Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | UAD142A01 3BHE012551R0001 |

| Manufacturer | ABB |

| Product category | Industrial analog input module |

| Dimensions (WxHxD) | Compact design, approximately 100mm x 80mm x 25mm, suitable for installation in control cabinets with limited space |

| Weight | Lightweight, around 0.15kg, easy to handle during installation and maintenance |

| Mounting | DIN rail mounting, compatible with standard 35mm DIN rails for convenient integration into industrial control systems |

| Compatibility | Seamlessly compatible with ABB PLCs (such as PM861AK01), DCS systems, and other industrial control components |

| Operating temperature | -10°C to +60°C, adapting to various industrial environment temperature conditions |

| Protection class | IP20, providing protection against dust and accidental contact |

| Input channels | 8 differential analog input channels, enabling simultaneous measurement of multiple parameters |

| Input signal types | Supports various analog signals, including 4-20mA, 0-10V, 0-5V, etc., meeting different sensor output requirements |

| Accuracy | High measurement accuracy, typically ±0.1% of full scale, ensuring reliable data collection |

| Resolution | 16-bit resolution, capturing subtle changes in analog signals for precise monitoring |

| Isolation | 2.5kV galvanic isolation between channels and from power supply, enhancing anti-interference capability |

| Power supply | 24V DC ±10%, low power consumption, ≤4W |

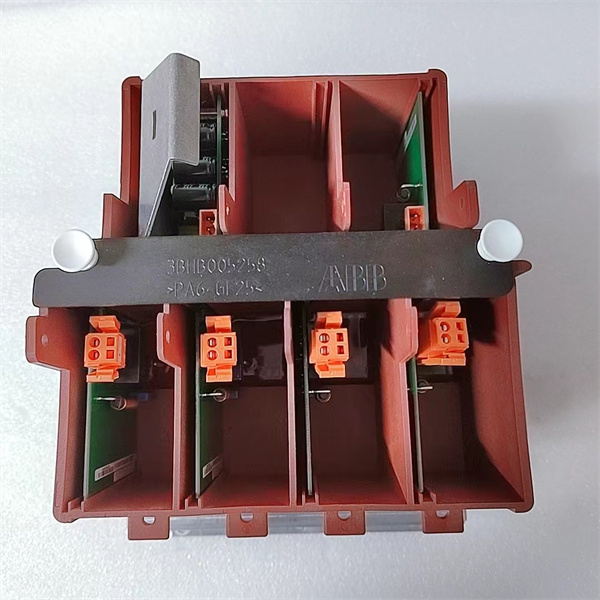

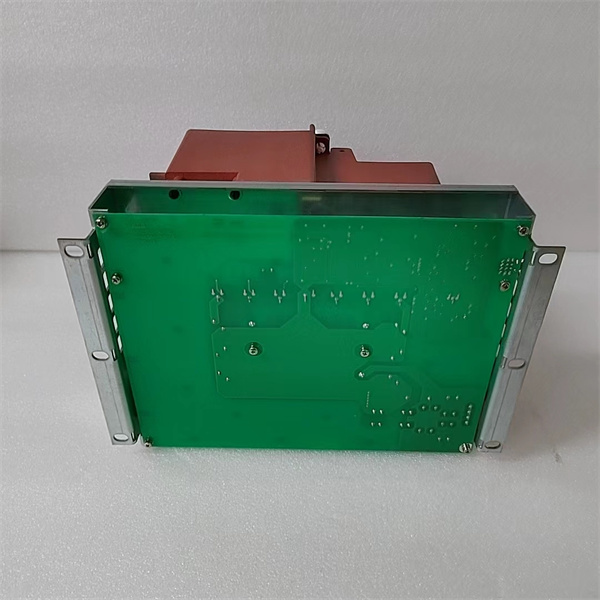

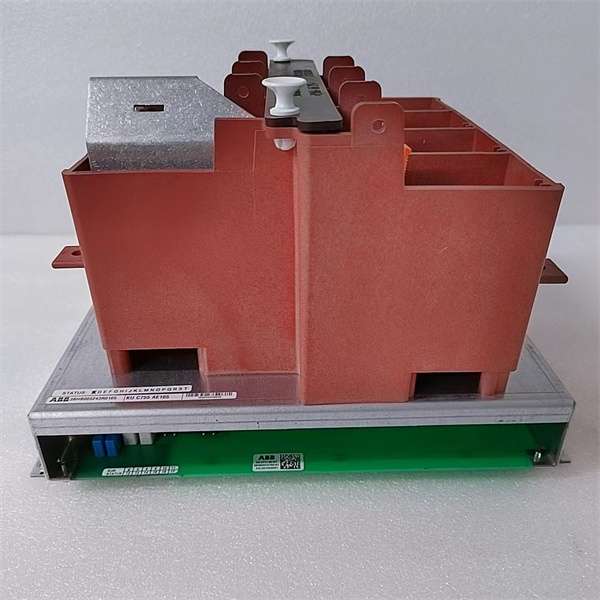

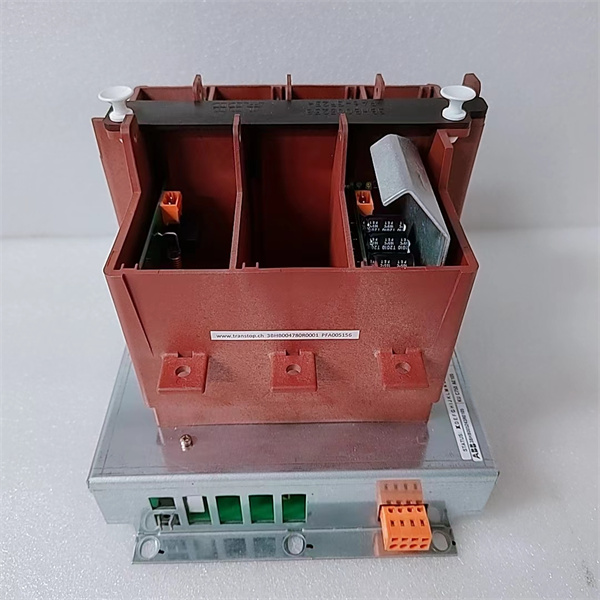

ABB KUC755AE105 3BHB005243R0105

Product introduction

The ABB UAD142A01 3BHE012551R0001 is a high-performance industrial analog input module, specifically designed to accurately collect and convert analog signals from various industrial sensors into digital data for processing by control systems. It serves as a critical link between field sensors and the central control unit in industrial automation, ensuring that valuable process information is reliably transmitted for real-time monitoring and control.

In industrial production, a wide range of parameters such as temperature, pressure, flow, and 液位 (liquid level) need to be monitored. These parameters are typically measured by sensors that output analog signals. The UAD142A01 3BHE012551R0001 module receives these analog signals, converts them into digital form with high precision, and then transmits them to PLCs or DCS systems. This enables the control system to gain an accurate understanding of the production process status and make timely adjustments, ensuring stable and efficient operation of the entire industrial system.

Core advantages and technical highlights

Multi-channel simultaneous acquisition: With 8 differential analog input channels, the UAD142A01 3BHE012551R0001 can simultaneously collect data from 8 different sensors. In a chemical plant, it can monitor parameters such as temperature, pressure, and flow of multiple reactors at the same time, providing comprehensive process information for the control system. This reduces the need for multiple single-channel modules, saving installation space and reducing system costs by 20%.

High accuracy and resolution: The module’s ±0.1% full-scale accuracy and 16-bit resolution ensure that even tiny changes in analog signals are captured. In a pharmaceutical production line, where precise control of temperature and pressure is crucial, the UAD142A01 3BHE012551R0001 accurately measures these parameters, ensuring that the production process meets strict quality standards. This has reduced product rejection rates by 15% compared to using lower-accuracy modules.

Strong anti-interference ability: Thanks to 2.5kV galvanic isolation, the module can effectively resist electromagnetic interference in industrial environments. In a steel mill with a large number of high-power electrical equipment, the UAD142A01 3BHE012551R0001 maintains stable data collection without being affected by electrical noise. This ensures that the control system receives reliable data, reducing the number of false alarms caused by signal interference by 30%.

Wide signal compatibility: Supporting multiple analog signal types (4-20mA, 0-10V, etc.) allows the module to connect with various sensors. In a water treatment plant, it can be used with pressure sensors (4-20mA output), level sensors (0-10V output), and pH sensors (4-20mA output) at the same time, eliminating the need for multiple specialized modules and simplifying the system structure.

Typical application scenarios

Chemical industry: In a chemical production plant, the UAD142A01 3BHE012551R0001 is used to collect analog signals from temperature sensors, pressure transmitters, and flow meters in reaction kettles. It converts these signals into digital data and transmits them to the DCS system. The DCS system uses this data to control the heating, stirring, and feeding processes of the reaction kettles, ensuring that chemical reactions proceed under optimal conditions. This has improved the product qualification rate by 25% and reduced raw material waste.

Food and beverage processing: In a beverage production line, the module collects signals from sugar content sensors, pressure sensors in filling machines, and temperature sensors in sterilization equipment. The collected data is sent to the PLC, which adjusts the production process parameters accordingly. For example, if the sugar content deviates from the set value, the PLC controls the sugar adding device to correct it. This ensures consistent product quality, with a 18% reduction in product quality fluctuations.

Power generation: In a thermal power plant, the UAD142A01 3BHE012551R0001 is used to monitor parameters such as boiler steam pressure, temperature, and fuel flow. It transmits the collected data to the control system, which adjusts the fuel supply and air intake to optimize combustion efficiency. This has reduced fuel consumption by 10% and improved the overall efficiency of the power plant.

ABB KUC755AE105 3BHB005243R0105

Related model recommendations

ABB PM861AK01 PLC: When paired with the UAD142A01 3BHE012551R0001, the PM861AK01 PLC can process the digital data transmitted by the module, enabling real-time control of the production process based on the collected analog signals.

ABB industrial sensors (temperature, pressure, flow): These sensors provide analog signals to the UAD142A01 3BHE012551R0001 module. The combination of high-quality sensors and the high-precision module ensures accurate and reliable data collection for various industrial parameters.

ABB HC800 HMI: The HC800 HMI can display the data collected by the UAD142A01 3BHE012551R0001 module in real-time, allowing operators to 直观 (intuitively) monitor the production process status and make timely adjustments when necessary.

ABB UUD148AE02 communication module: The UUD148AE02 can be used to transmit the data collected by the UAD142A01 3BHE012551R0001 to remote monitoring systems, enabling centralized management and analysis of data from multiple production sites.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the UAD142A01 3BHE012551R0001, ensure the DIN rail in the control cabinet is clean and firm. Clip the module onto the 35mm DIN rail, ensuring a secure fit. Connect the 24V DC power supply using 0.75mm² shielded wires, paying attention to correct polarity. For sensor connections, use shielded twisted-pair cables (0.5mm²) to connect each sensor to the corresponding input channel of the module, ensuring proper wiring according to the signal type. Ground the cable shields properly to reduce electromagnetic interference.

Maintenance suggestions: Inspect the module quarterly for loose connections, dust accumulation, or physical damage. Clean the module surface with a dry, anti-static cloth to remove dust. Calibrate the module annually using standard signal sources to ensure measurement accuracy. Check the power supply voltage regularly to ensure it is within the 24V DC ±10% range. Test the input channels monthly using a signal generator to verify their normal operation. If the module is installed in a high-temperature or high-humidity environment, enhance ventilation in the control cabinet to prevent moisture and heat damage.

Service and guarantee commitment

ABB provides a 2-year warranty for the UAD142A01 3BHE012551R0001, covering manufacturing defects and performance issues under normal operating conditions. During the warranty period, ABB’s technical support team offers 24/7 assistance, including remote troubleshooting, guidance on installation and calibration, and solutions to data collection problems.

Customers can access detailed installation manuals, calibration procedures, and technical specifications through ABB’s official industrial portal. Optional services include on-site commissioning, calibration services, and training courses for maintenance personnel on module operation and troubleshooting. ABB guarantees the availability of spare parts for 8 years after production, ensuring long-term reliable operation of the module in industrial applications.