Description

Detailed parameter table

| Parameter name | Parameter value |

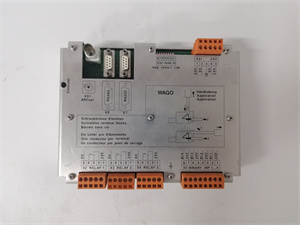

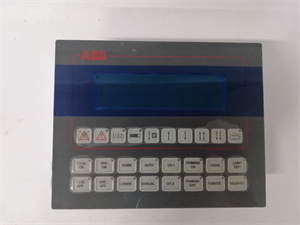

| Product model | HIEE200130R0002 AFC094AE02 |

| Manufacturer | ABB |

| Product category | Analog output module (Advant OCS system) |

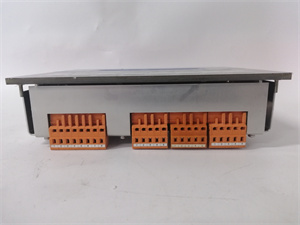

| Output channels | 4 isolated analog outputs |

| Output type | 4-20 mA DC (configurable to 0-20 mA DC) |

| Resolution | 16-bit |

| Accuracy | ±0.1% of full scale |

| Output load range | 0-750 Ω |

| Isolation | 2500 VAC (channel to backplane, channel to channel) |

| Update rate | 100 ms per channel |

| Operating voltage | 24 VDC ±10% |

| Power consumption | Max 6 W |

| Operating temperature | 0°C to 60°C |

| Protection rating | IP20 |

| Dimensions | 100mm × 80mm × 60mm |

| Weight | 0.35kg |

| Certifications | IEC 61131-2, CE, UL, CSA |

| Mounting type | DIN rail (35mm) with backplane connection |

ABB HIEE200130R0002 AFC094AE02

Product introduction

The ABB HIEE200130R0002 AFC094AE02 is a high-precision analog output module designed for seamless integration with ABB’s Advant Open Control System (OCS), serving as a critical interface for converting digital control signals from the system into proportional analog outputs. This module is engineered to deliver reliable and accurate control signals to a wide range of field devices, making it an essential component in process automation across industries such as chemical processing, power generation, and water treatment.

Featuring 4 isolated channels, each configurable for 4-20 mA or 0-20 mA DC output, the ABB HIEE200130R0002 AFC094AE02 provides flexible control capabilities for actuators, valves, variable speed drives, and other analog-controlled equipment. Its 16-bit resolution and ±0.1% accuracy ensure precise signal delivery, enabling tight control over critical process variables such as flow, pressure, and temperature.

Within the Advant OCS architecture, the ABB HIEE200130R0002 AFC094AE02 acts as a bridge between the system’s digital control logic and analog field devices. Its robust isolation design protects both the control system and field equipment from electrical noise, ground loops, and voltage transients, ensuring stable operation in harsh industrial environments. Whether deployed in continuous process plants or batch production facilities, this module delivers consistent performance for maintaining process efficiency and product quality.

Core advantages and technical highlights

High-precision output: The ABB HIEE200130R0002 AFC094AE02 achieves 16-bit resolution and ±0.1% accuracy, ensuring that even small changes in the control signal are accurately translated to the field device. This level of precision is critical for applications such as pharmaceutical manufacturing, where precise control of mixing ratios or temperature gradients directly impacts product quality. For example, it can maintain a flow rate within ±0.02 m³/h for a 0-10 m³/h process loop, ensuring compliance with strict process tolerances.

Channel-level isolation: Each of the 4 output channels features 2500 VAC isolation from the backplane and from other channels, eliminating cross-talk and protecting against ground loops. This isolation is particularly valuable in plants with distributed field devices, where potential differences between equipment grounds could otherwise distort control signals. It also enhances system safety by preventing high-voltage transients from propagating through the control system.

Flexible output configuration: Each channel can be individually configured for 4-20 mA or 0-20 mA operation via software, providing compatibility with a wide range of field devices without requiring hardware modifications. This flexibility allows the module to control both two-wire (4-20 mA) and four-wire (0-20 mA) actuators, reducing inventory complexity and simplifying system design. Configuration is performed through ABB’s Control Builder software, with settings stored in non-volatile memory to retain configurations during power cycles.

Robust load handling: The module supports output loads from 0 to 750 Ω, enabling direct connection to long cable runs and multiple field devices in series. This capability is particularly useful in large-scale facilities, where control valves may be located hundreds of meters from the control cabinet. The outputs include overcurrent protection, automatically limiting current to 30 mA to prevent damage to the module or field equipment in case of a short circuit.

Fast update rates: With a 100 ms per channel update rate, the ABB HIEE200130R0002 AFC094AE02 ensures rapid response to changes in the control signal, making it suitable for dynamic processes that require quick adjustments. For example, in a pressure control loop, the module can update the valve position within 100 ms of a setpoint change, minimizing overshoot and maintaining stable process conditions.

Typical application scenarios

In chemical processing plants, the ABB HIEE200130R0002 AFC094AE02 controls variable speed drives for pumps and agitators, adjusting their speed via 4-20 mA signals to maintain precise flow rates and mixing intensities. Its channel isolation prevents interference between corrosive chemical dosing loops and other process lines, while its high accuracy ensures that reagent additions are metered within ±0.1% of the target, reducing waste and ensuring product consistency.

Within power generation facilities, the module regulates control valves in steam and water circuits, using 4-20 mA signals to adjust valve position and maintain optimal pressure and temperature conditions. Its fast update rate is critical for load-following applications, where the system must quickly respond to changes in grid demand. The module’s robust load handling allows it to drive valves located in remote parts of the plant, even over long cable runs.

In water and wastewater treatment facilities, the ABB HIEE200130R0002 AFC094AE02 controls chemical dosing pumps, adjusting the 4-20 mA signal to vary the pump stroke and maintain precise chemical concentrations. Its accuracy ensures that disinfectant levels (e.g., chlorine) are kept within regulatory limits, while its isolation protects the control system from electrical noise generated by wastewater pumps and aeration systems.

In food and beverage production, the module regulates temperature control valves and flow meters, using 0-20 mA signals to adjust heating elements and maintain consistent product quality. Its high precision ensures that pasteurization temperatures are held within ±0.1°C, meeting food safety standards, while its compact design fits easily in the control panels of space-constrained processing lines.

ABB HIEE200130R0002 AFC094AE02

Related model recommendations

ABB HIEE200129R0002 AFC093AE02: A 4-channel analog input module that pairs with the ABB HIEE200130R0002 AFC094AE02, providing measurement data for closed-loop control.

ABB Advant Controller 450: The main process controller in the Advant OCS system that generates digital control signals for the ABB HIEE200130R0002 AFC094AE02.

ABB TU810V1: A termination unit that simplifies wiring for the ABB HIEE200130R0002 AFC094AE02, providing surge protection and easy field connections.

ABB CI801 3BSE022369R1: A communication interface that connects the Advant OCS system (with ABB HIEE200130R0002 AFC094AE02) to Ethernet-based networks.

ABB V18345-1010521001: A 4-20 mA positioner for control valves, designed to work with the ABB HIEE200130R0002 AFC094AE02 for precise flow control.

ABB 800xA Extension: Software that integrates the ABB HIEE200130R0002 AFC094AE02 into ABB’s 800xA DCS, enabling advanced visualization and control.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the ABB HIEE200130R0002 AFC094AE02, ensure the 35mm DIN rail is securely mounted and grounded in a clean, dry control cabinet. Verify the ambient temperature is within 0°C to 60°C and humidity is below 95% RH (non-condensing). Required tools include a torque screwdriver (0.5-0.8 Nm), wire strippers, and a multimeter. Use shielded twisted-pair cables (0.5-1.0 mm²) for analog connections, with shields grounded at both ends to minimize noise. Ensure the total load per channel does not exceed 750 Ω.

Commissioning steps: After physical installation, power on the system and launch ABB’s Control Builder software to configure channel parameters (4-20 mA or 0-20 mA) and scaling (e.g., engineering units like valve position % or flow rate). Calibrate each channel using a precision current meter, verifying that the output matches the setpoint within ±0.1% of full scale. Test communication with the Advant Controller to ensure control signals are transmitted correctly, and configure fault alarms for open circuits or overcurrent conditions.

Maintenance suggestions: Inspect the ABB HIEE200130R0002 AFC094AE02 quarterly for loose connections, dust accumulation, or signs of corrosion; clean with compressed air if necessary. Verify output accuracy annually using a certified calibration tool, adjusting offsets if needed. Monitor module status via the Advant OCS—check for communication errors or channel faults. If a channel fails, isolate the issue by disconnecting the field device and testing with a known load; replace the module with an ABB-approved unit if faults persist to maintain control integrity.

Service and guarantee commitment

The ABB HIEE200130R0002 AFC094AE02 comes with a 36-month warranty from the date of installation, covering manufacturing defects and ensuring compliance with published accuracy specifications. ABB guarantees replacement of faulty modules within 72 hours for critical applications, minimizing downtime in process control systems.

Technical support includes access to ABB’s global team of automation engineers, available for assistance with configuration, calibration, and troubleshooting. Online resources include detailed wiring diagrams, calibration procedures, and compatibility charts specific to the Advant OCS system. Customers can opt for extended service contracts offering annual preventive maintenance, calibration services, and on-site support, ensuring the module delivers reliable performance throughout its 10-year design lifespan.