Description

Detailed parameter table

| Parameter name | Parameter value |

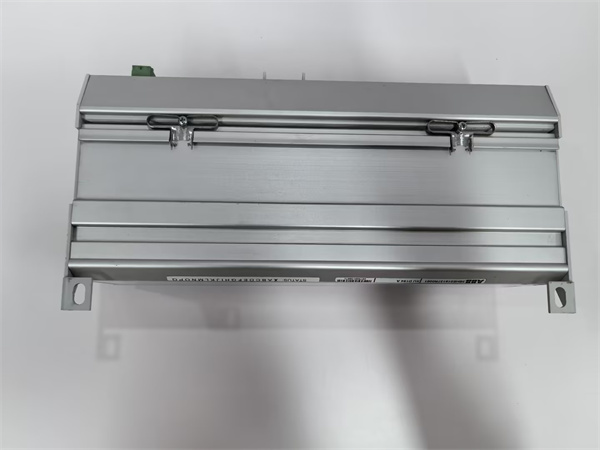

| Product model | XUD194 3BHE018137R0001 |

| Associated system | AC800PEC controller system |

| Manufacturer | ABB |

| Product category | Communication and expansion module |

| Communication interfaces | Ethernet (10/100 Mbps), PROFIBUS DP V1 (12 Mbps max) |

| Expansion capabilities | Supports up to 12 additional I/O modules |

| Data transfer rate | Up to 100 Mbps for Ethernet, 12 Mbps for PROFIBUS DP |

| Operating voltage | 24 VDC ±10% |

| Power consumption | Max 10 W |

| Operating temperature | -20°C to 60°C |

| Protection rating | IP20 |

| Dimensions | 150mm × 100mm × 50mm |

| Weight | 0.4kg |

| Certifications | CE, UL, IEC 61131-2 |

| Mounting type | DIN rail (35mm) |

ABB XUD194 3BHE018137R0001 AC800PEC

Product introduction

The ABB XUD194 3BHE018137R0001 is a pivotal communication and expansion module designed specifically for the AC800PEC controller system. In the realm of industrial automation, this module plays a crucial role in enabling seamless data exchange and system scalability.

As a communication hub, it features Ethernet and PROFIBUS DP V1 interfaces. The Ethernet connection allows for high – speed data transfer, facilitating integration with enterprise networks, remote monitoring systems, and other Ethernet – based devices. This enables operators to access real – time data from the AC800PEC system, view historical trends, and perform remote configuration changes. The PROFIBUS DP V1 interface, on the other hand, is ideal for connecting to a wide range of field devices such as sensors, actuators, and other PROFIBUS – compliant modules. It provides a reliable and deterministic communication link, ensuring accurate and timely control of industrial processes.

In terms of expansion, the ABB XUD194 3BHE018137R0001 is engineered to support the addition of up to 12 additional I/O modules. This expandability is essential for adapting the AC800PEC system to the changing needs of industrial applications. Whether it’s adding more digital inputs to monitor additional sensors or more analog outputs to control complex actuators, this module allows for a flexible and customizable automation solution.

Core advantages and technical highlights

Dual – protocol communication: The combination of Ethernet and PROFIBUS DP V1 interfaces on the ABB XUD194 3BHE018137R0001 offers unparalleled connectivity options. It can bridge the gap between the high – level enterprise network and the low – level field devices. For example, in a large – scale manufacturing plant, the Ethernet interface can be used to send production data to the management’s enterprise resource planning (ERP) system, while the PROFIBUS DP V1 interface controls the operation of individual machines on the factory floor. This dual – protocol support simplifies system integration and reduces the need for multiple communication gateways.

High – speed data transfer: With a maximum data transfer rate of 100 Mbps for Ethernet and 12 Mbps for PROFIBUS DP, the module ensures fast and efficient data exchange. This is critical for applications where real – time control and monitoring are essential, such as in high – speed packaging lines or precision manufacturing processes. The quick transfer of data allows for rapid response times, minimizing production delays and improving overall system performance.

Scalability: The ability to support up to 12 additional I/O modules provides significant flexibility in system design. A small – scale automation project can start with a basic configuration and gradually expand as the production requirements grow. This scalability not only saves initial investment costs but also future – proofs the system. For instance, in a food and beverage factory, if new production lines are added or existing processes are modified, the AC800PEC system can be easily expanded using the ABB XUD194 3BHE018137R0001 module without major re – engineering.

Reliable operation: Designed to operate in a wide temperature range from – 20°C to 60°C, the ABB XUD194 3BHE018137R0001 is suitable for installation in various industrial environments, from cold storage facilities to hot processing plants. Its IP20 protection rating safeguards against dust and small objects, ensuring reliable performance even in less – than – ideal conditions. Additionally, the module is compliant with industry – standard certifications such as CE, UL, and IEC 61131 – 2, which guarantees its quality and safety.

Typical application scenarios

In automotive manufacturing, the ABB XUD194 3BHE018137R0001 is used in the AC800PEC – based control systems for robotic assembly lines. The Ethernet interface is used to communicate with the plant – wide control network, which manages production scheduling and quality control data. The PROFIBUS DP V1 interface connects to the numerous sensors and actuators on the robots, ensuring precise movement and operation. As the production line expands or new models are introduced, the module’s expandability allows for the addition of more I/O modules to accommodate the new requirements.

Within chemical processing plants, the module is deployed in the control systems for complex chemical reactions. The Ethernet interface enables real – time data transfer to the plant’s central control room, where operators can monitor process variables such as temperature, pressure, and flow rates. The PROFIBUS DP V1 interface is used to connect to field – mounted instruments and valves that control the chemical processes. The module’s ability to operate in harsh environments, with its wide temperature range and IP20 protection, makes it suitable for use in chemical plants where corrosive gases and high temperatures are common.

In smart building automation systems, the ABB XUD194 3BHE018137R0001 is integrated into the AC800PEC system to manage various building services. The Ethernet interface is used to connect to the building management system (BMS), which allows facility managers to control and monitor lighting, HVAC, and security systems from a central location. The PROFIBUS DP V1 interface is used to connect to local sensors and actuators, such as occupancy sensors, temperature controllers, and motorized dampers. The module’s expandability is useful in large – scale buildings where new areas may be added or existing systems need to be upgraded.

ABB XUD194 3BHE018137R0001 AC800PEC

Related model recommendations

ABB XIO160: An I/O module that can be expanded using the ABB XUD194 3BHE018137R0001 module. It offers 16 digital inputs and outputs, suitable for basic monitoring and control applications.

ABB AC800PEC PM886: The main controller unit of the AC800PEC system, which works in tandem with the ABB XUD194 3BHE018137R0001 module for overall system operation.

ABB PROFIBUS DP cable: A specialized cable for connecting the ABB XUD194 3BHE018137R0001 to PROFIBUS – compliant field devices, ensuring reliable communication.

ABB Ethernet switch: An Ethernet switch can be used to expand the Ethernet network connectivity of the ABB XUD194 3BHE018137R0001, allowing for connection to multiple devices.

ABB DriveWindow Light: Software that can be used to configure and monitor drives connected to the AC800PEC system via the ABB XUD194 3BHE018137R0001 module.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the ABB XUD194 3BHE018137R0001, ensure that the 35mm DIN rail is securely mounted in the control cabinet. Verify that the operating voltage of 24 VDC ±10% is available and properly grounded. Required tools include a torque screwdriver (0.5 – 0.8 Nm) for mounting the module on the DIN rail and a cable crimper for connecting Ethernet and PROFIBUS DP cables. The Ethernet cable should be a shielded Cat5e or higher – grade cable, and the PROFIBUS DP cable should be a specialized cable with proper impedance matching.

Maintenance suggestions: Regularly inspect the module for loose connections, especially the Ethernet and PROFIBUS DP cable connectors. Check for signs of overheating, such as discoloration or abnormal smell. Monitor the module’s power consumption periodically to detect any potential faults. Every six months, perform a communication test to ensure that the Ethernet and PROFIBUS DP interfaces are functioning correctly. If any issues are detected, consult the ABB technical support or replace the module with an ABB – approved unit to maintain system integrity.

Service and guarantee commitment

The ABB XUD194 3BHE018137R0001 comes with a 36 – month warranty from the date of installation. ABB guarantees to replace any defective module within 72 hours for critical applications, minimizing downtime in industrial operations. Technical support is available 24/7, with access to ABB’s team of automation experts. Online resources include detailed user manuals, configuration guides, and troubleshooting tips. Customers can also opt for extended service contracts that include preventive maintenance, software updates, and priority support, ensuring the long – term reliability of the module within the AC800PEC system.