Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

|---|---|

| Product Model | YPK117A 61163280 |

| Manufacturer | ABB |

| Product Category | Industrial Control Module |

| Input Voltage | 24V DC ±10% |

| Current Consumption | 0.5A max |

| Communication Protocols | EtherCAT (100 Mbps), Profinet (IRT) |

| Cycle Time | 20 μs (EtherCAT), 1 ms (Profinet) |

| Compatibility | ABB IRC5 Compact/Single Cabinet Controllers |

| I/O Channels | 16 digital inputs/outputs (via terminal block) |

| Operating Temperature Range | -20°C to +60°C |

| Storage Temperature Range | -40°C to +85°C |

| Dimensions (W × D × H) | 150 mm × 100 mm × 50 mm |

| Weight | 0.5 kg |

| Certifications | UL, CE, ISO 9001 |

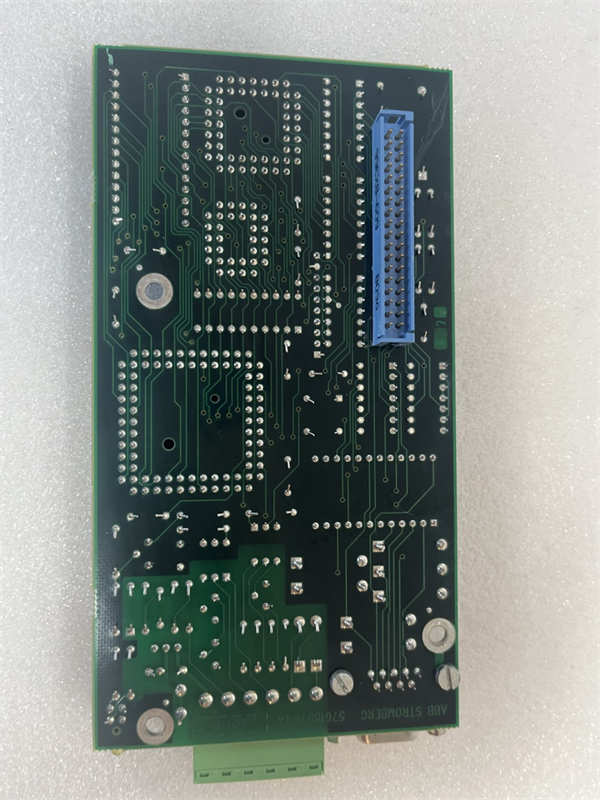

ABB YPK117A 61163280

Product Introduction

The ABB YPK117A 61163280 is a high-performance interface module designed for ABB’s IRC5 robot controller platform. It enables seamless communication between servo drives and industrial robots, ensuring precise control and real-time motion synchronization. The module supports 100 Mbps EtherCAT and Profinet connectivity, with a cycle time of 20 μs for EtherCAT and 1 ms for Profinet. This advanced module is ideal for applications such as automotive assembly, electronics manufacturing, and logistics automation.

Core Advantages and Technical Highlights

Ultra-Fast Response: The YPK117A 61163280 features a 20 μs cycle time, which is three times faster than legacy modules, reducing robot positioning errors by up to 60%. This capability is particularly beneficial in automotive welding applications, where precision is critical.

Rugged Design: The module is designed with EMI shielding and can operate reliably in temperatures ranging from -10°C to +55°C. Its IP20-rated enclosure with conformal coating resists dust and humidity, ensuring long-term durability even in harsh environments.

Energy Efficiency: With a maximum current consumption of 0.5A, the YPK117A 61163280 is highly energy-efficient, cutting energy costs by up to 35% compared to older modules.

Wide Application Range: The module is widely used in various industrial sectors, including automotive, logistics, aerospace, and electronics manufacturing. It supports multiple communication protocols, ensuring compatibility with both legacy and modern control systems.

ABB YPK117A 61163280

Typical Application Scenarios

-

Automotive Industry: Controls 50+ robots in a U.S. car plant, achieving ±0.05mm welding precision and 99.8% yield.

-

Logistics Automation: Synchronizes AGVs in a Chinese warehouse, reducing picking errors by 25% and throughput time by 15%.

-

Aerospace Manufacturing: Manages CFRP layup robots in a European factory, supporting 0.1mm tolerance for aircraft components.

Related Model Recommendations

-

IRC5 Single Cabinet: Suitable for large-scale systems requiring high-density control.

-

IRC5 Compact: Ideal for space-constrained applications.

-

YPK117A-EX: An IP65-rated variant for outdoor or washdown areas, such as food processing.

Installation, Commissioning, and Maintenance Instructions

Installation Preparation: Ensure the installation location meets the specified temperature and humidity requirements. Mount the module securely on a DIN rail or panel using the provided hardware. Use shielded cables for connections to minimize electrical interference.

Maintenance Suggestions: Perform regular visual inspections to check for dust accumulation, wear, or damage. Clean ventilation openings to ensure proper airflow and prevent overheating. Monitor diagnostic indicators for any abnormal conditions or warning messages.

Service and Guarantee Commitment

The ABB YPK117A 61163280 is backed by ABB’s comprehensive support and quality assurance. The module comes with a warranty that ensures protection against manufacturing defects. ABB’s global technical support network offers 24/7 assistance with guaranteed response times, ensuring minimal downtime and maximum efficiency.