Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | GCC960C103 |

| Manufacturer | ABB |

| Product category | Communication gateway (Industrial IT system) |

| Supported protocols | PROFINET, Ethernet/IP, Modbus TCP/IP, Profibus DP |

| Ethernet ports | 4 x 10/100/1000 Mbps (gigabit, redundant) |

| Serial ports | 2 x RS-485 (for Profibus DP/Modbus RTU) |

| Data transfer rate | Up to 1 Gbps (Ethernet); 12 Mbps (Profibus DP) |

| Maximum connected devices | 256 (total across all protocols) |

| Operating temperature | -10°C to 60°C |

| Protection rating | IP30 |

| Dimensions | 140mm × 180mm × 100mm |

| Weight | 1.2kg |

| Certifications | IEC 61131-2, CE, UL, ATEX |

| Power supply | 24 VDC ±10%, 15 W max |

| Mounting type | DIN rail (35mm) or panel mount |

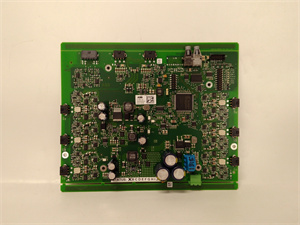

ABB GCC960C103

Product introduction

The ABB GCC960C103 is a high-performance communication gateway designed to facilitate seamless data exchange between diverse industrial protocols in complex automation systems. As a key component of ABB’s Industrial IT portfolio, this gateway acts as a universal translator, enabling interoperability between legacy and modern devices across manufacturing, process, and infrastructure sectors.

Equipped with multiple communication interfaces and support for industry-standard protocols, the ABB GCC960C103 breaks down connectivity barriers between PROFINET controllers, Ethernet/IP devices, Modbus sensors, and Profibus DP networks. Its gigabit Ethernet ports ensure high-speed data transmission, while redundant design elements maximize system availability—critical for mission-critical applications where communication downtime could disrupt operations.

Within industrial ecosystems, the ABB GCC960C103 serves as a central communication hub, consolidating data from disparate systems into a unified stream for monitoring and control. This integration capability reduces the need for multiple protocol-specific gateways, simplifies network architecture, and enhances visibility across the entire automation landscape, ultimately improving operational efficiency and decision-making.

Core advantages and technical highlights

Multi-protocol translation: The ABB GCC960C103 natively supports PROFINET, Ethernet/IP, Modbus TCP/IP, and Profibus DP, enabling bidirectional data flow between otherwise incompatible systems. This eliminates the need for custom software bridges or protocol converters, reducing integration costs by up to 40% compared to multi-gateway setups. For example, it can seamlessly translate production data from a PROFINET-enabled robotic cell to an Ethernet/IP-based SCADA system and vice versa.

Redundant high-speed connectivity: With four gigabit Ethernet ports (configurable as two redundant pairs) and dual RS-485 ports, the ABB GCC960C103 ensures uninterrupted communication. Redundant network paths automatically switch over in <50ms if a primary link fails, making it ideal for critical applications like power plant control systems or pharmaceutical batch processing lines where data loss is unacceptable.

Scalable device management: Supporting up to 256 connected devices, the ABB GCC960C103 scales easily with growing automation systems. Its intuitive web-based configuration interface allows engineers to map data points, set up message routing, and monitor network health without specialized programming skills. This scalability makes it suitable for applications ranging from small manufacturing cells to large distributed facilities with multiple process areas.

Industrial-grade durability: Built to withstand harsh environments, the ABB GCC960C103 operates reliably in temperatures from -10°C to 60°C and tolerates vibration up to 5g (per IEC 60068-2-6). Its IP30 rating protects against dust ingress, while robust component selection ensures a mean time between failures (MTBF) exceeding 100,000 hours—critical for deployment in unconditioned industrial spaces like factory floors or outdoor equipment enclosures.

Typical application scenarios

In automotive assembly plants, the ABB GCC960C103 integrates islanded production systems: translating data between PROFINET robots, Ethernet/IP conveyor controls, and Modbus energy meters. This allows the central MES system to monitor overall equipment effectiveness (OEE) across diverse machinery, identify bottlenecks, and optimize energy usage—all in real time. The gateway’s redundancy ensures production data collection continues even if a network segment fails.

Within water treatment facilities, the ABB GCC960C103 connects legacy Profibus DP pressure transmitters and modern Ethernet/IP valve actuators to a Modbus-based SCADA system. It consolidates data from distributed pump stations and filtration units, providing operators with a unified view of the entire water distribution network. Its wide temperature tolerance ensures reliable operation in both climate-controlled control rooms and outdoor pump enclosures.

In food and beverage processing, the ABB GCC960C103 bridges batch control systems (Ethernet/IP) with legacy filling line sensors (Profibus DP) and quality monitoring devices (Modbus TCP). It enables synchronized data collection during production runs, ensuring compliance with traceability requirements by linking process parameters to batch records. The gateway’s ATEX certification also allows deployment in hazardous areas such as alcohol bottling lines.

ABB GCC960C103

Related model recommendations

ABB GCC961C103: A compact variant of the ABB GCC960C103 with 2 Ethernet ports, designed for smaller-scale protocol translation needs.

ABB AC800M PM864K01: A controller that integrates with the ABB GCC960C103 to process translated data and execute control logic across multi-protocol networks.

ABB CI854A 3BSE022469R1: A Profibus DP interface module that extends the network reach of the ABB GCC960C103 in large distributed systems.

ABB 800xA DCS: A distributed control system that utilizes data from the ABB GCC960C103 for advanced process visualization and control.

ABB TB850 3BSE008519R1: A terminal block accessory for the ABB GCC960C103 that simplifies wiring and provides surge protection for serial connections.

ABB CP600 HMI: A human-machine interface that displays unified data from the ABB GCC960C103, enabling operators to monitor multi-protocol systems in real time.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the ABB GCC960C103, ensure the mounting surface (35mm DIN rail or panel) is securely grounded and free from excessive vibration. Verify the ambient temperature range (-10°C to 60°C) and humidity (5-95% RH non-condensing) are within specifications. Required tools include a torque screwdriver (0.6-1.0 Nm), wire strippers, and a network cable tester. Use shielded Cat6 Ethernet cables for gigabit connections and twisted-pair cables for RS-485 links, with shields grounded at both ends to minimize interference.

Maintenance suggestions: Inspect the ABB GCC960C103 quarterly for loose connections, dust accumulation, or corrosion. Clean ventilation slots with compressed air to prevent overheating. Monitor network health via the gateway’s web interface, checking for port errors, high latency, or device disconnections. Update firmware annually using ABB’s official software to ensure compatibility with new protocol versions. Backup configuration settings monthly to a secure location. If a hardware fault occurs, replace with an ABB-approved spare to maintain system integrity and certifications.

Service and guarantee commitment

The ABB GCC960C103 is backed by a 36-month warranty from the date of installation, covering manufacturing defects and ensuring compliance with published performance standards. ABB guarantees replacement of faulty units within 48 hours for critical applications, minimizing downtime in interconnected automation systems.

Technical support includes access to ABB’s global team of industrial communication specialists, available 24/7 for configuration assistance and troubleshooting. Online resources include detailed protocol mapping guides, firmware updates, and compatibility matrices. Customers can opt for extended service contracts that include annual network audits, proactive firmware management, and on-site support, ensuring the ABB GCC960C103 delivers reliable protocol translation throughout its 10-year design lifespan.