Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 3500/05-01-01-00-00-00 |

| Manufacturer | Bently Nevada |

| Product category | Rack interface module |

| Electrical performance | 24V DC power supply (from 3500/15 127610-01); Power consumption: 3.5W max |

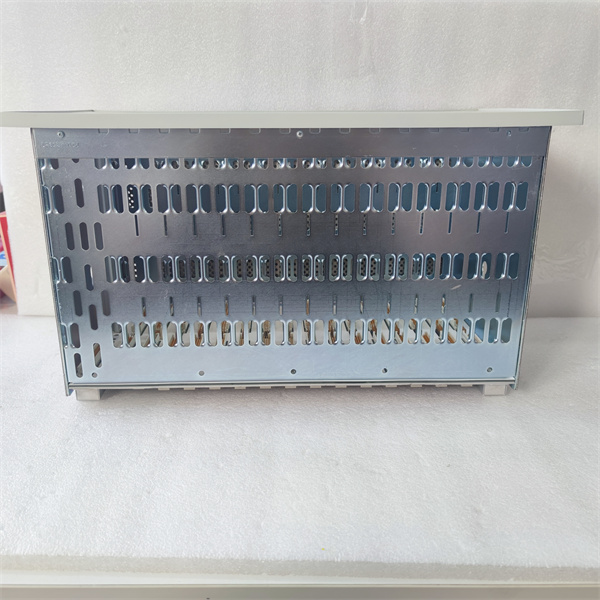

| Physical size | Width: 24.4mm, Height: 241.3mm, Depth: 242mm |

| Interface type | Backplane connector for 3500 series rack; 10/100Base-T Ethernet port; RS-485 serial port |

| Communication protocols | Modbus TCP/IP; Bently Nevada proprietary protocol; ASCII |

| Data transfer rate | Ethernet: 100 Mbps; RS-485: 115.2 kbps max |

| Environmental requirements | Operating temperature: -40°C to +70°C; Humidity: 5% – 95% (non-condensing) |

| Installation method | Rack-mountable in 3500 series racks; Occupies 1 standard slot |

| Compatibility | Works with 330851-02-000-060-10-00-00, 3500/33-01-00, 3500/42M 140734-02, and 170180-01-00 software |

BENTLY 3500/05-01-01-00-00-00

Product introduction

The Bently Nevada 3500/05-01-01-00-00-00 is a critical rack interface module, serving as the communication gateway for the 3500 series machinery protection system. It facilitates data exchange between the rack’s internal modules and external systems, enabling centralized monitoring, configuration, and control of industrial machinery protection networks.

Designed as the “nerve center” of the 3500 ecosystem, the 3500/05-01-01-00-00-00 aggregates data from sensors like the 330851-02-000-060-10-00-00 proximity transducer, processes it via modules such as the 3500/42M 140734-02 and 3500/33-01-00, and transmits it to upstream systems like SCADA or 170180-01-00 software. Its dual communication ports (Ethernet and RS-485) ensure flexible integration with both modern digital networks and legacy systems.

Powered by the reliable 3500/15 127610-01 redundant power supply, the 3500/05-01-01-00-00-00 ensures uninterrupted data flow—critical for real-time decision-making in safety-critical applications. Its rugged design and wide operating temperature range make it suitable for harsh industrial environments, from power plants to offshore platforms.

Core advantages and technical highlights

Dual-protocol communication: The 3500/05-01-01-00-00-00 supports both Modbus TCP/IP (Ethernet) and RS-485 (ASCII/Modbus RTU), enabling seamless integration with diverse industrial systems. This flexibility allows it to connect to modern SCADA systems via Ethernet while communicating with legacy PLCs or data loggers through RS-485—eliminating the need for additional protocol converters.

Centralized data aggregation: As the primary interface between rack modules and external systems, the 3500/05-01-01-00-00-00 consolidates data from multiple sources: vibration signals from the 3500/33-01-00, conditioned measurements from the 3500/42M 140734-02, and raw inputs from the 330851-02-000-060-10-00-00 transducer. This aggregation provides a unified view of machinery health, simplifying analysis and reducing network traffic.

Real-time data transmission: With a 100 Mbps Ethernet port, the 3500/05-01-01-00-00-00 delivers high-speed data transfer, ensuring critical alarms (e.g., excessive vibration detected by the 330851-02-000-060-10-00-00) reach operators in milliseconds. This low-latency communication is essential for time-sensitive applications like turbine overspeed protection, where delayed alerts could lead to equipment failure.

Rugged reliability: Built to withstand extreme temperatures (-40°C to +70°C) and high humidity, the 3500/05-01-01-00-00-00 maintains communication integrity in harsh environments. Its robust construction includes surge-protected Ethernet ports and isolated RS-485 circuits, preventing damage from electrical noise or transient voltage spikes common in industrial settings.

Typical application scenarios

In a combined-cycle power plant, the 3500/05-01-01-00-00-00 serves as the communication hub for a 3500 series rack monitoring a gas turbine. It collects vibration data from the 3500/33-01-00 (processed from the 330851-02-000-060-10-00-00 transducer) and transmits it via Ethernet to the plant’s DCS using Modbus TCP/IP. Simultaneously, it sends critical alarms to a legacy annunciator panel via RS-485, ensuring both modern and traditional systems remain informed. During a turbine startup, real-time data from the 3500/05-01-01-00-00-00 allows operators to monitor vibration trends and adjust procedures to avoid resonance.

At an offshore oil platform, the 3500/05-01-01-00-00-00 connects a 3500 rack monitoring a centrifugal compressor to the platform’s safety system. It receives pressure and vibration data from the 3500/42M 140734-02 (fed by the 330851-02-000-060-10-00-00) and transmits it via Ethernet to 170180-01-00 software for analysis. When the 3500/33-01-00 detects dangerous vibration levels, the 3500/05-01-01-00-00-00 triggers a shutdown command via RS-485 to the compressor’s PLC, preventing catastrophic failure in the harsh marine environment.

In a chemical plant’s reactor complex, the 3500/05-01-01-00-00-00 integrates with multiple 3500 racks to monitor agitator motors. It aggregates data from 330851-02-000-060-10-00-00 transducers (measuring shaft displacement) and sends it to a central SCADA system via Ethernet. The RS-485 port connects to a local HMI, allowing on-site operators to view real-time status without accessing the main network. This dual connectivity ensures redundancy—critical for maintaining visibility during network outages.

BENTLY 3500/05-01-01-00-00-00

Related model recommendations

330851-02-000-060-10-00-00: Proximity transducer whose data is transmitted through the 3500/05-01-01-00-00-00 after processing by upstream modules.

3500/15 127610-01: Redundant power supply that provides stable 24V DC to the 3500/05-01-01-00-00-00.

3500/33-01-00: Vibration monitoring module that sends alarm data to external systems via the 3500/05-01-01-00-00-00.

3500/42M 140734-02: Signal conditioner whose processed measurements are aggregated by the 3500/05-01-01-00-00-00.

170180-01-00: Software that configures the 3500/05-01-01-00-00-00 and receives data for analysis.

3500/62: Digital I/O module whose status is communicated to external systems via the 3500/05-01-01-00-00-00.

3500/92: Advanced communication gateway that extends the 3500/05-01-01-00-00-00’s capabilities for large-scale networks.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the 3500/05-01-01-00-00-00, power off the 3500 series rack (via the 3500/15 127610-01 supply). Mount the module in a single rack slot, securing it with screws torqued to 0.6 Nm. Connect the Ethernet port to the plant network using shielded Cat5e cable, ensuring proper grounding. For RS-485 connections, use twisted-pair cable with a shield (grounded at one end) to minimize noise. Configure IP settings via 170180-01-00 software to match the network infrastructure.

Maintenance suggestions: Inspect the 3500/05-01-01-00-00-00 quarterly for loose Ethernet/RS-485 connections or corrosion on terminals. Clean connectors with a dry cloth if needed. Verify communication links monthly by checking data flow to 170180-01-00 software and downstream systems. Test redundancy (if paired with a second module) by disconnecting the primary unit and confirming failover. Update firmware annually via Ethernet to ensure compatibility with the latest 3500 series modules, such as the 3500/42M 140734-02. If communication failures occur, check cable integrity and network settings before replacing the module.

Service and guarantee commitment

The 3500/05-01-01-00-00-00 is backed by a 18-month warranty covering manufacturing defects, including communication failures, port malfunctions, or backplane connectivity issues. During this period, Bently Nevada provides free repair or replacement of defective units, along with technical support for integrating with the 330851-02-000-060-10-00-00 and other 3500 series components.

Our global service team offers 24/7 assistance for troubleshooting communication issues, with remote diagnostics available via Ethernet to verify protocol settings and data flow. Extended warranty options (up to 3 years) include annual performance testing and priority firmware updates. Built on Bently Nevada’s expertise in industrial communication, the 3500/05-01-01-00-00-00 is guaranteed to deliver reliable data transmission, ensuring critical machinery monitoring systems remain connected and responsive.