Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | ABB UNITROL1010 |

| Manufacturer | ABB |

| Product Category | Digital Excitation System Controller |

| Compatible Generators | Synchronous Machines (0.5-50 MVA) |

| Control Modes | Automatic Voltage Regulator (AVR), Field Current Control, Power System Stabilizer (PSS) |

| Input Voltage Range | 90-264 V AC/DC (Self-excited or PMG-supplied) |

| Field Current Rating | 10 A Continuous (20 A for 30s) |

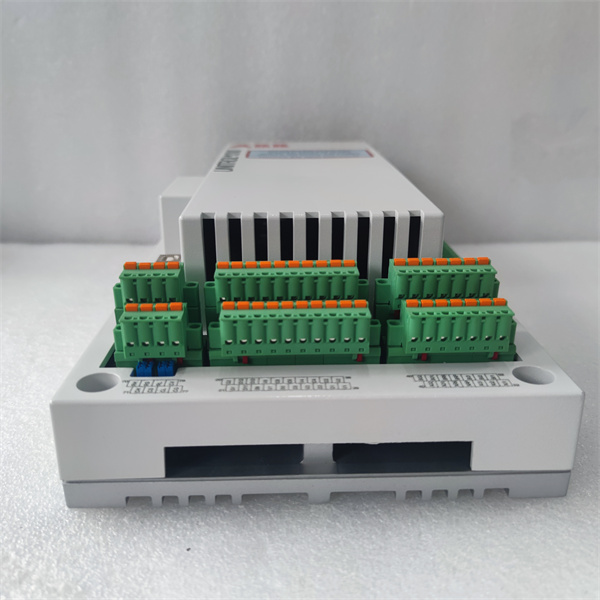

| Communication Interfaces | 2x RS-485 (Modbus RTU), Ethernet TCP/IP (optional) |

| Protection Functions | Over-excitation, Under-excitation, Loss-of-Field, V/Hz Protection |

| Measurement Accuracy | ±0.2% (Voltage), ±0.5% (Current) |

| Operating Temperature | -25°C to +55°C |

| Protection Rating | IP20 (Chassis), IP54 (Front Panel) |

| Display | 128×64 Graphic LCD with Keypad |

| Certifications | UL 508, CE, IEC 61800-5-1 |

ABB UNITROL1010

Product Introduction

The ABB UNITROL1010 represents ABB’s advanced digital solution for synchronous machine excitation control, delivering precision voltage regulation for generators across industrial and power generation applications. As a core component of ABB’s excitation systems portfolio, this compact controller provides comprehensive automatic voltage regulation (AVR), field current control, and built-in Power System Stabilizer (PSS) functionality. Engineered for reliability, the UNITROL1010 integrates sophisticated algorithms to maintain grid stability during load fluctuations while protecting generators from damaging electrical transients.

Operating within ABB’s UNITROL platform, this controller bridges traditional excitation technology with modern digital capabilities. Its technical positioning focuses on mid-range generators requiring robust performance without complex infrastructure. In the automation ecosystem, the ABB UNITROL1010 serves as the intelligence behind generator synchronization, reactive power management, and fault ride-through capabilities, significantly enhancing plant stability while reducing commissioning complexity compared to analog systems.

Core Advantages and Technical Highlights

The ABB UNITROL1010 delivers exceptional operational value through innovative engineering:

Adaptive Control Architecture: Patented PID algorithms with auto-tuning capability maintain voltage within ±0.25% during load rejection scenarios. Real-time parameter adaptation compensates for generator saturation effects without manual intervention.

Multi-Layer Protection: Integrated IEEE 421.4-compliant protection functions (over/under-excitation, V/Hz limiting) operate independently from control loops. Dual redundant measurement chains ensure fail-safe operation during sensor failures.

Grid-Stability Enhancement: Built-in Power System Stabilizer (PSS) dampens low-frequency oscillations (0.1-2 Hz range) using acceleration power input, improving transient stability during grid disturbances.

Universal Compatibility: Supports self-excited, PMG-excited, or auxiliary-powered configurations. Wide input voltage range (90-264V AC/DC) eliminates need for external converters.

Intuitive Commissioning: Guided setup wizard on backlit LCD simplifies parameterization. Pre-configured templates for common generator types (gas, hydro, diesel) reduce configuration time by 70%.

Cybersecurity-Ready: Hardware-level password protection with role-based access control. Optional Ethernet module supports encrypted IEC 61850 communication.

Typical Application Scenarios

The ABB UNITROL1010 excels in demanding power generation environments:

Industrial Cogeneration Plants: Controls 5-20 MW gas turbines in paper mills, maintaining voltage stability during motor starting surges while providing PSS damping for grid interconnection.

Hydroelectric Stations: Manages excitation for 1-15 MVA hydro generators with adaptive compensation for water hammer effects during gate adjustments.

Marine Power Systems: Regulates shipboard diesel generators with anti-islanding protection, compensating for sudden load steps from thrusters.

Emergency Backup Facilities: Ensures seamless transition for hospital/data center generators with <20ms response to grid failure detection.

Mining Operations: Withstands vibration (5g) and temperature extremes while maintaining voltage during crusher motor startups in remote locations.

In each application, the UNITROL1010 prevents costly downtime by maintaining voltage stability and protecting generator windings from thermal damage.

ABB UNITROL1010

Related Model Recommendations

ABB UNITROL1020 – Enhanced version with dual-channel redundancy for critical generation assets.

ABB AEX510 – Excitation protection module complementing UNITROL1010‘s control functions.

ABB UNS0881a – Advanced HMI panel for centralized monitoring of multiple UNITROL1010 units.

ABB UMC100 – Universal machine controller for integrated generator protection/control.

ABB REG670 – Generator protection relay for comprehensive backup protection.

Installation, Commissioning and Maintenance Instructions

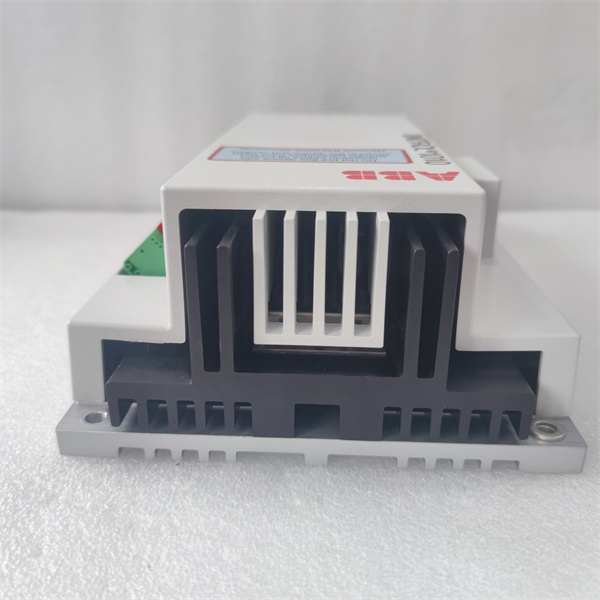

Installation Preparation: Ensure generator parameters (nameplate data) are available. Verify clean, dry environment meeting IP54 requirements. Use shielded twisted-pair cables for all analog signals with separation >15cm from power cables. Ground chassis directly to generator frame using 6mm² copper wire. Allow minimum 100mm clearance for ventilation.

Maintenance Suggestions: Perform monthly visual inspections for dust accumulation. Calibrate measurement circuits annually using precision shunt. Monitor field current ripple (<5% peak-peak) via diagnostic menu. Backup parameters to USB before firmware updates. Replace cooling fans every 50,000 operating hours. Validate protection settings during scheduled generator testing.

Service and Guarantee Commitment

ABB provides a 36-month warranty for the UNITROL1010 covering material and manufacturing defects. Our global support includes:

24/7 technical assistance via ABB’s Excitation Expert Network

On-site commissioning support within 72 hours request

Lifetime firmware updates with backward compatibility

Complimentary training on operation and diagnostics

15-year minimum product lifecycle commitment

Extended service plans offering predictive maintenance analytics and priority component replacement

Comprehensive documentation packages (FAT protocols, SIL reports) available for safety-critical installations.