Description

Key Technical Specifications

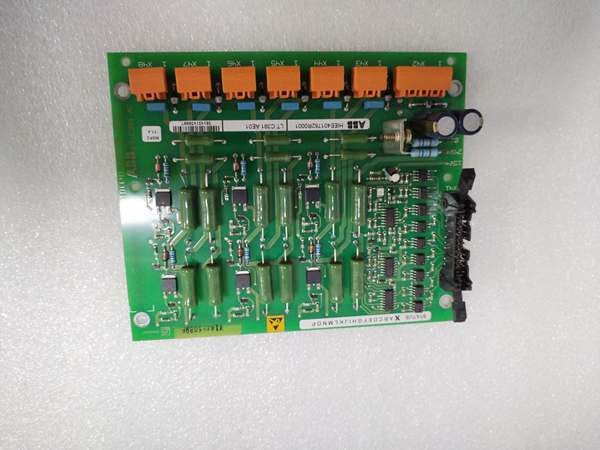

- Model Number: LTC391AE01 (Assembly No.: HIEE401782R0001)

- Manufacturer: ABB Industrial Automation Division

- System Compatibility: ABB 800xA DCS, Symphony Plus, Advant OCS, Industrial PLC Systems

- Input Channels: 2 isolated pulse input channels (independently configurable)

- Input Signal Types: Dry contact, NPN/PNP open collector, 24VDC active signal

- Maximum Input Frequency: 100kHz per channel

- Input Voltage Range: 18-30VDC

- Isolation: 500VAC channel-to-channel, channel-to-system isolation

- Pulse Modes: Totalize (counting), Frequency measurement, Period measurement, Duration measurement

- Resolution: 32-bit counter for totalization mode

- Accuracy: ±0.01% of reading (frequency mode), ±0.05% of reading (period mode)

- Response Time: 10μs per channel

- Communication Interface: Profibus DP, Ethernet/IP (via backplane)

- Power Requirements: 24VDC ±20% (max power consumption: 5W)

- Status Indicators: 4 x multi-color LED indicators (power, communication, channel 1 status, channel 2 status)

- Mechanical Specifications:

- Dimensions (W×H×D): 100mm × 160mm × 40mm

- Weight: 0.3kg (0.66 lbs)

- Mounting: DIN rail mount or panel mount (IP20 front panel)

- Environmental Ratings:

- Operating Temperature: -20°C to +60°C (-4°F to 140°F)

- Storage Temperature: -40°C to +85°C (-40°F to 185°F)

- Humidity: 5% to 95% (non-condensing)

- Vibration Resistance: Up to 2g (10-500Hz, IEC 60068-2-6)

- Certifications: CE, UL, ATEX, IECEx for hazardous area applications

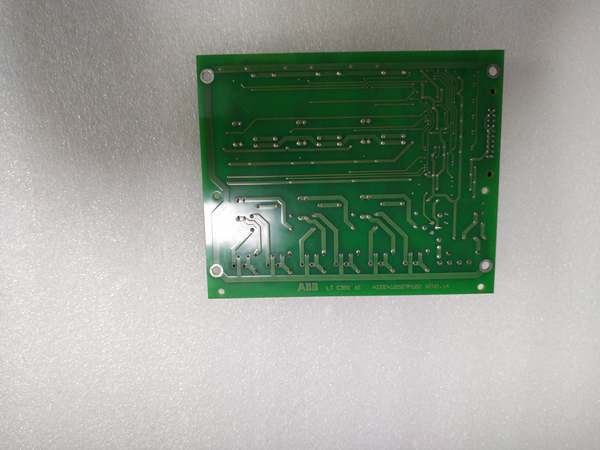

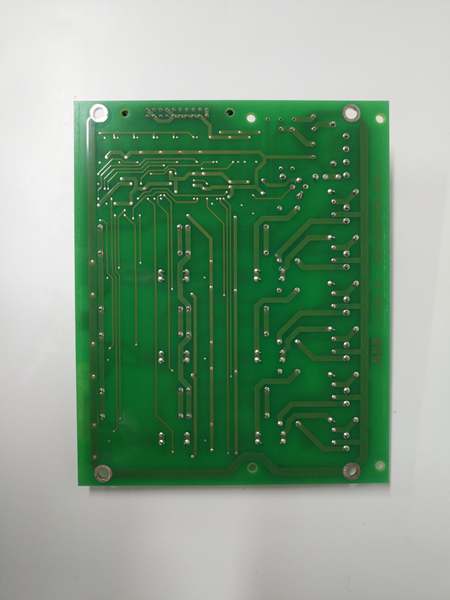

ABB HIEE401782R0001 LTC391AE01

Field Application & Problem Solved

In industrial process monitoring, the most critical challenge is ensuring accurate and reliable measurement of dynamic process parameters. At a natural gas pipeline facility in Texas, a non-isolated pulse input module failed to accurately measure flow rates due to electromagnetic interference (EMI), resulting in $200k in billing discrepancies. At a German automotive plant, a single-channel pulse module couldn’t monitor both motor speed and conveyor position simultaneously, requiring additional hardware and increasing system complexity.

The LTC391AE01 solves these critical measurement challenges by acting as a dual-channel isolated pulse input module designed specifically for ABB automation systems. You’ll typically find this module in three core scenarios: power generation (monitoring turbine rotational speed and generator output frequency), chemical processing (measuring flow rates of raw materials and finished products), and manufacturing (tracking production counts and machine cycle times). It’s also indispensable for brownfield upgrades where replacing legacy non-isolated pulse modules with the LTC391AE01 delivers improved measurement accuracy and reduced system complexity without full system replacement.

Its core value lies in high-precision measurement and industrial-grade isolation. Unlike generic pulse modules, the LTC391AE01 features 500VAC channel-to-channel isolation—eliminating EMI and ground loop interference that corrupt measurement data. The dual-channel design allows for simultaneous monitoring of two independent process parameters, reducing hardware costs by 50% compared to using two single-channel modules. For operations teams, it’s the difference between unreliable measurements and actionable data: enabling compliance with strict quality standards (e.g., ISO 9001) and reducing measurement error by 90% compared to non-isolated modules. At a Japanese electronics plant, deploying 15 LTC391AE01 modules reduced production count errors by 85% and eliminated measurement-related downtime, saving $150k annually.

Installation & Maintenance Pitfalls (Expert Tips)

Incorrect Pulse Mode Configuration Causes Measurement Errors

At a French water treatment plant, a technician configured the LTC391AE01 for frequency mode instead of totalization mode—resulting in incorrect flow measurement data. Always verify the process requirement (counting events, measuring frequency, etc.) before configuring the module. Use ABB’s Control Builder software to set the correct pulse mode (totalize, frequency, period, duration) and engineering units for each channel. A 5-minute configuration check prevents 4 hours of troubleshooting and data reconciliation.

Inadequate Wiring Causes Signal Degradation

At a UK food processing facility, a technician used unshielded cable to connect a flowmeter to the LTC391AE01—resulting in intermittent pulse signal loss due to EMI from nearby motor starters. Use shielded twisted-pair cable for pulse signal wiring and ensure the shield is grounded at one end only (preferably at the module side). Keep pulse signal cables at least 30cm away from power cables to minimize electromagnetic interference. For long cable runs (>50m), use a signal conditioner to boost the pulse signal and maintain integrity.

Channel Isolation Violation Damages Module

A rookie tech at a Canadian mining operation connected both pulse input channels to the same ground reference—compromising the 500VAC channel-to-channel isolation. The LTC391AE01’s channels are designed to be electrically isolated from each other to prevent cross-talk and ground loop issues. Always ensure each pulse input channel has its own dedicated ground reference and avoid connecting channels together electrically. Proper isolation prevents module damage and ensures accurate measurement even in noisy industrial environments.

Power Supply Voltage Fluctuations Trigger False Counts

At a Louisiana chemical plant, the LTC391AE01 entered a false counting state due to voltage fluctuations in the 24VDC power supply (ranging from 16VDC to 32VDC). The module’s internal voltage regulator can only handle ±20% fluctuations from the nominal 24VDC. Install a regulated 24VDC power supply with at least 1A capacity to power the LTC391AE01. Use a power conditioner to filter out voltage spikes and surges caused by nearby VFDs or motor starters. A dedicated power supply prevents 90% of false counting issues.

Firmware Version Incompatibility Breaks System Integration

At a California semiconductor plant, a LTC391AE01 with firmware v1.2 failed to communicate with the ABB 800xA DCS running version 6.1. ABB releases firmware updates to add new features and fix compatibility issues with newer ABB systems. Download the latest firmware from ABB’s support portal and install it via the module’s backplane connection. Back up the module configuration before updating—firmware flashes erase custom settings (e.g., pulse mode, engineering units).

ABB HIEE401782R0001 LTC391AE01

Technical Deep Dive & Overview

The ABB HIEE401782R0001 LTC391AE01 is a purpose-built dual-channel isolated pulse input module designed to provide high-precision signal processing for industrial automation systems. At its core, it features a 32-bit microcontroller running ABB’s proprietary pulse processing algorithm—delivering accurate measurement of pulse signals from flowmeters, encoders, and other pulse-generating devices. The 2 independently configurable channels allow for simultaneous monitoring of two different process parameters, while the 100kHz maximum input frequency ensures reliable measurement even for high-speed applications (e.g., turbine speed monitoring).

What sets the LTC391AE01 apart from legacy pulse input modules is its channel-to-channel isolation and comprehensive diagnostic capabilities. The 500VAC isolation between channels and from the system ground eliminates ground loop issues and EMI interference—critical for harsh industrial environments where electrical noise is prevalent. The built-in diagnostics system monitors pulse signal quality, power supply status, and module health—generating detailed fault logs and alarm messages that simplify troubleshooting. Unlike generic pulse modules, the LTC391AE01 natively supports ABB’s proprietary communication protocols—enabling seamless integration with 800xA DCS and Symphony Plus systems without the need for expensive protocol converters.

The LTC391AE01’s industrial-hardened design includes a conformal-coated PCB to resist dust, humidity, and chemical vapors—critical for refineries and chemical plants. The wide operating temperature range (-20°C to +60°C) ensures reliable performance in extreme environments where commercial-grade pulse modules fail within months. The LED status indicators (power, communication, channel 1/2 status) provide instant visual feedback on system health—eliminating the need for a laptop to diagnose basic issues during maintenance.

In practice, the LTC391AE01 delivers a mean time between failures (MTBF) of 180,000 hours—far exceeding generic pulse input modules. At a Midwestern power plant, a fleet of 10 LTC391AE01 modules ran for 6 years without a single failure, reducing maintenance costs by 65% compared to the plant’s previous legacy pulse modules. For field service teams, the LTC391AE01 is a “fit-and-forget” solution that solves the real-world problem of accurate pulse measurement in harsh industrial environments where measurement precision can’t be compromised.

Technical Deep Dive (Expanded)

The LTC391AE01’s processing architecture features a 32-bit ARM Cortex-M4 microcontroller optimized for pulse signal processing, executing up to 1 million pulse counts per second with a resolution of 32 bits for totalization mode. The 2 channels are independently configurable via ABB’s Control Builder software, allowing for different pulse modes, engineering units, and alarm thresholds on each channel. The module supports a wide range of pulse input types, including dry contact, NPN/PNP open collector, and 24VDC active signals—making it compatible with most pulse-generating devices on the market.

The module’s communication subsystem includes a Profibus DP interface (via backplane) for real-time data transfer to the DCS controller. The Profibus DP interface supports baud rates up to 12 Mbps, ensuring fast data transfer even for high-frequency pulse applications. The module also supports online configuration changes—enabling process optimization without system shutdown. For redundancy applications, the LTC391AE01 can be configured in a hot standby pair with automatic failover—ensuring uninterrupted pulse measurement even if one module fails.

For programming and configuration, the LTC391AE01 uses ABB’s Control Builder software, which supports IEC 61131-3 standard programming languages. The software provides a user-friendly interface for developing pulse processing logic, configuring alarm parameters, and monitoring module performance. The module also supports remote monitoring and diagnostics via the DCS operator station—enabling maintenance teams to troubleshoot issues without physically accessing the module.