Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | Bently Nevada 330104-11-25-10-02-00 |

| Manufacturer | Bently Nevada (Baker Hughes) |

| Product Category | Proximity Probe Assembly |

| Probe Diameter | 11 mm |

| Measurement Range | 0.25 to 2.3 mm (10 to 90 mils) |

| Sensitivity | 7.87 V/mm (200 mV/mil) |

| Temperature Range | -40°C to +177°C |

| Cable Length | 10 meters |

| Connector Type | Military-style threaded |

| Tip Material | Inconel 600 |

| Housing Material | 316 Stainless Steel |

| Certifications | ATEX, IECEx, API 670 |

BENTLY 330104-11-25-10-02-00

Product Introduction

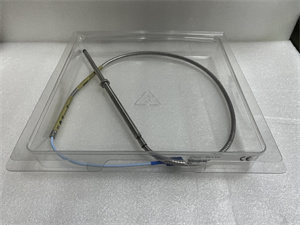

The Bently Nevada 330104-11-25-10-02-00 is a premium 11mm proximity probe assembly designed for critical machinery monitoring in demanding industrial applications. As part of Bently Nevada’s 3300 XL series, this complete transducer system provides precise measurement of shaft vibration, position, and eccentricity in turbines, compressors, and other high-speed rotating equipment.

Engineered for reliability, the assembly includes a high-temperature rated probe, 10-meter integral cable, and military-style connector for secure signal transmission. The Inconel 600 tip material provides exceptional wear resistance in abrasive environments, while the 316 stainless steel housing ensures long-term performance in corrosive conditions.

Core Advantages and Technical Highlights

Extended range measurement:

The Bently Nevada 330104-11-25-10-02-00 offers an expanded 2.3mm measurement range compared to standard probes, making it ideal for applications with large shaft movements. The 7.87 V/mm sensitivity maintains precision across the full range, with ±1% linearity for trustworthy data.

High-temperature capability:

With a -40°C to +177°C operating range, this probe assembly performs reliably in extreme environments like gas turbine exhaust sections or high-temperature steam applications. The Inconel 600 tip resists oxidation and maintains calibration stability at elevated temperatures.

Robust mechanical design:

The 11mm diameter probe body provides enhanced durability in high-vibration applications. The 316 stainless steel construction resists corrosion in offshore and chemical plant environments. The 10-meter integral cable reduces connection points that could compromise signal integrity.

Comprehensive system integration:

The assembly includes a pre-calibrated extension cable and military-style connector for direct compatibility with Bently Nevada 3300 XL monitoring systems. The API 670 compliance ensures suitability for critical refinery and petrochemical applications.

Typical Application Scenarios

Gas turbine monitoring:

The Bently Nevada 330104-11-25-10-02-00 is ideal for measuring turbine shaft eccentricity during startup, where large thermal growth occurs. Its high-temperature rating allows installation near hot gas paths.

Hydrogen compressors:

In refinery service, the probe’s Inconel tip resists hydrogen embrittlement while monitoring shaft position in high-pressure compressors. The 10m cable accommodates large machine layouts.

Paper mill machinery:

The 316 stainless construction withstands corrosive pulp chemicals while monitoring roll grinding equipment. The extended measurement range accommodates large roll movements.

Offshore platform pumps:

The ATEX-certified assembly provides vibration monitoring in hazardous areas. The integral cable survives constant platform vibrations and salt spray exposure.

BENTLY 330104-11-25-10-02-00

Related Model Recommendations

Bently Nevada 330104-08-05-10-02-00: 8mm probe with 5m cable

Bently Nevada 330104-11-05-05-02-00: 11mm probe with 5m cable

Bently Nevada 330130-040-00-00: Extension cable assembly

Bently Nevada 3300/20: Proximitor power supply

Bently Nevada 3300/16: Monitor module

Bently Nevada 330901-00-05-10-02-00: Replacement probe tip kit

Installation and Commissioning

Installation preparation:

Verify proper gap voltage (typically -10V DC) before installation. Ensure the target surface is clean, smooth, and free from coatings. Prepare the mounting location with appropriate threaded inserts for the 11mm probe body.

Commissioning steps:

Install probe at recommended angle (90° to shaft)

Set initial gap using feeler gauges

Verify system calibration

Test dynamic response with shaft rotation

Document baseline readings

Confirm alarm thresholds in monitoring system

Maintenance recommendations:

Annual calibration verification

Quarterly inspection of probe tip condition

Regular cable integrity checks

Monitoring of trend data for sensitivity changes

Replacement per OEM recommended intervals

Service and Guarantee Commitment

Baker Hughes provides:

36-month warranty on materials and workmanship

Global technical support network

NIST-traceable calibration services

On-site commissioning assistance

Repair and refurbishment programs

The Bently Nevada 330104-11-25-10-02-00 is backed by Baker Hughes’ Machine Health Center with 24/7 diagnostic support. All units include complete documentation including calibration certificates and hazardous area certifications where applicable.