Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | YPK117A 61163280 |

| Manufacturer | ABB |

| Product Category | Digital Input Module |

| Series | Advant Controller 800xA (S800 I/O Compatible) |

| Input Channels | 16 channels (Group-isolated) |

| Input Type | Dry Contact / Wet Contact (24 VDC Sourcing) |

| Input Voltage Range | 0-30 VDC (Nominal 24 VDC) |

| Logic “1” Level | +15 to +30 VDC (Typ. +19 V) |

| Logic “0” Level | -3 to +5 VDC |

| Isolation | 500 V AC (Channel Groups) |

| Response Time | ≤ 3 ms |

| Field Connection | Removable screw terminal block |

| Power Consumption | ≤ 1.8 W (24 VDC) |

| Operating Temperature | -25°C to +70°C (-13°F to +158°F) |

| Certifications | CE, UL, cULus, ATEX (Zone 2) |

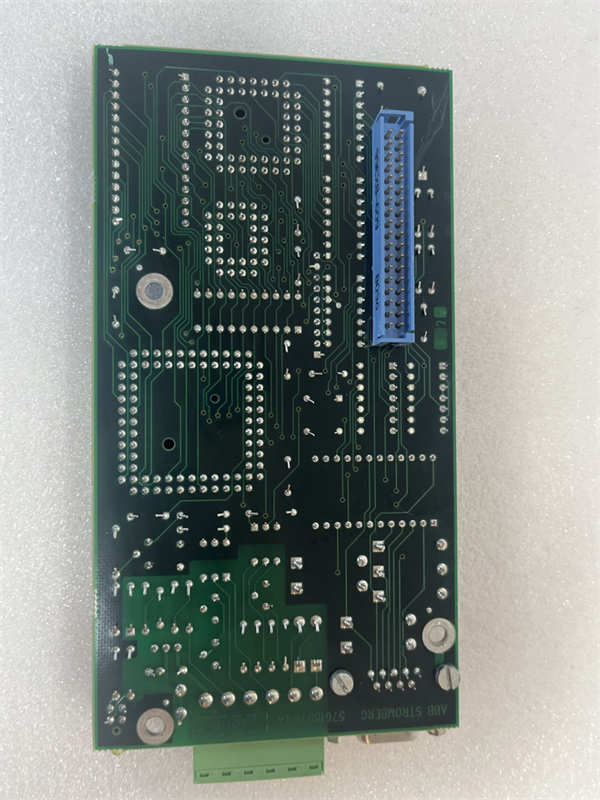

ABB YPK117A 61163280

Product Introduction

The ABB YPK117A 61163280 is a high-density digital input module engineered for integration with ABB’s Advant Controller 800xA and AC 800M systems. As a critical component of the S800 I/O family, this module specializes in converting field-level discrete signals (e.g., switch statuses, relay contacts, or sensor outputs) into reliable digital data for process control and safety systems. The YPK117A operates with 24 VDC field signals and supports both dry contacts (mechanical switches) and wet contacts (sourcing inputs), providing exceptional deployment flexibility.

Designed for rugged industrial environments, the ABB YPK117A 61163280 delivers deterministic performance in applications requiring fast response times and electrical noise immunity. Its technical positioning targets critical monitoring functions in power generation, oil & gas, and manufacturing, where precise state detection of valves, motors, limit switches, and emergency stops is essential. The module integrates natively with ABB’s Control Builder M engineering environment, enabling seamless configuration, diagnostics, and real-time data visualization within the broader automation architecture.

Core Advantages and Technical Highlights

The ABB YPK117A 61163280 excels in demanding applications through these key attributes:

Robust Electrical Design: Featuring 500 V AC group isolation and surge protection, the YPK117A eliminates ground loops and withstands voltage transients common in industrial settings. Its wide input voltage range (0–30 VDC) ensures stable operation despite line fluctuations.

High-Density Channel Configuration: With 16 inputs in a single module slot, the YPK117A optimizes cabinet space and reduces per-channel costs. Channels are grouped (typically 8 per group) with shared isolation, balancing safety and density.

Fast Response & Diagnostics: A ≤3 ms response time enables rapid detection of state changes for time-critical processes. Integrated diagnostics monitor channel health, wire breaks, and field power loss, feeding real-time alerts to the control system.

ATEX Zone 2 Compliance: Certified for hazardous locations, the ABB YPK117A 61163280 operates safely in areas with combustible gases or dust, reducing explosion risks.

Hot-Swap Capability (System Dependent): When used in redundant or hot-swappable S800 I/O racks, the module can be replaced without system shutdown, maximizing uptime.

Backward Compatibility: Fully compatible with legacy Advant OCS and S800 I/O infrastructures, protecting existing investments while enabling phased upgrades.

Typical Application Scenarios

Power Generation: In turbine control rooms, the YPK117A monitors emergency trip signals, cooling pump statuses, and breaker positions. Its fast response ensures immediate shutdown sequencing during faults.

Oil & Gas Safety Systems: The module interfaces with flame detectors, ESD pushbuttons, and gas sensors in offshore platforms. ATEX certification and galvanic isolation prevent ignition risks in Zone 2 hazardous areas.

Manufacturing Automation: For automotive assembly lines, the ABB YPK117A 61163280 tracks robot end-effector positions, conveyor jam detection, and safety door interlocks, enabling synchronized machine control.

Water Treatment Plants: Monitors pump run/stop statuses, tank overflow switches, and filter-clogging alarms. Group isolation prevents cascading failures from wet electrical environments.

Mining & Material Handling: Detects belt misalignment, bin level limits, and emergency pull-cord activations in conveyor systems, with ruggedized tolerance to dust and vibration.

ABB YPK117A 61163280

Related Model Recommendations

YPK114A: Digital output counterpart (16 channels) for controlling relays/actuators; pairs with YPK117A for full discrete I/O solutions.

YTA110: S800 I/O baseplate; houses the YPK117A and provides power/bus connectivity.

AI835: Analog input module for integrating sensors (e.g., temperature/pressure) in the same S800 rack as YPK117A.

CI854A: Profibus DP communication interface; links the YPK117A’s I/O cluster to controllers.

PM865: AC 800M controller; processes data from YPK117A for complex logic execution.

YPK112A: 32-channel digital input module; higher-density alternative to YPK117A for large-scale applications.

SD822: Profibus DP slave module; enables remote placement of YPK117A-equipped I/O racks.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Mount the ABB YPK117A 61163280 on a compatible S800 baseplate (e.g., YTA110) within a DIN rail cabinet. Ensure ambient temperature and humidity stay within rated limits. Verify 24 VDC field power stability (±10%). Use shielded cables for field wiring and ground shields at one end. Apply ESD protection during handling.

Maintenance Suggestions: Inspect terminal blocks quarterly for loose connections or corrosion. Monitor module health via ABB’s Control Builder M diagnostics (channel errors, group faults). Replace the YPK117A only after de-energizing the baseplate unless hot-swap is configured. Keep firmware updated via ABB service packs to address compatibility issues.

Service and Guarantee Commitment

ABB guarantees the YPK117A 61163280 against defects for 18 months post-shipment under standard terms. Global technical support covers configuration, troubleshooting, and firmware updates via ABB’s service portal. Extended warranty plans (up to 5 years) include priority replacement and on-site assistance. Lifetime repair services and decade-long spare parts availability ensure lifecycle support for legacy systems. Certifications (UL/ATEX) are maintained through rigorous quality audits, reflecting ABB’s commitment to safety and reliability.