Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

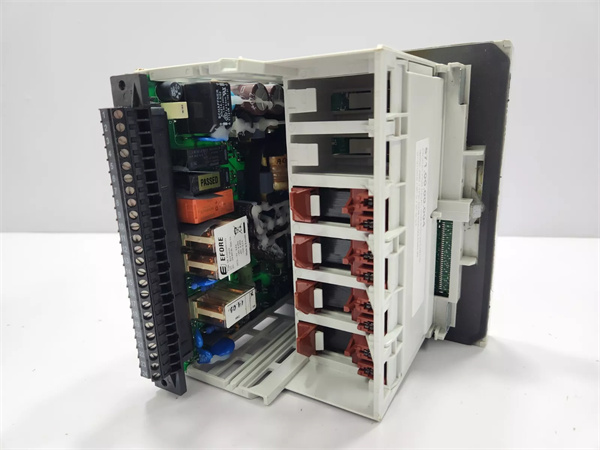

| Product Model | REM610C55HCNN02 |

| Manufacturer | ABB |

| Product Category | Motor Protection Relay |

| Rated Voltage | 24–250 V DC / 48–265 V AC |

| Protection Functions | Overload, Phase Loss, Locked Rotor, Earth Fault, Thermal O/L |

| Control Inputs | 5 binary (24–250V DC) |

| Relay Outputs | 4 programmable (5A @ 250V AC) |

| Communication | PROFIBUS DP, HART 7, Ethernet (dual port) |

| Measurement Accuracy | ±1% of reading (current), ±0.5% (voltage) |

| Operating Temperature | -40°C to +70°C |

| Housing Protection | IP20 (front), IP00 (terminals) |

| Mounting | DIN rail (TS35) |

| Dimensions (W×H×D) | 126 × 138 × 129 mm |

| Certifications | UL 508, IEC 60255, DNV GL, ATEX Zone 2 |

REM610C55HCNN02

Product Introduction

The ABB REM610C55HCNN02 is an advanced digital motor protection relay designed for medium-voltage motors up to 7.2 kV. Part of ABB’s Relion® 600 series, this intelligent device provides comprehensive protection, control, and condition monitoring for critical motors in industrial applications. The ABB REM610C55HCNN02 integrates seamlessly with ABB Ability™ enabled systems, offering real-time thermal modeling and adaptive protection algorithms.

Engineered for harsh environments, the ABB REM610C55HCNN02 features dual Ethernet ports for redundant communication alongside PROFIBUS DP and HART protocols. Its core functionality includes advanced motor diagnostics (starts/hour monitoring, rotor bar detection) and programmable logic for custom protection schemes. The ABB REM610C55HCNN02 serves as the central nervous system for motor management, preventing costly downtime through predictive fault detection and precise trip coordination.

Core Advantages and Technical Highlights

ABB REM610C55HCNN02 delivers unparalleled motor protection intelligence:

Adaptive Thermal Protection: Utilizes real-time thermal modeling based on motor parameters and ambient temperature. The ABB REM610C55HCNN02 continuously calculates stator/rotor thermal capacity, providing 5% more operational margin than fixed thermal curves while preventing insulation degradation.

Multi-Protocol Connectivity: Native PROFIBUS DP-V1 and HART 7 support enables simultaneous control communication (cyclic data) and diagnostic access (acyclic). Dual Ethernet ports (RJ45) allow daisy-chaining for ring topologies with <3ms redundancy switchover.

High-Speed Fault Detection: Detects phase imbalances within 20ms and stator ground faults <5ms using directional earth fault protection. The ABB REM610C55HCNN02 captures waveform data for 128 cycles pre/post-trip for forensic analysis.

Cyber Secure Architecture: Hardware-enforced IEC 62443-3-3 compliance with role-based access control, audit trails, and encrypted firmware updates. Physical key switch prevents unauthorized configuration changes.

Space-Optimized Design: At just 126mm wide, the ABB REM610C55HCNN02 fits standard motor control centers. Front-mounted USB port facilitates offline configuration without communication wiring.

Typical Application Scenarios

The ABB REM610C55HCNN02 excels in mission-critical motor protection:

In offshore platforms, the relay protects seawater injection pumps against saltwater ingress failures. Its ATEX Zone 2 certification allows installation in hazardous areas, while HART communication enables valve positioner diagnostics through the same wiring.

For mining conveyors, the ABB REM610C55HCNN02 prevents belt damage through torque-based stall detection. Rotor bar monitoring identifies cracked bars before catastrophic failure, and -40°C operation ensures reliability in arctic facilities.

In HVAC chillers, adaptive thermal modeling allows 10% overload during peak demand without tripping. The ABB REM610C55HCNN02‘s power quality measurements (THD, unbalance) optimize energy consumption across motor clusters.

Related Model Recommendations

REM615: Feeder protection counterpart to REM610C55HCNN02 in switchgear.

RET615: Transformer protection relay complementing REM610C55HCNN02 systems.

CM-PBS: PROFIBUS interface module for legacy controllers connecting to REM610C55HCNN02.

ABB 1SAP250400R0001: Current transformer set for REM610C55HCNN02 installations.

RDU610: Local display unit for REM610C55HCNN02 parameterization.

ABB 1KHL 963001: DIN rail kit for vibration-resistant mounting of REM610C55HCNN02.

PCM600: Engineering software for configuring REM610C55HCNN02 protection schemes.

REM610C55HCNN02

Installation, Commissioning and Maintenance Instructions

Installation Preparation:

Verify CT ratios match motor nameplate. Maintain 50mm clearance above/below relay for cooling. Ground shield wires at source only. Use ABB-approved torque screwdriver (0.8 Nm) for terminals. Disconnect motor before energizing ABB REM610C55HCNN02.

Maintenance Suggestions:

Perform annual thermal calibration via “Learn” function during cold start. Monitor “Insulation Resistance” trend in ABB Ability™. Replace backup battery (1SAP141200R0001) every 5 years. Verify firmware updates using ABB’s Secure Delivery Server. Replace ABB REM610C55HCNN02 if “Watchdog” LED flashes red continuously.

Service and Guarantee Commitment

ABB provides a 5-year warranty for REM610C55HCNN02, including firmware updates and cybersecurity patches. Global technical support includes 24/7 access to ABB’s Protection Cloud analytics. All relays undergo 500-hour burn-in testing with simulated motor faults. Extended service agreements include on-site calibration and lifecycle management. ABB’s Cyber Security Emergency Response Team (CSERT) provides vulnerability monitoring for installed base.