Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | PFCL201C 20KN 3BSE023409R2 |

| Manufacturer | ABB |

| Product category | Load cell for tension measurement |

| Nominal load capacity | 20 KN |

| Extended load (±1% accuracy) | 30 KN |

| Max permitted load | 200 KN (without permanent change) |

| Permitted transverse force | 10 KN (within accuracy) |

| Permitted axial load | 5 KN (within accuracy) |

| Spring constant | 1000 KN/mm |

| Measurement principle | Strain gauge – based |

| Construction material | Stainless steel (single – piece machined) |

| Connection type | Pluggable connection cable |

| Operating temperature range | -20 °C to +60 °C |

| Storage temperature range | -40 °C to +85 °C |

| Humidity range | 5% – 95% non – condensing |

| Protection rating | IP65 (dust – tight and water – resistant) |

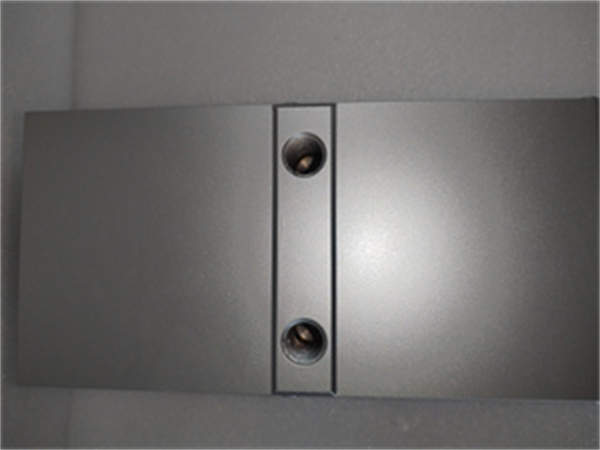

| Dimensions (approx.) | Length: 350 mm, Width: 150 mm, Height: 120 mm |

| Mounting type | Mounted under roll bearings (for strip tension measurement) |

| Weight | 37 kg |

| Calibration and compensation | Pre – calibrated and temperature – compensated |

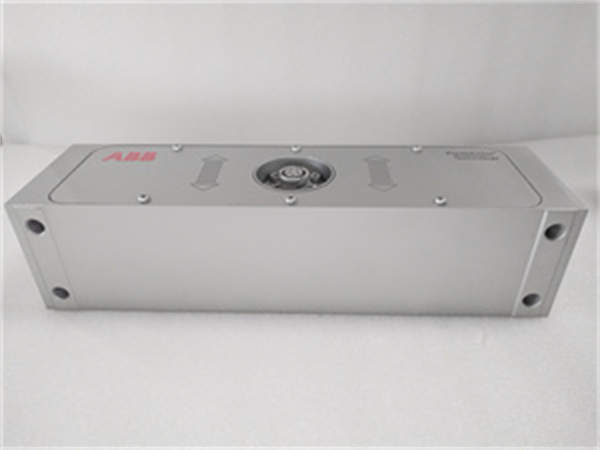

ABB PFCL201C 20KN 3BSE023409R20

Product introduction

The ABB PFCL201C 20KN 3BSE023409R2 is a high – precision load cell, specifically engineered for strip tension measurement in industrial automation and manufacturing processes. As a crucial component of ABB’s PressGuide® strip tension measuring system, this load cell plays a vital role in ensuring the accurate control and monitoring of strip – related operations.

The PFCL201C 20KN is designed to measure forces perpendicular to the mounting surface. It is installed beneath roll bearings, where it can precisely detect the tension forces acting on strips as they pass over the rolls. With its advanced strain – gauge – based measurement principle, the load cell can convert mechanical forces into electrical signals, which can then be easily processed and analyzed by associated control systems. This makes it an essential element for maintaining the quality and efficiency of production lines that rely on strip – based materials, such as in the metalworking, paper, and plastic industries.

Core advantages and technical highlights

High – precision measurement: The PFCL201C 20KN offers exceptional measurement accuracy, with an extended load accuracy of ±1% up to 30 KN. This high – level precision is crucial for applications where even the slightest variation in strip tension can affect the quality of the final product. In a metal stamping plant, for example, accurate strip tension measurement ensures that the metal sheets are fed evenly into the stamping machines, resulting in consistent and high – quality stamped parts.

Robust construction: Machined from a single piece of stainless steel, the load cell is highly resistant to wear, corrosion, and mechanical stress. The stainless – steel construction not only provides durability but also makes it suitable for use in harsh industrial environments, such as those with high humidity or exposure to corrosive substances. Additionally, the IP65 protection rating ensures that the load cell is dust – tight and can withstand water jets from any direction, further enhancing its reliability in tough operating conditions.

Temperature compensation: Each PFCL201C 20KN load cell comes pre – calibrated and temperature – compensated. This means that it can maintain accurate measurement performance over a wide range of operating temperatures, from – 20 °C to +60 °C. Temperature – induced errors can be a significant problem in industrial settings, but the built – in temperature compensation feature of this load cell mitigates such issues. In a paper mill, where the operating environment can experience temperature fluctuations, the load cell can accurately measure strip tension without being affected by the changing temperatures.

Versatile mounting options: The load cell is designed for easy installation under roll bearings, which is a common setup in strip – handling machinery. Its mounting design allows for quick and secure attachment, minimizing installation time and effort. The four – screw mounting arrangement on both the base and the bearing housing ensures a stable connection, enabling the load cell to accurately measure forces without any movement or misalignment issues.

Multiple load range options: While the nominal load capacity of the PFCL201C 20KN is 20 KN, the load cell is part of a family of products that offer a range of nominal load options from 5 KN to 50 KN. This flexibility allows users to choose the most appropriate load cell for their specific application requirements. For applications with lighter strip materials and lower tension requirements, a 5 KN or 10 KN load cell from the same family may be suitable, while heavier – duty applications can benefit from the 20 KN or 50 KN variants.

Typical application scenarios

Metalworking industry: In a steel rolling mill, the PFCL201C 20KN is used to measure the tension of steel strips as they are being rolled into various thicknesses. By accurately monitoring the strip tension, operators can ensure that the rolling process is consistent and that the final steel products meet the required quality standards. If the strip tension is too high or too low, it can lead to defects such as uneven thickness or surface imperfections. The load cell’s high – precision measurement capabilities help to prevent such issues, resulting in improved product quality and reduced waste.

Paper and packaging industry: In a paper manufacturing plant, the PFCL201C 20KN plays a crucial role in measuring the tension of paper rolls during the production process. Proper paper strip tension is essential for ensuring smooth paper unwinding, cutting, and folding operations. If the tension is not maintained within the correct range, it can cause paper jams, wrinkles, or tears. The load cell provides real – time tension data, allowing the control system to adjust the paper – handling equipment accordingly and maintain a continuous and efficient production line.

Plastic film production: In a plastic film manufacturing facility, the PFCL201C 20KN is used to measure the tension of plastic films as they are extruded and processed. Accurate tension control is necessary to produce plastic films with uniform thickness and quality. The load cell enables the control system to adjust the speed and tension of the film – handling equipment, ensuring that the plastic films are produced with the desired properties. This is particularly important in applications where the plastic films are used for packaging sensitive products, such as food or electronics, where any defects in the film can compromise the integrity of the packaged items.

Textile industry: In a textile mill, the PFCL201C 20KN can be used to measure the tension of yarn or fabric strips during weaving, knitting, or dyeing processes. Maintaining the correct tension in textile materials is essential for producing high – quality fabrics. Incorrect tension can lead to fabric distortion, uneven dyeing, or breakage of the yarn. The load cell helps textile manufacturers to optimize the tension control in their production processes, resulting in improved fabric quality and reduced production costs.

ABB PFCL201C 20KN 3BSE023409R20

Related model recommendations

ABB PFCL201CE: This is a variant of the PFCL201 series with a fixed connection cable and a protective hose. It may be suitable for applications where a more permanent and protected cable connection is required, such as in environments with potential cable damage risks.

ABB PFCL201CD: Another variant with a fixed PTFE – insulated connection cable and an acid – proof cable gland. It is ideal for applications in harsh chemical environments where resistance to acid and other corrosive substances is crucial.

ABB PFCL201C (5 KN): For applications that require lower load – measuring capabilities, this 5 KN version of the PFCL201C can provide accurate tension measurement for lighter – duty strip – handling operations.

ABB PFCL201C (50 KN): In contrast, for applications dealing with heavier loads and higher strip tensions, the 50 KN variant of the PFCL201C can handle the increased forces while maintaining high – precision measurement.

Installation, commissioning and maintenance instructions

Installation preparation: Before installation, ensure that the mounting location under the roll bearings is clean and free of any debris or obstructions. Check the dimensions of the mounting area to ensure a proper fit for the PFCL201C 20KN load cell. Verify that the power supply (if applicable for signal conditioning or communication) is of the correct voltage and meets the load cell’s requirements. When handling the load cell, use appropriate lifting equipment due to its 37 – kg weight to avoid any injuries.

Commissioning process: After installation, connect the load cell to the associated control system or data acquisition unit according to the wiring diagram provided in the product documentation. Ensure that all connections are secure. Power on the system and perform a calibration check using known reference loads. The load cell should be calibrated in the same environment where it will be operating to account for any temperature or other environmental factors. Follow the calibration procedures outlined in the user manual to set the zero point and adjust the sensitivity of the load cell as needed.

Maintenance suggestions: Regularly inspect the load cell for any signs of physical damage, such as cracks in the stainless – steel housing or loose connections. Clean the load cell periodically to remove dust, dirt, or any other contaminants that may have accumulated on its surface. Check the calibration of the load cell at regular intervals, especially if the operating conditions have changed significantly. In case of any abnormal measurement readings, refer to the troubleshooting section of the product manual or contact ABB’s technical support team for assistance. If replacement parts are required, use only ABB – approved spares to ensure the continued performance and reliability of the load cell.

Service and guarantee commitment

ABB provides a standard 2 – year warranty for the PFCL201C 20KN 3BSE023409R2 load cell, covering any manufacturing defects. ABB’s global technical support team is available 24/7 to assist customers with installation, commissioning, calibration, and troubleshooting. They can offer remote support through online communication channels, providing real – time guidance and solutions. In cases where on – site assistance is necessary, trained technicians can be dispatched to the customer’s location. ABB also provides regular product updates, including software (if applicable) and technical documentation, to help customers optimize the performance of the load cell and stay informed about any new features or improvements. This commitment reflects ABB’s dedication to ensuring the long – term reliability and performance of its industrial measurement products.