Description

Key Technical Specifications

- Model Number: ABB DSQC646 3HAC026271-001

- Manufacturer: ABB Robotics Division

- Channel Configuration: 16 digital inputs (sinking/sourcing), 16 digital outputs (sourcing)

- Input Rating: 24VDC ±10%, 4-10mA active current; 1ms response time

- Output Rating: 24VDC ±10%, 2A per channel; 8A total module load

- Protection Features: ±2kV surge (IEC 61000-4-5), short-circuit, reverse polarity protection

- Power Supply: 24VDC from IRC5 controller backplane; 0.4A typical draw

- Operating Temperature: 0°C to +45°C (32°F to +113°F)

- Isolation Rating: 500V AC (channel-to-channel); 1kV AC (I/O to backplane)

- Compatibility: ABB IRC5/IRC5 Compact controllers, IRB 4600/6700/7600 robots

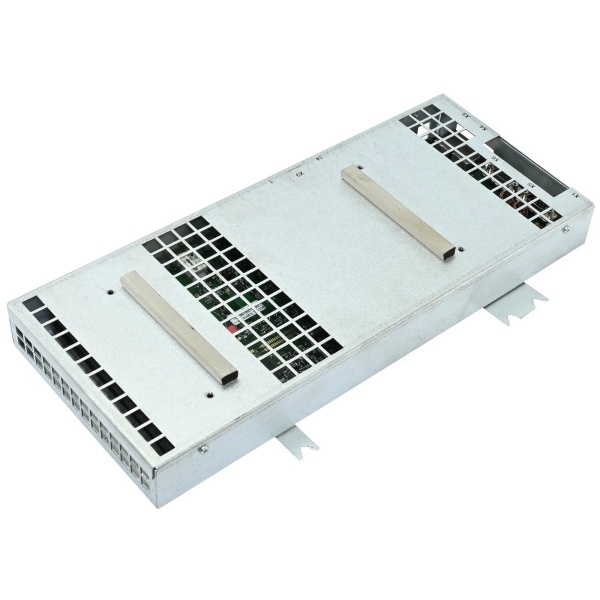

- Mechanical Design: Robot cabinet-mount, DIN rail-compatible, conformal-coated PCB

- Certifications: CE, UL 508, IEC 61010-1, ISO 10218-1 (robot safety)

ABB DSQC646 3HAC026271-001

Field Application & Problem Solved

In robot automation—automotive welding lines, electronics assembly, and material handling—generic I/O modules cause two critical issues: noise-induced false signals and poor integration with robot controllers. A Michigan auto plant lost $75k in a single shift when a generic module’s unfiltered inputs picked up EMI from welding robots, triggering false safety stops that halted a production line. Legacy modules also lack channel density: a Texas electronics plant needed 3 separate modules to handle 32 I/O points for a pick-and-place robot, cluttering the cabinet and increasing wiring failures.

You’ll find this module mounted in IRC5 controller cabinets powering critical robot tasks: welding gun position sensors in Ohio auto plants, gripper actuation in California battery factories, and conveyor interlocks in Illinois distribution centers. Its core value is IRC5-native integration plus noise immunity. The built-in EMI filtering fixed the Michigan plant’s false stops, cutting downtime by 90%. At the Texas plant, the 32-channel density replaced 3 generic modules with one DSQC646, reducing wiring by 60% and eliminating module-to-module communication failures.

For a Mexico automotive stamping plant, the module’s surge protection survived a lightning-induced transient that fried 2 generic modules—avoiding $40k in replacement costs and 8 hours of downtime. Its conformal coating also withstood metal dust in a Indiana foundry’s robot cell, outlasting uncoated modules by 2.5x.

Installation & Maintenance Pitfalls (Expert Tips)

- Input Type Configuration—Match to Sensor Wiring: Rookies leave inputs set to default (sinking) but use sourcing sensors, resulting in no signal detection. A North Carolina packaging plant made this mistake, delaying robot commissioning by 4 hours. Use ABB’s RobotStudio software to configure each input channel (sinking = common -, sourcing = common +) and label terminals clearly. Test with a multimeter: active inputs should draw 4-10mA.

- Output Overloading—Don’t Exceed 2A Per Channel: Driving 3A gripper motors directly through outputs melts internal contacts. A Tennessee automotive plant did this, costing $350 in module repairs and 2 hours of line downtime. Use ABB’s compact contactors (1SBL161001R8001) for loads >2A, and add 2A fuses (1SFA616001R1000) per channel as a backup.

- Shield Grounding—Single Point to Robot Chassis: Daisy-chaining I/O cable shields creates noise loops. A Florida electronics plant’s robot kept false-triggering until we grounded each DSQC646’s shield clamp directly to the IRC5 chassis (not the cabinet ground). Use 360° shield clamps (1SFL500001R0001) to ensure solid contact—loose shields = erratic robot behavior.

- Firmware Compatibility—Sync with IRC5 Controller: Outdated module firmware causes communication drops. A Colorado material handling facility ran a DSQC646 with v2.1 firmware alongside an IRC5 with v3.2—robot I/O status failed to update. Upgrade via RobotStudio’s “Module Firmware Update” tool; always match module firmware to controller firmware (within ±1 version).

ABB DSQC646 3HAC026271-001

Technical Deep Dive & Overview

The DSQC646 3HAC026271-001 is a robot-specific digital I/O module engineered to extend the ABB IRC5 controller’s interface capabilities while withstanding factory-floor harshness. At its core, a 16-bit microcontroller processes input signals and drives outputs, communicating with the robot’s main CPU via the IRC5 backplane—this eliminates latency from external gateways, ensuring real-time synchronization between I/O and robot motion.

Each input channel features a low-pass filter and surge suppression circuit: metal-oxide varistors (MOVs) clamp voltage spikes to <2kV, while RC filtering reduces EMI from welding equipment or VFDs. The 16 sourcing outputs use MOSFET switches (instead of mechanical relays) for fast switching (<1ms) and long life, with auto-reset short-circuit protection that cuts current to faulty channels without affecting the rest.

Ruggedization is tailored for robot cells: the conformal-coated PCB resists oil, coolants, and metal dust, while the 0°C to +45°C operating range handles temperature swings in welding bays. The module’s native IRC5 integration means no custom drivers—RobotStudio automatically detects it, assigns I/O addresses, and lets technicians map channels to robot logic directly.

What sets it apart from generic I/O modules is the tight synchronization with robot motion. The module’s backplane communication ensures I/O signals update in lockstep with robot position (1ms cycle time), critical for tasks like welding seam tracking or precision picking. For plants where robot downtime costs $10k+ per hour, this module isn’t just an I/O expander—it’s a reliability cornerstone that keeps automated lines running smoothly.