Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

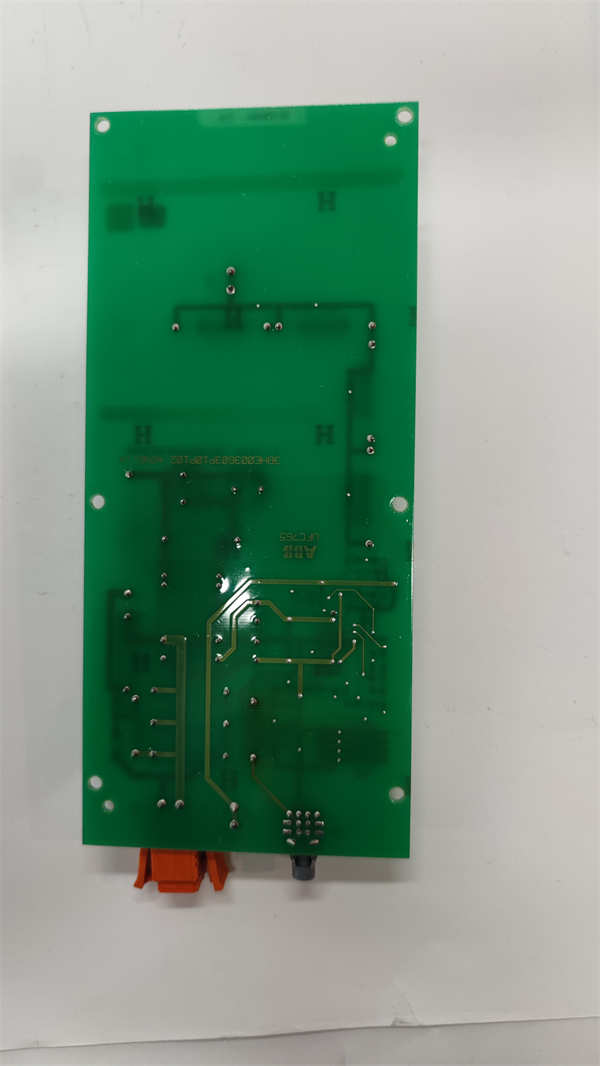

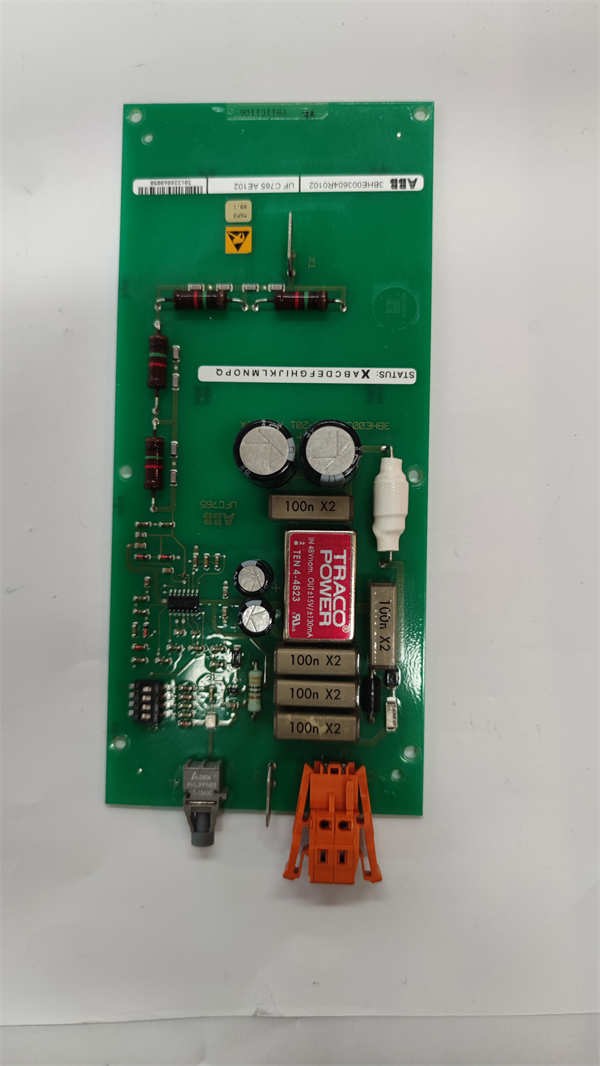

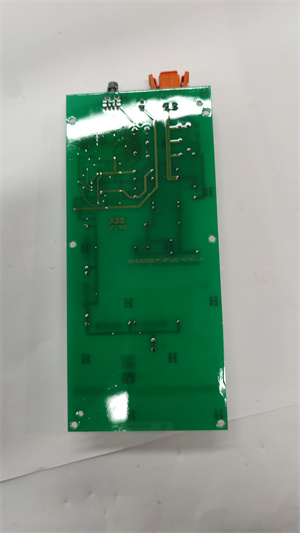

| Product Model | ABB UFC765AE102 3BHE003604R0102 |

| Manufacturer | ABB |

| Product Category | Safety Process Controller (800xA System) |

| Compatible System | ABB Ability™ 800xA Distributed Control System |

| Processor | Dual Power Architecture (ARM + FPGA) |

| Safety Certification | SIL 3 (IEC 61508), SIL 3 (IEC 61511) |

| Main Memory | 2 GB DDR4 RAM, 128 GB Industrial SSD |

| Safety Logic Execution Time | <10 ms (typical) |

| Communication Interfaces | 4x Gigabit Ethernet, 2x PROFINET IRT, 2x USB 3.1 |

| Redundancy Support | TÜV-certified 1oo2D |

| Operating Temperature | -40°C to +70°C (conformal coating) |

| Power Supply | 24 V DC ±20% (dual redundant inputs) |

| Power Consumption | 35 W (nominal) |

| Vibration Resistance | 5 g (10-150 Hz, IEC 60068-2-6) |

| Dimensions (W x H x D) | 128 mm x 223 mm x 165 mm |

| Certifications | ATEX II 3G Ex ec IIC T4 Gc, UL Class I Div 2 |

ABB UFC765AE102 3BHE003604R0102

Product Introduction

The ABB UFC765AE102 3BHE003604R0102 stands at the forefront of ABB’s mission-critical control technology as a SIL 3-certified Safety Process Controller within the Ability™ 800xA Distributed Control System. Engineered for ultra-reliable operation in hazardous environments, this controller executes both standard process control and safety instrumented functions (SIFs) within a single unified platform. The UFC765AE102 integrates deterministic control logic (<10ms cycle times) with advanced safety algorithms, enabling comprehensive process shutdown management while maintaining continuous production oversight.

As the computational core of safety-critical systems, this controller leverages ABB’s patented “Dual Power Architecture” combining ARM processors for conventional control with FPGA-based safety logic executors. Its technical positioning bridges operational technology (OT) and functional safety requirements, eliminating the need for separate safety systems. Within 800xA ecosystems, the ABB UFC765AE102 3BHE003604R0102 delivers unparalleled value through reduced engineering complexity, unified diagnostics, and minimized hardware footprint for applications where failure is not an option.

Core Advantages and Technical Highlights

The ABB UFC765AE102 3BHE003604R0102 redefines safety control through groundbreaking innovations:

Certified Safety Architecture: TÜV-certified 1oo2D redundancy with <15ms switchover and voter diagnostics. Dual-channel diverse processing (ARM + FPGA) prevents common cause failures, achieving PFDavg <10⁻⁵ for SIL 3 applications.

Extreme Environment Resilience: Operates at -40°C to +70°C with conformal-coated electronics and corrosion-resistant housing. ATEX/IECEx Zone 2/22 certifications enable installation in explosive dust/gas environments without additional enclosures.

Deterministic Performance: Hybrid processing handles 200+ safety functions concurrently with 5ms execution windows. Integrated hardware timestamps ensure µs-level synchronization for critical interlocks.

Cybersecurity Fortification: Hardware root-of-trust with secure boot, encrypted storage (AES-256), and runtime integrity monitoring compliant with IEC 62443-4-2 SL3.

Seamless Integration: Native PROFINET IRT support enables motion-synchronized safety functions. Dual 800xA control network interfaces maintain <1ms peer-to-peer communication.

Advanced Diagnostics: Predictive health monitoring tracks component degradation (SSD wear, capacitor ESR). Integrated FMEA reporting simplifies safety validation.

Typical Application Scenarios

The ABB UFC765AE102 3BHE003604R0102 delivers critical protection in high-risk industries:

Offshore Oil & Gas: Manages emergency shutdown (ESD) and fire/gas systems on FPSOs, withstanding salt spray and -30°C Arctic conditions while maintaining SIL 3 integrity during platform motions.

Chemical Batch Reactors: Coordinates exothermic reaction safeguards with <50ms trip times, integrating pressure/temperature SIFs with recipe control in ATEX Zone 1 areas.

Power Generation Turbines: Executes turbine overspeed protection (ISO 21789) while synchronizing with grid frequency controls using hardware-timed logic at 1ms resolution.

Pharmaceutical API Synthesis: Ensures GMP-compliant safety interlocks for high-pressure hydrogenation with audit trail encryption (21 CFR Part 11).

Mining Processing Plants: Controls dust explosion prevention systems in Zone 22 areas, surviving 5g vibration from grinding mills.

In each scenario, the UFC765AE102 prevents catastrophic failures while maximizing process availability through integrated safety/control architecture.

ABB UFC765AE102 3BHE003604R0102

Related Model Recommendations

ABB PM803F – SIL 3-certified primary controller for non-safety process control.

ABB SD826 – SIL 3 I/O module for direct sensor/actuator interfacing.

ABB CI873 – PROFINET controller module for IRT motion integration.

ABB TU833 – Ruggedized Ethernet switch for safety network segmentation.

ABB SAFEIO1200 – Interface for third-party safety devices.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Verify Class I Div 2/Zone 2 area classification. Use ESD-safe tools and grounding straps. Mount on 35mm DIN rail with vibration-dampening clips (torque 0.8 N·m). Connect redundant 24V DC power via spring-clamp terminals. For Zone 1, install in ABB 3HAC065297-001 certified enclosure. Maintain 75mm lateral clearance for heat dissipation.

Maintenance Suggestions: Perform quarterly firmware validation via digital signature check. Monitor SSD health through 800xA Diagnostics Advisor (replace at 95% wear indication). Calibrate hardware clock annually using PTP grandmaster. Validate safety logic every 24 months via integrated test sequence generator. Replace backup supercapacitor every 8 years.

Service and Guarantee Commitment

ABB warrants the UFC765AE102 3BHE003604R0102 for 36 months. Our global support includes:

24/7 Critical Response: On-site safety engineers within 12 hours for SIL 3 system faults

Lifecycle Assurance: 20-year product availability with migration path commitments

Safety Certification: TÜV-maintained SIL 3 documentation packages (FMEDA, SRS)

Preventive Maintenance: Predictive analytics based on controller health telemetry

Firmware Integrity: Digitally-signed updates with version rollback capability

Training: Certified Functional Safety Engineer programs with hands-on labs

Extended service agreements include spare controller provisioning with pre-validated application clones for ≤2-hour mean repair time.