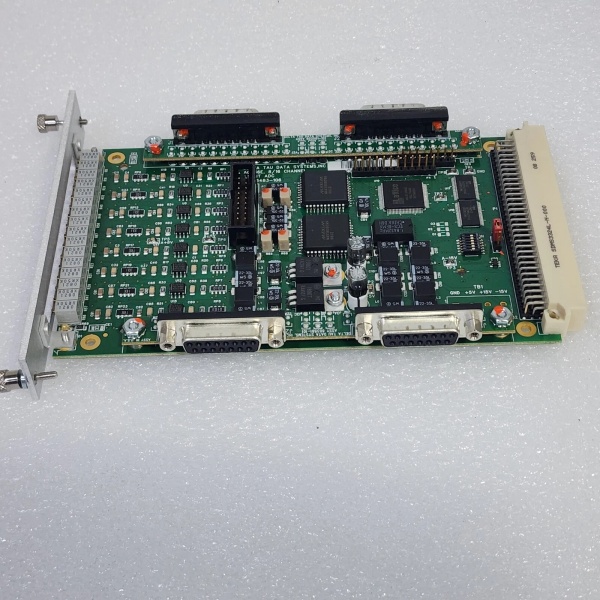

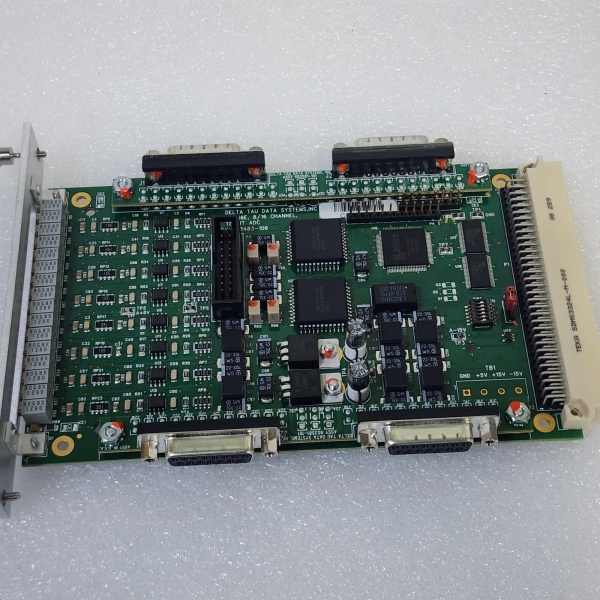

- Channel & Resolution: It supports 8 or 16 channel switching configuration, which can be flexibly adjusted according to different signal acquisition needs. Equipped with a 12-bit ADC chip, this resolution can balance acquisition precision and speed, which is enough to meet the requirements of most industrial analog signal acquisition such as voltage change monitoring and servo system feedback.

- Sampling & Input Performance: The sampling rate of each channel can reach up to 1 MHz, and some sources also record a conversion rate of up to 200 kHz, which can quickly capture the changes of fast-changing analog signals in industrial scenes. The analog input range is fixed at ±10V, and it supports both differential and single-ended input modes. The differential input can effectively reduce external interference and improve the stability of signal acquisition.

- Hardware & Connection: It adopts a 3U Eurocard standard form factor, which is convenient for installation in standard industrial racks. It is connected to the CPU board through the backplane expansion port to realize data transmission and command interaction. It is also equipped with a DIP switch and P3 connector, and supports terminal block options to facilitate users to carry out hardware configuration and wiring operations.

- Auxiliary Functions & Power Supply: The board has on-board signal conditioning function, which can preprocess the collected analog signals to reduce signal distortion. At the same time, it is equipped with on-board memory for data buffering to avoid data loss during high-speed acquisition. The power supply is 24V DC, which is compatible with the power supply system of most industrial control cabinets.

- Operating Environment: As an industrial-grade board, it can adapt to the temperature range of general industrial workshops. It has certain anti-interference performance and can work stably in complex electromagnetic environments on industrial sites.

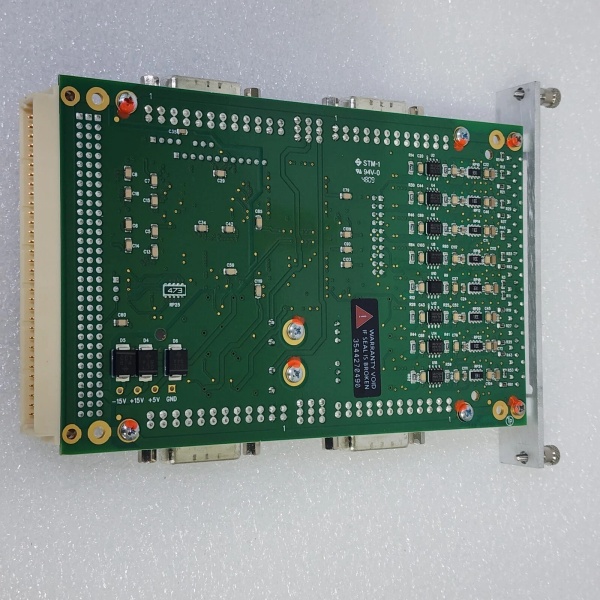

DELTA TAU ACC-36E

Field Application & Problem Solved

In precision manufacturing, industrial testing and other fields, a large number of analog signals such as servo motor speed, equipment running pressure and temperature need to be collected in real time. Traditional low-channel ADC boards can’t meet the multi-signal simultaneous collection requirements, while high-resolution but low-speed products will miss key signal changes.

The ACC-36E well solves these pain points. In CNC machine tools, it can collect the analog feedback signals of multiple servo axes at the same time, and transmit the data to the UMAC controller in real time to ensure the synchronization and precision of the machine tool’s cutting action. In electronic component testing equipment, it can collect the voltage and current signals of multiple test points of the component at the same time, realizing efficient batch testing of components. In addition, in environmental monitoring equipment in the fields of environmental protection and geology, it can collect multiple analog signals such as sensor detection data, providing a reliable data source for subsequent data analysis. Its differential input design also solves the problem of signal interference in complex industrial environments, ensuring the accuracy of acquisition data.

Installation & Maintenance Pitfalls (Expert Tips)

- Address Conflict with Other Boards: When used with the ACC-11E board, if the same chip address is selected for both, the collected data will be overwritten mutually. Before installation, it is necessary to set the DIP switch on the board to assign a unique address to each board, and check the address configuration through the upper computer software to avoid data confusion.

- Incorrect Input Mode Wiring: The board supports both differential and single-ended inputs, and the wiring methods of the two modes are quite different. Many users mix up the wiring during installation, resulting in no signal collection or distorted signals. It is necessary to confirm the input type of the connected sensor first, and refer to the manual to complete the corresponding wiring.

- Ignoring Signal Preprocessing: Although the board has on-board signal conditioning function, for analog signals with large fluctuations or containing strong noise, if no external filtering components are added, the collected data will have large errors. For high-precision application scenarios, it is recommended to connect a low-pass filter between the sensor and the board to optimize the signal quality.

- Backplane Connection Looseness: The board transmits data through the backplane expansion port. After long-term operation of the equipment, vibration may cause the backplane connection to loosen. If the data collection is intermittent during use, it is necessary to shut down the power in time to check the connection between the board and the backplane, and reinsert it firmly to avoid short circuits caused by improper operation.

DELTA TAU ACC-36E

Technical Deep Dive & Overview

The ACC-36E is a cost-effective and highly adaptable ADC board designed for the expansion needs of DELTA TAU’s industrial control system. Its 8/16 channel switchable design is very flexible. Unlike fixed-channel ADC boards, it can be adjusted according to the number of signals to be collected in different projects, reducing the cost of hardware configuration. The 12-bit resolution and up to 1 MHz sampling rate strike a good balance between precision and speed—compared with 8-bit ADC boards, it has higher amplitude measurement accuracy, and compared with 16-bit high-resolution boards, it has more advantages in sampling speed and cost, which is very suitable for mainstream industrial acquisition scenarios.

The on-board signal conditioning circuit is one of its core advantages. It can filter and amplify the weak analog signals collected from sensors, improving the signal-to-noise ratio of the data. The matching on-board memory can temporarily store the collected data, avoiding data loss due to insufficient transmission speed between the board and the controller. In addition, its compatibility with DELTA TAU’s UMAC and other controllers is excellent. It can be directly integrated into the existing control system through the backplane without complex protocol conversion, which greatly reduces the difficulty of system integration for users.

Even in the current market where there are many new ADC modules, the ACC-36E is still widely used in the transformation and maintenance of legacy industrial equipment because of its stable performance and perfect compatibility. It is an important supporting component to ensure the continuous and reliable operation of precision industrial control systems.