Description

Technical Specifications Table

| Parameter | Specification |

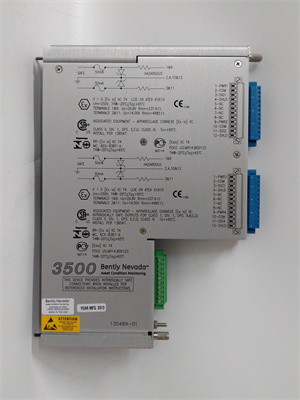

| Model Number | Bently Nevada 135489-01 |

| Manufacturer | Bently Nevada (Baker Hughes) |

| Product Type | Industrial IEPE Accelerometer |

| Sensitivity | 100 mV/g (±5%) |

| Measurement Range | ±50 g peak |

| Frequency Response | 0.5 Hz to 10 kHz (±3 dB) |

| Resonant Frequency | >28 kHz |

| Output Signal | 2-10 mA constant current |

| Power Supply | 18-30 VDC, 2-20 mA |

| Housing Material | Titanium alloy |

| Mounting | M6 threaded stud |

| Environmental Rating | IP68 (submersible to 3m) |

| Operating Temperature | -55°C to +125°C (-67°F to +257°F) |

| Shock Resistance | 500 g, 1 ms |

| Compliance Standards | API 670, ISO 10816, ATEX/IECEx (optional) |

BENTLY 135489-01

Product Overview

The Bently Nevada 135489-01 represents a high-performance industrial accelerometer designed for extreme-condition machinery monitoring. This rugged sensor combines Integrated Electronics Piezo-Electric (IEPE) technology with military-grade construction for reliable vibration measurement in the most demanding industrial environments.

As part of Bently Nevada’s premium monitoring solutions, the 135489-01 features a titanium alloy housing and advanced signal conditioning electronics that maintain accuracy in high-electromagnetic interference areas. Its extended temperature range and submersible design make it particularly suitable for offshore, marine, and heavy industrial applications.

Key Features and Benefits

Precision Measurement:

Ultra-wide frequency response (0.5 Hz to 10 kHz)

High sensitivity with low noise floor

Excellent phase response (±1° from 10 Hz to 5 kHz)

Dual-range output (field-selectable 4-20mA or 2-10V)

Extreme Environment Design:

Titanium alloy housing for corrosion resistance

Hermetic glass-to-metal seals

Submersible to 3 meters (IP68)

Explosion-proof versions available

Smart Monitoring Capabilities:

Built-in diagnostics (sensor health monitoring)

Plug-and-play auto-configuration

Digital identification (IEC 61987 compliant)

Predictive maintenance trending outputs

Industrial Applications

Oil & Gas:

Subsea pump monitoring

Offshore platform equipment

LNG compressor protection

Power Generation:

Nuclear plant machinery

Hydroelectric turbine monitoring

Cooling system vibration analysis

Heavy Industry:

Mining equipment monitoring

Steel mill rolling equipment

Paper machine dryer sections

Installation Guidelines

Mechanical Installation:

Surface preparation (Ra < 1.6 μm recommended)

Apply anti-seize compound to threads

Torque to 7 Nm ±10% using calibrated wrench

Verify proper grounding path

Electrical Connection:

Use double-shielded cable (Belden 8761 or equivalent)

Ground shield at monitor end only

Maintain minimum 30 cm separation from power cables

Verify loop impedance (<600Ω)

Commissioning:

Perform baseline measurement

Verify frequency response

Set alarm thresholds

Record as-left calibration data

BENTLY 135489-01

Maintenance Procedures

Preventive Maintenance:

Quarterly visual inspections

Annual calibration verification

Biannual cable integrity tests

5-year comprehensive overhaul

Diagnostic Features:

Built-in self-test capability

Degradation trend monitoring

Fault code output

Predictive replacement indicators

Troubleshooting:

LED status indicator (green/red)

Output signal validation

Vibration signature analysis

Comparative channel monitoring

Warranty and Support

Premium Coverage:

36-month extended warranty

Includes calibration drift

On-site replacement service

Priority technical support

Global Support Network:

24/7 emergency response

Regional repair centers

Application engineering

Training programs

Documentation Package:

SIL compliance documentation

Hazardous area certifications

Material traceability records

Installation validation forms

The Bently Nevada 135489-01 sets a new standard for industrial vibration monitoring, combining advanced sensing technology with extreme environment durability for mission-critical machinery protection applications.