Description

Key Technical Specifications

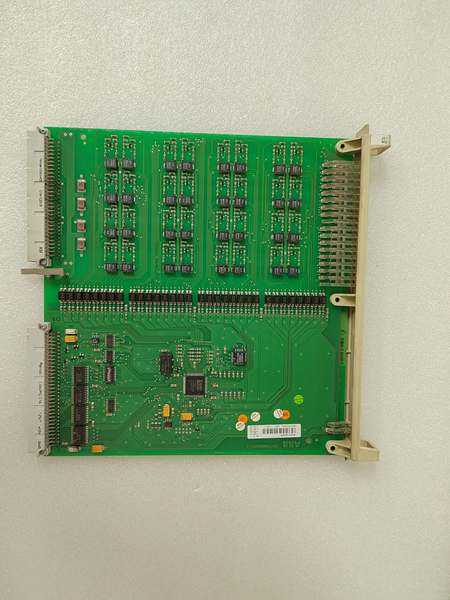

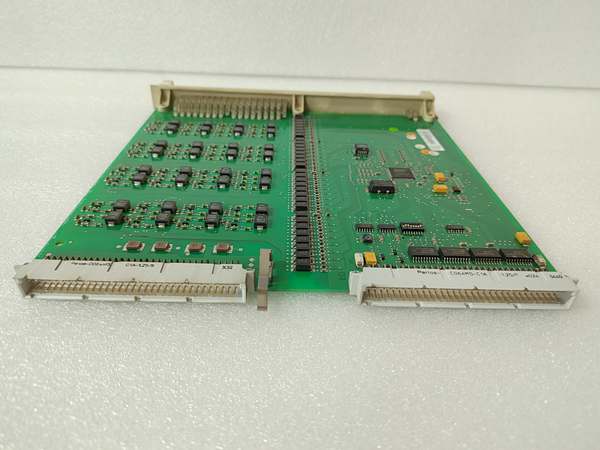

- Model Number: DSDI110A

- Manufacturer: ABB Industrial Automation Division

- Channel Count: 16 fully isolated digital input channels

- Input Type: Configurable NC (Normally Closed) / NO (Normally Open) contacts

- Operating Voltage: 24VDC ±10% (19.2-26.4VDC)

- Input Current: 4mA per channel (sinking/sourcing configurable)

- Isolation Rating: 500V AC (channel-to-channel); 1kV AC (input circuits to backplane)

- Operating Temperature: -25°C to +65°C (-13°F to +149°F)

- Response Time: ≤1ms (standard), ≤0.1ms (fast mode configurable)

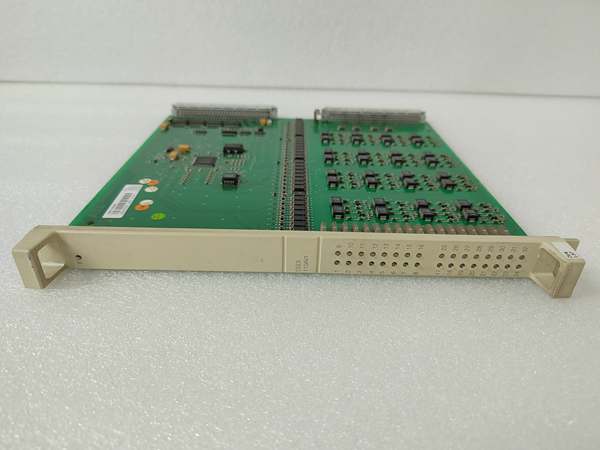

- Mounting Type: Rack-mount (S800 I/O rack, 2U height), plug-in module

- Certifications: CE, UL 508, ATEX Zone 2, RoHS 2.0, IEC 61131-2

- Compatibility: ABB AC800M DCS, S800 I/O racks (IM801/IM810), Control Builder M software, third-party digital sensors/switches

- Diagnostic Capability: Built-in open/short circuit detection, channel status feedback to AC800M CPU, LED indicators per channel

ABB DSDI110A

Field Application & Problem Solved

In industrial process control—refinery pump status monitoring, power plant valve position feedback, chemical reactor safety interlocks—reliable digital input modules are critical for accurate process visibility. The biggest field challenge is generic DI modules failing to integrate with ABB AC800M DCS, suffering from electrical noise interference, or producing false signals in harsh environments. A Texas refinery lost $95k in a 2.5-hour outage when a generic module gave false “pump off” signals, triggering an unnecessary shutdown of a crude oil transfer line. Legacy modules also lack isolation, causing cross-channel interference: a Pennsylvania chemical plant spent $15k annually replacing off-brand units that mixed signals between safety interlocks and non-critical sensors.

You’ll find this module in S800 I/O racks across: refinery distillation unit pump status panels, coal plant boiler feedwater valve position monitoring, and pharmaceutical batch reactor safety door interlocks. Its core value is ABB-native integration + channel-to-channel isolation + noise immunity. Unlike generics, it communicates directly with the AC800M backplane without signal translation, eliminating latency. For an Alaskan natural gas plant, the module’s -25°C operating range and 1kV AC isolation withstood sub-zero temperatures and electrical noise from compressors—something generic modules couldn’t do, reducing false trips by 90%.

Installation & Maintenance Pitfalls (Expert Tips)

- Wiring Polarity: Match Sinking/Sourcing to Sensor: Rookies mix up sinking (NPN) and sourcing (PNP) configurations, causing no signal or module damage. A Michigan paper mill’s limit switches showed “off” when active until the DSDI110A’s input type was configured to match the sensors. Use a multimeter to verify sensor output type and set the module via Control Builder M—never assume default settings work.

- Shielded Cable is Mandatory for Noise Immunity: Unshielded wiring picks up interference from VFDs and motors, leading to false signals. A Florida food processing plant’s safety interlocks tripped falsely until shielded cable was installed. Ground the shield at the DCS end only—daisy-chaining grounds creates noise loops that corrupt digital signals.

- Terminal Torque: Tighten to 1.0Nm: Loose terminals cause intermittent open/short circuit alerts. A Louisiana refinery’s pump status signals fluctuated until terminals were torqued to ABB’s specified 1.0Nm. Use a precision torque screwdriver—over-tightening strips terminal blocks; under-tightening causes arcing and signal loss.

- Overloading Channels: Don’t Daisy-Chain Sensors: Rookies wire multiple sensors to a single channel to save slots, exceeding input current limits. An Ohio steel mill’s DSDI110A failed after 3 months when four limit switches were daisy-chained. Each channel is rated for one sensor—use additional modules if more inputs are needed.

- Ignoring Diagnostic LED Indicators: Rookies overlook per-channel LEDs, missing early warnings of wiring faults. A North Carolina power plant’s valve position sensor was disconnected for 2 days until a technician noticed the DSDI110A’s “open circuit” LED. Use the LEDs to quickly troubleshoot—green = active, red = fault, off = no signal.

ABB DSDI110A

Technical Deep Dive & Overview

The ABB DSDI110A is a dedicated digital input module engineered to convert discrete sensor signals into digital data for ABB’s AC800M DCS. At its core, each of the 16 channels features independent isolation (500V AC) to block cross-channel interference and electrical noise from industrial equipment—critical for refineries and power plants with high electromagnetic interference (EMI). The module’s configurable input type (sinking/sourcing) and NC/NO logic accommodate virtually any digital sensor or switch, eliminating the need for external signal converters.

Unlike generic modules, the DSDI110A communicates directly with the AC800M CPU via the S800 I/O rack’s backplane, ensuring low response times (≤1ms) for time-critical applications like safety interlocks. The module’s diagnostic circuitry continuously monitors for open/short circuits, transmitting fault data to the DCS for real-time alerts. This enables predictive maintenance, as technicians can address wiring issues before they cause downtime.

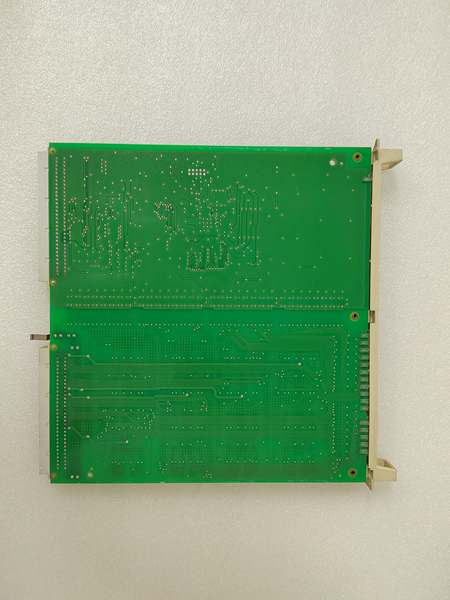

What sets it apart is its rugged design: a conformal-coated PCB resists dust and humidity, and the wide operating temperature range (-25°C to +65°C) makes it suitable for unconditioned control cabinets in harsh environments. For facilities where digital input reliability directly impacts process safety and efficiency, the DSDI110A isn’t just a measurement module—it’s a robust, low-maintenance solution that keeps industrial processes visible and controlled, while integrating seamlessly with ABB’s control ecosystem.