Description

Technical Specifications Table

| Parameter | Specification |

| Model Number | Bently Nevada 330180-51-00 |

| Manufacturer | Bently Nevada (Baker Hughes) |

| Product Type | Proximity Transducer Extension Cable |

| Length | 15 feet (4.57 meters) |

| Connector Type | Integral MIL-C-5015 connector |

| Cable Type | Double-shielded coaxial |

| Temperature Range | -40°C to +120°C (-40°F to +248°F) |

| Insulation Material | High-temperature PTFE |

| Outer Jacket | Abrasion-resistant PVC |

| Shielding Effectiveness | >90 dB EMI/RFI protection |

| Voltage Rating | 300V RMS |

| Impedance | 50 Ohms nominal |

| Compatibility | All Bently Nevada 3300 series proximity probes |

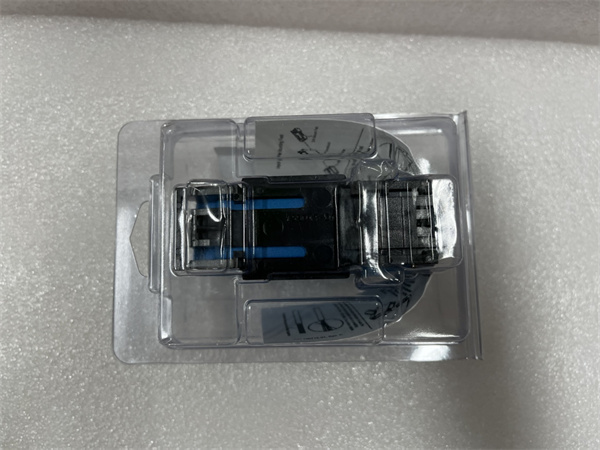

BENTLY 330180-51-00

Product Overview

The Bently Nevada 330180-51-00 is a premium-quality extension cable designed specifically for use with Bently Nevada’s 3300 series proximity transducer systems. This essential component ensures reliable signal transmission between proximity probes and monitoring equipment in critical machinery protection applications.Engineered to maintain signal integrity in electrically noisy industrial environments, the 330180-51-00 features robust construction with double-shielded coaxial design and high-temperature resistant materials. The cable’s 15-foot length provides installation flexibility while minimizing signal degradation, making it ideal for various machine monitoring configurations.

Key Features and Benefits

Superior Signal Integrity:

Double-shielded construction minimizes electromagnetic interference

Precision 50-ohm impedance matching maintains signal quality

Low capacitance design preserves high-frequency response

Gold-plated contacts ensure optimal conductivity

Durability and Reliability:

Abrasion-resistant PVC outer jacket withstands harsh environments

PTFE insulation maintains performance at elevated temperatures

Strain relief features prevent connection failures

Moisture-resistant design (non-hygroscopic materials)

Installation Advantages:

Standard 15-foot length suits most applications

Integral MIL-C-5015 connector ensures secure mating

Flexible cable routing in tight spaces

Color-coded for easy identification

Typical Applications

The Bently Nevada 330180-51-00 extension cable is used in conjunction with proximity transducer systems for:

Turbine Supervisory Systems: Steam and gas turbine vibration monitoring

Compressor Trains: Radial and axial position measurement

Large Motors and Generators: Bearing vibration monitoring

Pump Systems: Critical pump vibration analysis

Paper Machine Rolls: Vibration and eccentricity monitoring

BENTLY 330180-51-00

Compatible Products

Bently Nevada 3300 XL 8mm Proximity Probes: Primary sensor connection

Bently Nevada 3300 Proximitor® Seismic Transducers: Vibration monitoring systems

Bently Nevada 3500 Monitoring System: Machinery protection system integration

Bently Nevada 330130-040-00-00: Alternative 10-foot extension cable

Bently Nevada 330180-50-00: 20-foot extension cable option

Installation and Maintenance Guidelines

Installation Best Practices:

Route cables away from high-voltage sources (>24 inches separation)

Maintain minimum bend radius of 2 inches (50 mm)

Use cable clamps every 18 inches for proper support

Ensure connectors are fully seated and locked

Verify proper grounding of shield at monitor end only

Maintenance Recommendations:

Annual inspection for jacket integrity

Periodic verification of connector tightness

Immediate replacement if shielding is compromised

Clean connectors during routine maintenance

Test cable continuity if signal issues occur

Warranty and Support

Bently Nevada provides:

24-month standard warranty against defects

Global technical support network

Cable testing and certification services

Custom length options available

Cross-reference assistance for legacy systems

The 330180-51-00 is backed by Bently Nevada’s extensive experience in machinery protection systems, ensuring reliable performance in critical monitoring applications.

This technical product description provides comprehensive information about the Bently Nevada 330180-51-00 extension cable, highlighting its technical specifications, features, and proper usage in industrial monitoring systems. The format is optimized for both maintenance technicians and procurement specialists in industries requiring reliable machinery condition monitoring solutions.