Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

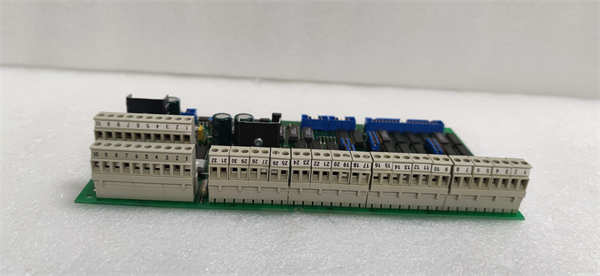

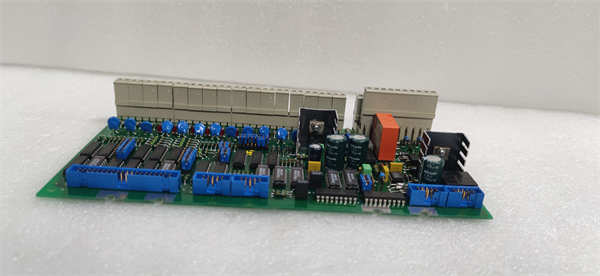

| Product Model | ABB DSTXW110 |

| Manufacturer | ABB |

| Product Category | Terminal Board / Signal Conditioning Unit |

| Compatible I/O Modules | AI810, AI820, AO910, AO920 Series |

| Channels Supported | 16 channels (configurable per slot) |

| Terminal Type | Screw Clamp (0.2–2.5 mm² / AWG 24-12) |

| Isolation Voltage | 500 V AC (field-to-system) |

| HART Support | Yes (pass-through for HART® 7) |

| Surge Protection | 20 V (field inputs), 60 V (communication lines) |

| Fuse Protection | Per channel (replaceable 250 mA fuses) |

| Operating Temperature | -40°C to +85°C |

| Installation | DIN Rail (TS35) or direct mounting |

| Safety Certification | IEC 61131-2, ATEX Cat. 3 |

ABB DSTXW110

Product Introduction

The ABB DSTXW110 is a specialized termination board designed for ABB’s Symphony™ Plus distributed control system (DCS). It serves as the critical interface between field instruments and ABB’s analog I/O modules (e.g., AI810, AO910), providing secure, noise-resistant signal routing and conditioning. Engineered for high-density installations, this terminal board consolidates wiring for up to 16 channels while integrating surge suppression, fuse protection, and HART® signal pass-through capabilities.

As a foundational component of ABB’s S+ I/O architecture, the ABB DSTXW110 ensures signal integrity from field devices to control processors. It translates raw sensor/actuator connections into standardized, isolated inputs for upstream modules, mitigating ground loops and electromagnetic interference (EMI). The ABB DSTXW110 is indispensable for maintaining data accuracy in safety-critical loops, reducing wiring complexity, and enabling rapid fault isolation in large-scale industrial automation systems.

Core Advantages and Technical Highlights

The ABB DSTXW110 delivers robust signal management and operational resilience:

Enhanced Signal Integrity: Integrated EMI/RFI filtering and 500 V isolation eliminate noise from VFDs, motors, and power lines. Gold-plated contacts minimize contact resistance drift (<2 mΩ), ensuring long-term measurement stability for sensitive analog signals (e.g., RTD thermocouples).

HART® Signal Preservation: Dedicated HART® signal routing preserves digital communication superimposed on 4–20 mA loops. This allows asset management tools to interrogate field devices (e.g., pressure transmitters) without disconnecting wires or compromising control continuity.

Modular Safety Design: Replaceable 250 mA fuses per channel protect downstream I/O modules from overcurrent events. Integrated transient voltage suppressors (TVS diodes) clamp surges up to 20 V on inputs, preventing damage from lightning or inductive loads.

Tool-Free Maintenance: Front-accessible fuses and screw terminals enable rapid troubleshooting. Channel status LEDs (green/red) visually identify open circuits or blown fuses, reducing mean-time-to-repair (MTTR) by 40%.

Universal Compatibility: Supports mixed-signal configurations within one unit (e.g., combining AI810 temperature inputs and AO910 valve outputs). Backplane connectors auto-adapt to ABB’s S+ I/O cards, eliminating manual jumpers.

Extreme Environment Readiness: Operates in -40°C to +85°C environments with 100 g shock resistance. Corrosion-resistant tin-nickel plating withstands salty/humid atmospheres in offshore or coastal sites.

Typical Application Scenarios

The ABB DSTXW110 excels in centralized I/O management for critical infrastructure:

Power Plant Instrumentation Cabinets: Terminates 200+ field cables from boiler pressure transmitters, turbine vibration sensors, and emission analyzers. The ABB DSTXW110’s fused protection prevents single-channel failures from disrupting entire control racks during grid fluctuations.

Oil & Gas Tank Farms: Consolidates level radar and temperature signals from storage tanks. HART® pass-through enables remote calibration of Rosemount transmitters without hot-work permits in hazardous (Zone 1) areas.

Pharmaceutical Batch Systems: Routes signals from CIP (clean-in-place) flowmeters and bioreactor pH probes. Gold-plated contacts prevent micro-arcing that could compromise SIL 2 loops during steam sterilization cycles.

Water Pumping Stations: Interfaces pump discharge pressure switches and valve feedbacks. TVS diodes protect against voltage spikes from motor starts, while IP20-rated housing resists condensation.

Related Model Recommendations

ABB AI810: 16-channel analog input module; pairs with DSTXW110 for temperature/pressure monitoring.

ABB AO920: High-resolution analog output module; drives actuators via DSTXW110’s fused outputs.

ABB DSDP-01: Digital input processor; interfaces with DSTXW110 for contact status monitoring.

ABB HTTA-01: S+ I/O rack chassis; houses 8x DSTXW110 boards in redundant configurations.

ABB NINR-21: Network redundancy module; ensures uninterrupted communication to DSTXW110-equipped racks.

ABB CI867: Ethernet/IP adapter; enables DSTXW110-terminated signals to integrate with Rockwell PLCs.

ABB DSTXW110

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Mount ABB DSTXW110 on 35 mm DIN rail (TS35) within HTTA-series rack. Ensure ambient temperature <85°C and clearance ≥50 mm above/below for airflow. Use copper conductors only (max 2.5 mm²). Strip wires to 8±0.5 mm. Disconnect field power before wiring.

Maintenance Suggestions: Quarterly, verify terminal torque (0.6 N·m) and inspect for oxidation. Annually, test fuse continuity and TVS diode function (using 15 V pulse generator). Replace blown fuses with ABB-specified 250 mA types only. Monitor channel LEDs via Control Builder MT: solid red indicates open circuit. Clean dust with dry air (no solvents). For HART® loops, verify communication impedance >250 Ω.

Service and Guarantee Commitment

ABB provides an 18-month warranty for the ABB DSTXW110, covering material and manufacturing defects. Global technical support includes free firmware updates and 24/7 access to ABB’s Ability™ Collaborative Operations Centers for troubleshooting documentation. On-site commissioning services ensure proper grounding and signal routing validation. The product’s design complies with ATEX, IECEx, and IEC 61131-2 standards, with certificates supplied. ABB guarantees spare parts availability for 15+ years post-discontinuation and offers lifecycle extension services for legacy Harmony systems.