Description

Key Technical Specifications

- Model Number: GMKP2800-32IBY

- Manufacturer: ABB Power Products Division

- Rated Voltage: 12kV (max 12.7kV)

- Rated Current: 2500A (continuous)

- Short-Circuit Breaking Capacity (Isc): 31.5kA (3s)

- Short-Circuit Making Capacity: 80kA (peak)

- Number of Poles: 3 (3-phase)

- Arc Quenching Medium: Vacuum (ceramic vacuum interrupters)

- Operating Mechanism: Spring-operated (manual/electric charging, 24VDC/110VDC/220VAC control)

- Mechanical Life: 30,000 operations (standard), 60,000 operations (extended)

- Electrical Life: 10,000 operations at rated current; 300 operations at 31.5kA

- Protection Class: IP54 (enclosure); IP67 (vacuum interrupter contacts)

- Operating Temperature: -25°C to +40°C (ambient, derate above 35°C)

- Mounting Type: Fixed or withdrawable (for switchgear cubicles, IEC 62271-200 compliant)

- Control Voltage: 24VDC (standard), 110VDC/220VAC (optional)

- Weight: 185kg (fixed), 210kg (withdrawable)

- Diagnostic Features: Mechanical wear monitoring, contact wear indication, operation counter, trip/close status feedback

ABB MEMORYCA

Field Application & Problem Solved

In medium-voltage power distribution (12kV) for industrial facilities—power plants, refineries, chemical plants—the biggest challenge is reliable fault interruption and load switching while minimizing downtime and maintenance. Legacy oil or air-blast circuit breakers require frequent maintenance (oil replacement, air system checks) and pose environmental risks, while low-quality vacuum breakers suffer from premature contact wear or mechanism failure. At a Texas refinery, outdated oil circuit breakers caused 3 unplanned distribution outages in a year due to oil leakage and arc quenching inefficiencies, costing $500k in lost production.

This vacuum circuit breaker solves those pain points. You’ll find it in power plant auxiliary distribution systems (feeding pumps, fans, compressors), refinery process unit substations, and chemical plant medium-voltage switchgear—protecting critical equipment from short circuits and overloads. It’s the workhorse for industrial MV distribution where low maintenance and high reliability are non-negotiable: its vacuum arc quenching technology eliminates oil/air-related failures, while the spring-operated mechanism ensures consistent trip/close performance. In a Midwest coal-fired power plant, retrofitting with GMKP2800-32IBY reduced maintenance costs by 70% and eliminated fault-related outages over 4 years.

Its core value is rugged reliability in harsh industrial environments. Unlike oil breakers, it has no environmental hazards or leakage risks; unlike air-blast breakers, it requires no compressed air system. The vacuum interrupters provide fast arc quenching (≤20ms) even at high fault currents, limiting equipment damage. For field teams, this means fewer maintenance hours (annual inspections vs. quarterly for oil breakers), faster fault recovery, and confidence that the breaker will operate when needed—critical for protecting expensive MV equipment and avoiding production downtime.

Installation & Maintenance Pitfalls (Expert Tips)

- Improper Mechanism Lubrication Causes Premature Failure: Rookies often use generic grease instead of ABB-specified lubricant (ABB Part No. 1SCA022516R0001) on the spring mechanism. I saw this at a chemical plant where the breaker failed to close after 6 months—generic grease hardened in cold temperatures, jamming the mechanism. Use only ABB-approved lubricant, apply a thin film (0.5mm) to pivot points, and re-lubricate every 10,000 operations.

- Busbar Torque Must Match Specifications: Under-torquing busbar connections leads to hot spots and contact resistance; over-torquing damages conductor lugs. A Pennsylvania power plant had a busbar connection melt due to under-torquing—use a calibrated torque wrench set to 45 N·m for 12kV copper busbars (per IEC 61439-1). Verify torque after initial installation and recheck after 6 months of operation.

- Ignore Vacuum Interrupter Integrity at Your Peril: Vacuum interrupters can develop leaks over time, reducing arc quenching capability. Technicians often skip contact resistance and vacuum integrity tests. Use a micro-ohmmeter to measure contact resistance (should be ≤50μΩ per pole) and a vacuum tester to check for leaks annually. A Florida refinery avoided a catastrophic short-circuit by replacing a breaker with 150μΩ contact resistance before it failed.

- Poor Grounding Compromises Protection: The breaker’s frame ground must be connected to the facility’s main ground grid with a minimum 35mm² copper conductor. A rookie at a paper mill used a 16mm² conductor, leading to improper fault current dissipation during a short circuit—damaging the breaker’s control electronics. Ensure frame ground resistance is ≤1Ω, and verify with a ground resistance tester.

- Mechanical Conditioning Before Commissioning: Skipping pre-commissioning mechanism cycling causes inconsistent performance. At a power plant, the breaker tripped unpredictably because the spring mechanism wasn’t conditioned—cycle the breaker manually 20 times (open/close) before energizing to seat contacts and break in the mechanism. Document cycle count and contact resistance post-conditioning.

ABB MEMORYCA

Technical Deep Dive & Overview

The GMKP2800-32IBY is a 3-pole, spring-operated vacuum circuit breaker designed for 12kV medium-voltage power distribution, part of ABB’s GMKP series renowned for industrial ruggedness. It acts as the primary protection device for MV equipment, interrupting short circuits and switching loads while providing status feedback for substation automation.

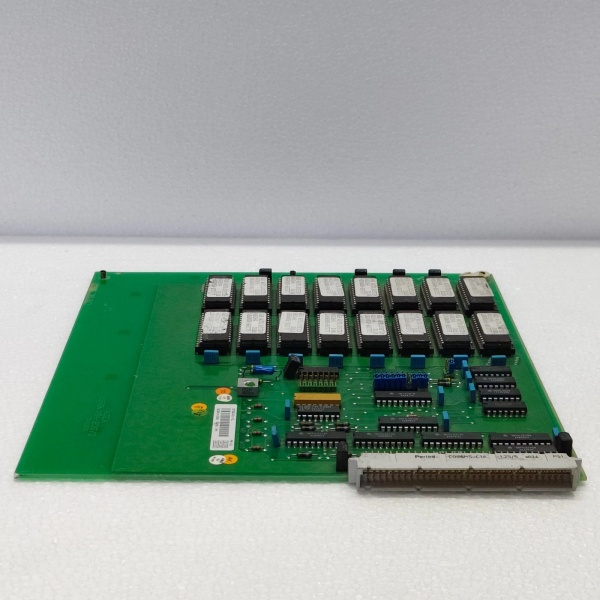

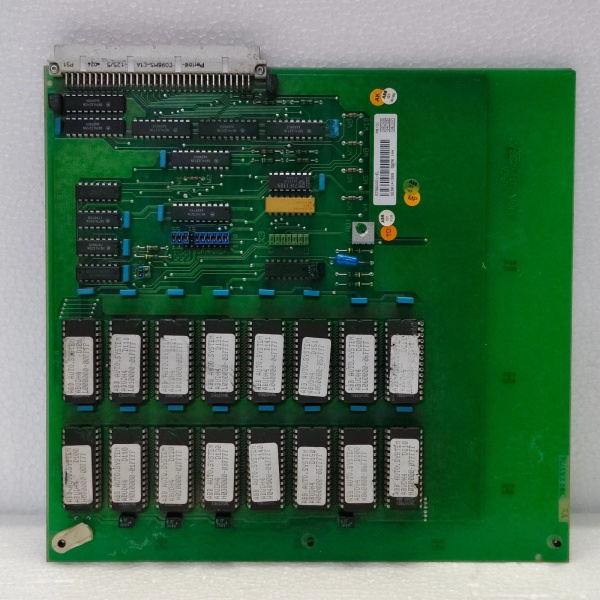

At its core are three ceramic vacuum interrupters (one per pole), each containing two contacts sealed in a high-vacuum (10⁻⁶ mbar) environment. When a fault occurs, the spring mechanism rapidly separates the contacts (opening time ≤60ms), and the vacuum quenches the arc—eliminating the need for oil or compressed air. The vacuum interrupters have a long service life: contact wear is minimal (≤0.1mm per 1000 operations), ensuring consistent performance over 10,000 electrical operations.

The spring-operated mechanism is charged manually (for emergency) or electrically (standard), storing energy in torsion springs for fast, repeatable trip/close actions. It includes mechanical interlocks (preventing open/close under incorrect conditions) and an operation counter to track maintenance intervals. The breaker’s control electronics integrate with substation automation systems (via auxiliary contacts or optional IEC 61850 communication) to provide real-time status (open/closed, fault trip, mechanism health) for remote monitoring.

What makes it field-tough is its industrial design: weatherproof IP54 enclosure (resisting dust and water jets), wide operating temperature range (-25°C to +40°C), and vibration tolerance up to 2g. The vacuum interrupters are hermetically sealed, protecting against humidity and chemical vapors common in refineries and power plants. Unlike legacy breakers, it requires no routine fluid replacement or complex system checks—only annual inspections of contacts, mechanism, and grounding. This is the breaker you install when you need reliable, low-maintenance protection for critical medium-voltage distribution systems.