Description

Key Technical Specifications

- Model Number: ABB YPG110A YT204001-CK

- Manufacturer: ABB Industrial Automation Division

- Input Signal: 4-20mA DC (2-wire), 12-30V DC supply via input signal

- Output Pressure: 0.2-1.0 MPa (30-150 psi) for double-acting; 0.2-1.0 MPa (30-150 psi) for single-acting

- Positioning Accuracy: ±0.5% of full scale (typical); ±1.0% max

- Response Time: <0.3 seconds (90% step change, 50mm stroke)

- Feedback Mechanism: Non-contact Hall effect sensor (wear-free)

- Operating Temperature: -40°C to +85°C (-40°F to +185°F)

- Protection Rating: IP66 (dust-tight, water jet-resistant) / IP67 (temporary submersion)

- Safety Certification: IEC 61508 (SIL 2) for safety-related valve control

- Mounting Type: Direct mounting (ISO 5211), bracket mounting optional

- Air Supply: Clean, dry air (max 1.4 MPa / 200 psi), filtered to ≤40μm

- Compatibility: Globe, butterfly, ball valves (linear/rotary actuators); ABB 800xA/Symphony Plus DCS

- Certifications: CE, UL 61010, ATEX Zone 1/2, RoHS 2.0, NAMUR NE 43

ABB YPG110A YT204001-CK

Field Application & Problem Solved

In process control—refinery distillation columns, power plant steam valves, chemical reactor feed valves—valve positioning inaccuracy and safety non-compliance cause costly downtime and product loss. A Texas refinery lost $120k in off-spec gasoline when a generic positioner’s 2.5% drift led to incorrect flow control in a blending valve. Legacy positioners also fail in harsh environments: a North Dakota power plant replaced generic units quarterly ($8k/year) due to freeze damage in -35°C winters.

You’ll find this positioner mounted on critical valves: crude oil feed valves in Louisiana refineries, steam turbine bypass valves in Pennsylvania coal plants, and chemical reactor discharge valves in Minnesota facilities. Its core value is lab-grade precision + extreme-environment ruggedness + SIL 2 safety compliance. The ±0.5% accuracy eliminated the Texas refinery’s drift issues, cutting off-spec product by 95%. At the power plant, the -40°C operating range and IP67 protection eliminated winter failures—zero replacements in 4 years.

For a Florida chemical plant, SIL 2 certification ensured compliance with EPA safety regulations, avoiding $220k in non-compliance fines. Its non-contact feedback sensor also reduced maintenance costs by 60% compared to mechanical potentiometer-based generic positioners (no wear parts to replace).

Installation & Maintenance Pitfalls (Expert Tips)

- Calibration: Zero/Span Must Match Valve Stroke: Rookies use default calibration instead of matching the valve’s actual stroke (e.g., 0-100mm), causing positioning errors. A Michigan paper mill’s valve hunted between 30-40% open until we recalibrated the positioner to the valve’s 80mm stroke. Use ABB’s FieldCare software or local keypad to set zero (4mA = valve closed) and span (20mA = valve open), and verify with a stroke gauge.

- Air Supply Quality: Filter Before Installation: Unfiltered or moist air clogs internal valves, causing slow response. A Colorado refinery’s positioner failed to actuate during a process upset because the air supply had oil contamination. Install a 40μm filter-regulator (ABB 10600001) upstream, and drain condensation daily in humid environments.

- Mounting Alignment: Avoid Actuator Stem Binding: Misaligning the positioner’s feedback link causes premature wear and inaccuracy. A North Carolina chemical plant’s positioner failed after 6 months due to binding—we realigned the link to be parallel with the actuator stem and tightened fasteners to 2Nm torque. Use the ISO 5211 mounting adapter for direct mounting to eliminate alignment issues.

- Environmental Sealing: Tighten Cable Glands: Loose cable glands compromise IP66/IP67 protection, letting moisture ingress. A Gulf Coast refinery’s positioner shorted after a rainstorm because the gland wasn’t tightened. Use PTFE tape on cable threads and torque glands to 1.5Nm—inspect quarterly for corrosion in saltwater environments.

ABB YPG110A YT204001-CK

Technical Deep Dive & Overview

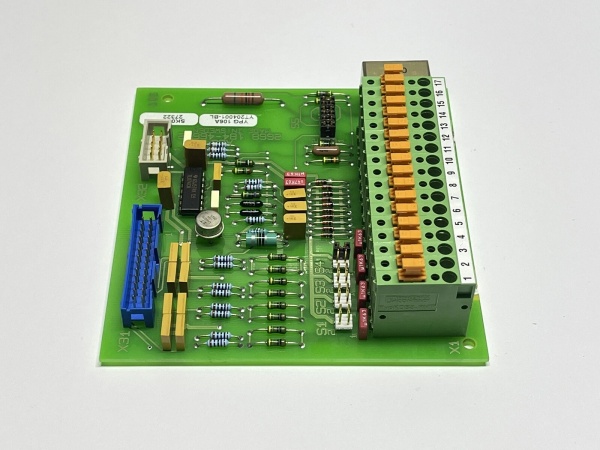

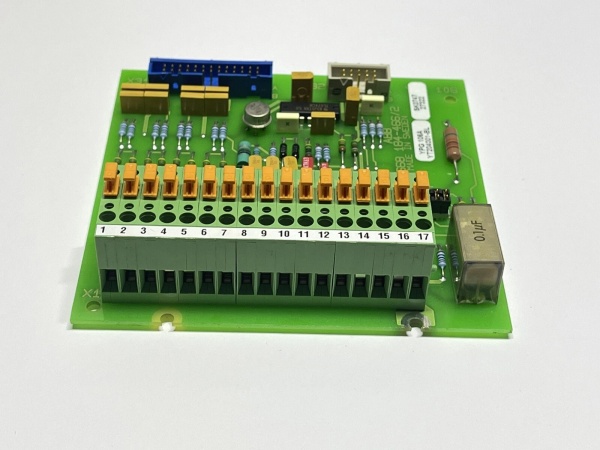

The ABB YPG110A YT204001-CK is an electro-pneumatic valve positioner engineered to convert electrical control signals into precise pneumatic pressure for valve actuation. At its core, a 16-bit microcontroller processes the 4-20mA input signal, comparing it to feedback from a non-contact Hall effect sensor (mounted on the valve stem). The controller adjusts the output pressure via a piezoelectric valve array—faster and more reliable than solenoid valves in generic positioners—delivering precise pressure to the actuator to maintain the desired valve position.

The non-contact feedback sensor eliminates wear-related drift, a major flaw in mechanical potentiometer-based positioners, ensuring long-term accuracy. For safety-critical applications, SIL 2 compliance is achieved via hardware fault detection (e.g., input signal loss, feedback failure) that triggers a fail-safe position (pre-configurable as open/closed/last position) within 0.5 seconds.

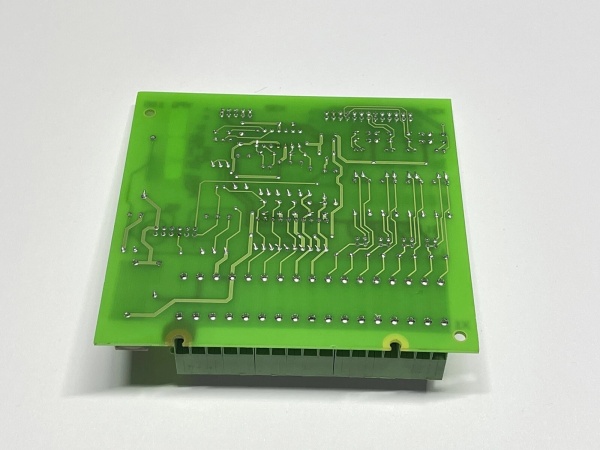

Ruggedization features include a die-cast aluminum housing, dual-layer conformal coating on the circuit board, and IP66/IP67 sealing—designed to withstand dust, water jets, and extreme temperatures. Unlike generic positioners, it’s configurable for single-acting (spring-return) or double-acting actuators via software, eliminating the need for separate models.

What sets it apart is seamless integration with ABB DCS systems—real-time position data and diagnostics are transmitted via the 4-20mA signal (HART 7 protocol) or Fieldbus, enabling predictive maintenance (e.g., alerting to air leaks or valve stiction). For facilities where valve positioning directly impacts safety, efficiency, and product quality, this positioner isn’t just a control device—it’s a reliable, low-maintenance workhorse built to perform in the harshest industrial conditions.