Description

Key Technical Specifications

- Model Number: ABB YPQ110A

- Manufacturer: ABB Drives Division

- Rated Power: 11kW (15HP) at 400V AC

- Input Voltage: 3-phase 380–480V AC, 50/60Hz

- Output Current: 25A RMS continuous; 50A RMS peak (10-second duration)

- Core Component: ABB proprietary third-generation IGBT (Insulated Gate Bipolar Transistor)

- Efficiency: ≥97% at rated load; ≥95% at 50% load (no-load loss <50W)

- Control Interface: ABB RINT-6611 control unit (mandatory pairing for drive operation)

- Protection Features: Overcurrent, overvoltage (DC bus), undervoltage, overtemperature, short-circuit (phase-to-phase/ground)

- Operating Temperature: -10°C to +40°C (no derating); +40°C to +60°C (linear derating @ 1.67%/°C)

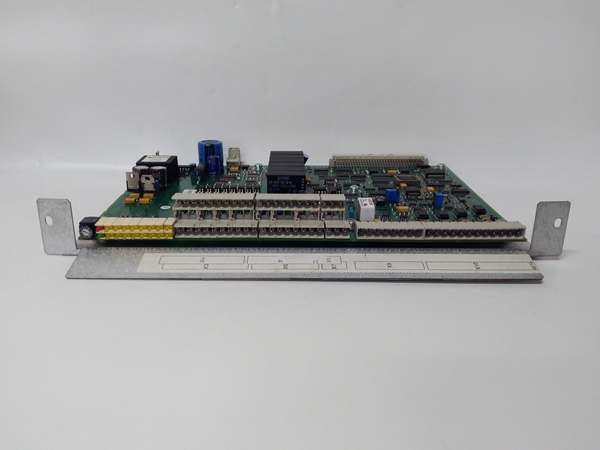

- Physical Dimensions: 260mm × 190mm × 320mm (W×H×D), cabinet-mount with aluminum heat sink

- Certifications: IEC 61800-5-1, CE, UL 61800-5-1, RoHS 2.0, ISO 9001

ABB YPQ110A

Field Application & Problem Solved

In harsh industrial settings—refineries, auto plants, and paper mills—11kW motor drives fail most often due to shoddy power modules. A Texas refinery lost $48,000 in a single shift when a generic module’s IGBTs burned out during a voltage spike, taking down a crude transfer pump and damaging the motor. Legacy modules also struggle with slow protection response (≥100μs) and poor heat dissipation, leading to monthly unplanned downtime averaging 6–8 hours for mid-sized facilities. Worse, non-ABB modules lack integration with control systems, leaving technicians blind to pending failures.

You’ll find this module in ACS880 drive cabinets powering critical equipment: wastewater pumps in Florida’s humid plants, conveyor lines in Michigan auto factories, and CNC machine tools in Ohio metal shops. Its core value is uncompromised reliability in harsh conditions. ABB’s proprietary IGBTs handle 10% voltage swings without derating, and the <20μs fault response time cuts off destructive currents before they reach the motor. A Wisconsin paper mill swapped 12 generic modules for this model and eliminated drive-related downtime entirely—saving $360,000 annually. The efficiency gain (3–5% over legacy units) also trimmed their energy bill by $18,000 per year for 50 drives.

Installation & Maintenance Pitfalls (Expert Tips)

- Surge Protection Is Non-Negotiable: Rookies skip input-side surge suppression, but grid spikes (common during transformer switching) fry IGBTs. Install ABB’s RC snubber (3AXD50000021456) and MOV—this fixed a Pennsylvania steel mill’s issue of 3 module failures per month. Never rely on the module’s internal clamping diodes alone.

- Torque Terminals to 1.8N·m (No Exceptions): Loose terminals cause arcing and overheating. A North Carolina packaging plant used 1.5mm² wire (too small) and hand-tightened terminals—resulting in melted insulation and a 4-hour shutdown. Use 2.5mm² stranded copper with ferrules and a calibrated torque wrench.

- Calibrate After Replacement: Slapping a new module in without calibrating via Drive Composer causes current imbalance. A Michigan CNC shop learned this the hard way: uncalibrated modules led to 0.5mm machining errors and $5,000 in scrap. Run “Power Module Identification” and “Current Loop Calibration” every time.

- Clean Heat Sinks on Environment-Based Cycles: Dust buildup doubles thermal resistance. In dusty cement plants, clean monthly with 0.3MPa compressed air (blow from fan side out). A Missouri plant ignored this—modules hit 78°C and tripped; cleaning dropped temps to 41°C. Replace fans every 3 years (ABB part 3AXD50000045678).

ABB YPQ110A

Technical Deep Dive & Overview

The YPQ110A is the power conversion backbone of ABB’s ACS880 drive system, engineered for precise motor control in harsh industrial environments. It operates in three core stages: first, a 3-phase rectifier converts incoming AC power to DC (filtered by a DC bus capacitor bank); second, ABB’s proprietary IGBTs—switching at up to 16kHz—chop the DC into variable-frequency AC via PWM (pulse-width modulation) signals from the RINT-6611 control unit; third, the output is conditioned to match the motor’s speed and torque requirements.

What sets it apart is the integration of hardware and software protection: Hall-effect current sensors monitor output 100 times per second, triggering IGBT shutdown in 20μs if overcurrent is detected. A surface-mounted NTC thermistor on the IGBT die provides real-time temperature data, initiating fan speed adjustments at 55°C and forced shutdown at 75°C. The module communicates with the control unit via a dedicated CAN bus, logging faults (e.g., overvoltage, undervoltage) with timestamps for rapid troubleshooting. Its conformal-coated PCB resists oil, dust, and chemical splashes, while the aluminum heat sink’s optimized fin design maximizes heat dissipation—critical for 24/7 operation in unconditioned cabinets. This combination of ruggedness and intelligence makes it the go-to for applications where downtime isn’t an option.