Description

Technical Specifications Table

| Parameter | Specification |

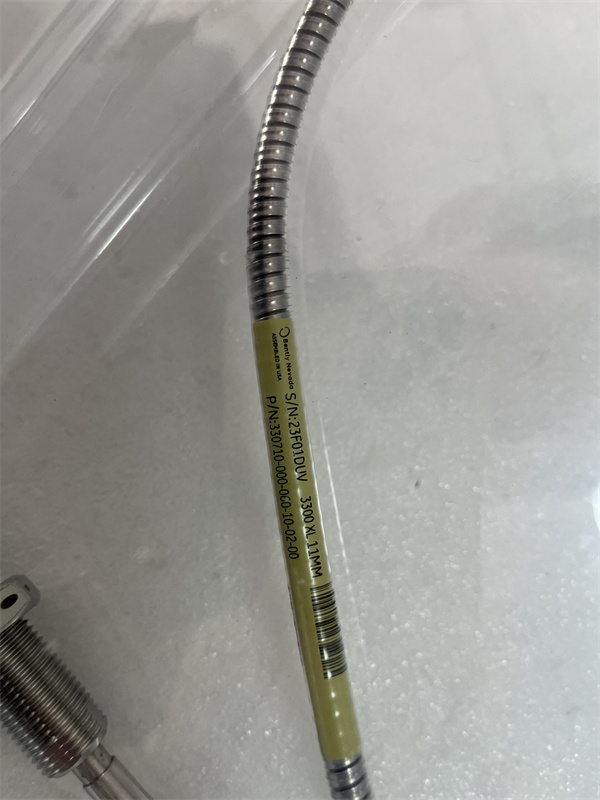

| Model Number | Bently Nevada 330710-000-60-10-02-00 |

| Manufacturer | Bently Nevada (Baker Hughes) |

| Product Type | Proximity Transducer System |

| Measurement Range | 0.08 to 0.236 in (2 to 6 mm) |

| Output Signal | -2 to -18 VDC |

| Frequency Response | 0 to 10 kHz |

| Temperature Range | -40°C to +120°C (-40°F to +248°F) |

| Power Requirement | 18-30 VDC, 10 mA typical |

| Probe Diameter | 8 mm |

| Cable Length | 6 m (19.7 ft) |

| Sensitivity | 200 mV/mil (7.87 V/mm) |

| Environmental Rating | IP67 |

| Compliance Standards | API 670, ISO 10816 |

| Connector Type | Integral MIL-C-5015 |

BENTLY 330710-000-60-10-02-00

Product Overview

The Bently Nevada 330710-000-60-10-02-00 is a complete proximity transducer system designed for critical machinery monitoring applications. This high-precision system provides accurate measurement of shaft vibration and position in rotating equipment, forming an essential component of predictive maintenance programs.

Featuring a 6-meter cable length, this configuration is particularly suited for installations requiring extended reach between the probe and monitoring equipment. The system’s robust construction and wide operating temperature range ensure reliable performance in demanding industrial environments.

Key Features and Benefits

Precision Measurement Technology:

High-resolution displacement measurement

Excellent linearity (±1% of full scale)

Wide frequency response for dynamic motion capture

Stable output across temperature variations

Durable System Design:

316 stainless steel probe housing

High-temperature rated cable (up to 120°C continuous)

IP67 environmental protection

Vibration-resistant construction (20 g capability)

Installation Advantages:

Extended 6-meter cable for flexible routing

MIL-C-5015 connector for secure mating

Pre-calibrated for plug-and-play installation

Compatible with Bently Nevada 3500 series monitors

Industrial Applications

Power Generation:

Turbine shaft vibration monitoring

Generator bearing protection

Auxiliary pump monitoring

Oil & Gas:

Compressor train protection

Pump vibration measurement

Gas turbine monitoring

Heavy Industry:

Large motor vibration analysis

Gearbox condition monitoring

Rolling mill equipment protection

Compatible Monitoring Systems

Bently Nevada 3500/42: Radial Vibration Monitor

Bently Nevada 3500/40: Proximitor® Monitor

Bently Nevada System 1®: Condition monitoring software

Bently Nevada 3500/92: Communication Gateway

Bently Nevada 3500/15: Power Supply Module

BENTLY 330710-000-60-10-02-00

Installation and Maintenance

Installation Requirements:

Proper grounding of all system components

Recommended gap voltage setting: -10 VDC ± 0.5 V

Minimum bend radius of 50 mm for cables

Use of anti-rotation devices on probes

Maintenance Schedule:

Quarterly gap voltage verification

Annual comprehensive system check

Biannual cable integrity inspection

Immediate replacement if physical damage observed

Warranty and Support

Coverage:

24-month standard warranty

Global technical support network

Application engineering assistance

Comprehensive documentation

Calibration services

The Bently Nevada 330710-000-60-10-02-00 system is backed by Bently Nevada’s extensive experience in machinery protection systems, ensuring reliable performance in critical monitoring applications.