Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

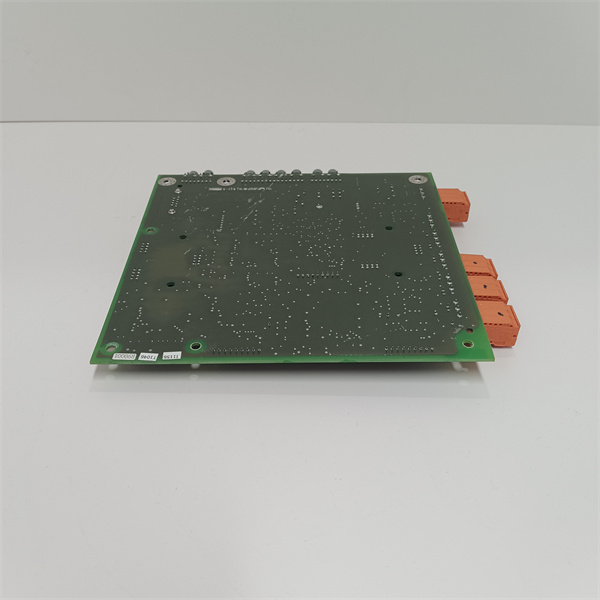

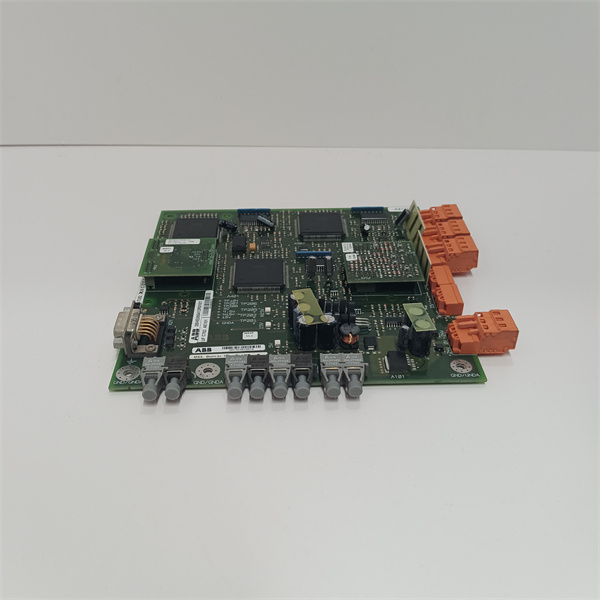

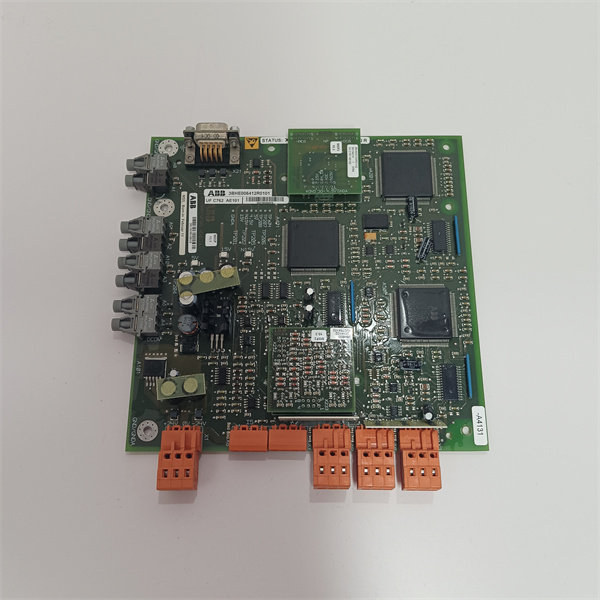

| Product Model | ABB UFC762AE101 3BHE006412R0101 |

| Manufacturer | ABB |

| Product Category | High Integrity Controller Module (AC 800M HI) |

| Processor Architecture | Triple Modular Redundant (TMR) PowerPC |

| Safety Certification | SIL 3 (IEC 61508), AK6 (DIN V 19250) |

| Memory | 64 MB SDRAM / 32 MB Flash |

| Backplane Interface | HI Bus (TMR Synchronization) |

| I/O Handling Capacity | ≤32,000 points per controller |

| Communication Ports | 2 x Ethernet (100BASE-TX), 1 x RS-232 Service |

| Redundancy Support | Controller, I/O, and Network Hot Swap |

| Switchover Time | <100 ms (process interruption-free) |

| Operating Temperature | –40°C to +70°C (–40°F to +158°F) |

| Power Supply | 24 VDC (±10%), 15 W typical |

| Vibration Resistance | 5 g (5–150 Hz) per IEC 60068-2-6 |

| Certifications | cFMus, ATEX Zone 2, DNV GL, IECEx |

ABB UFC762AE101 3BHE006412R0101

Product Introduction

The ABB UFC762AE101 3BHE006412R0101 is a mission-critical Triple Modular Redundant (TMR) controller module for ABB’s AC 800M High Integrity (HI) platform, designed for Safety Instrumented Systems (SIS) requiring SIL 3 certification. As the central processing unit in ABB’s 800xA High Integrity solution, this module executes safety logic with hardware fault tolerance through parallel processing across three independent channels. The UFC762AE101 continuously compares results, enabling automatic fault masking and seamless switchover during component failures.

Engineered for extreme reliability in hazardous environments, this controller integrates with ABB’s HI-specific I/O modules (e.g., SD826, SD838) via a fault-tolerant backplane. It supports deterministic execution of safety functions—such as emergency shutdown (ESD) and fire & gas (F&G) systems—with sub-100 ms response times. The ABB UFC762AE101 3BHE006412R0101 delivers the zero-compromise integrity needed for oil/gas, nuclear, and chemical processes where undetected system failures could have catastrophic consequences.

Core Advantages and Technical Highlights

Ultra-High Availability TMR Architecture: Three independent processors execute identical logic simultaneously. A dedicated voter circuit compares outputs in real-time, masking single faults without process interruption. Achieves >99.9999% availability (MTBF > 75 years).

Deterministic Safety Performance: Executes SIL 3 logic blocks in ≤10 ms scan cycles. Hardware-assisted “Watchdog Processor” monitors execution timing, triggering fail-safe state on divergence.

Seamless Fault Recovery: Online module replacement supported for controllers, I/O, and networks. Automatic database synchronization during switchover (<100 ms). “Hot Repair” capability allows component replacement without shutdown.

Advanced Cybersecurity: Hardware-enforced secure boot with cryptographic signature verification. Supports role-based access control (RBAC) and audit trails compliant with ISA/IEC 62443.

Extreme Environment Resilience: Operates at –40°C with conformal-coated PCBs resisting humidity and corrosive chemicals (ISA-71.04 G4). ATEX Zone 2/22 certification for hazardous areas.

Unified Engineering: Programmed via ABB’s Control Builder Safe using certified function blocks (IEC 61131-3). Full integration with 800xA DCS for unified operator views.

Typical Application Scenarios

Offshore Oil & Gas ESD: Implements SIL 3 shutdown logic for subsea valves and compressor anti-surge systems. The UFC762AE101’s TMR architecture prevents spurious trips while ensuring fail-safe response to wellhead pressure excursions.

Nuclear Reactor Protection: Controls boron injection and control rod drives with NRC-approved fault tolerance. Radiation-hardened design withstands LOCA (Loss-of-Coolant Accident) conditions.

Chemical Plant Burner Management: Manages furnace purge sequences and flame detection with AK6-certified logic. Hardware voting overrides sensor failures during high-risk startups.

LNG Cryogenic Safety: Monitors tank overpressure and leak detection systems. Operates reliably at –40°C near liquefaction trains.

Hydrogen Production Electrolyzers: Executes emergency de-energization when gas concentration exceeds LEL. ATEX-compliant design prevents ignition in Zone 2 areas.

ABB UFC762AE101 3BHE006412R0101

Related Model Recommendations

ABB UF723A 3BHE004573R0101: HI Power Supply Module (redundant 24VDC input for UFC762AE101).

ABB SD826 3BSE020510R1: SIL 3 Digital Input Module (supports <1 ms response).

ABB SD838 3BSE018741R1: Analog Output Module with HART for final elements.

ABB CI857K01 3BSE018104R1: PROFIBUS DP-V1 Interface for safety networks.

ABB TU847 3BSE022464R1: HI Termination Unit for redundant I/O wiring.

ABB XU801 3BSE020588R1: HI Expansion Unit for >3,000 I/O points.

ABB PM866 3BSE050199R1: Standard AC 800M controller for non-SIL basic process control.

ABB S800 I/O HI Series: SIL 3-certified modules (e.g., AI825, DO820).

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Mount UFC762AE101 in HI-certified rack (e.g., RU813) using ESD wrist straps. Verify ambient temperature ≤60°C. Isolate 24VDC power with Class 2 transformers. Use ABB-recommended DIN rails (EN 50022). Maintain 50 mm clearance above/below for cooling. Configure TMR synchronization cables with exact equal lengths (±5 mm).

Maintenance Suggestions:

Monthly: Validate voter alignment via Control Builder Safe diagnostics. Check synchronization LED status (green steady).

Annually: Perform forced fault injection test (channel removal) during planned shutdowns. Verify switchover time <100 ms.

Cybersecurity: Apply firmware patches within 30 days of ABB Security Advisory releases.

Replacement: Always swap with 3BHE006412R0101 hardware revision. Reload application from secure golden copy.

Critical: Never mix firmware versions across TMR channels.

Service and Guarantee Commitment

ABB provides a 5-year warranty for the UFC762AE101 3BHE006412R0101, including SIL 3 recertification support. Global coverage includes:

24/7 Critical Support Hub with TMR specialists

On-site safety validation per IEC 61511

Lifetime firmware/security updates

Spares availability guarantee until 2040

SIL compliance audits and “Proof Testing” packages

Extended service agreements feature:

≤4-hour emergency response for offshore facilities

Predictive health analytics via ABB Ability™

Cybersecurity penetration testing

Migration services from legacy Procontrol-P13/Satt systems

Note: SIL 3 certification requires full system validation by certified engineers.