Description

Key Technical Specifications

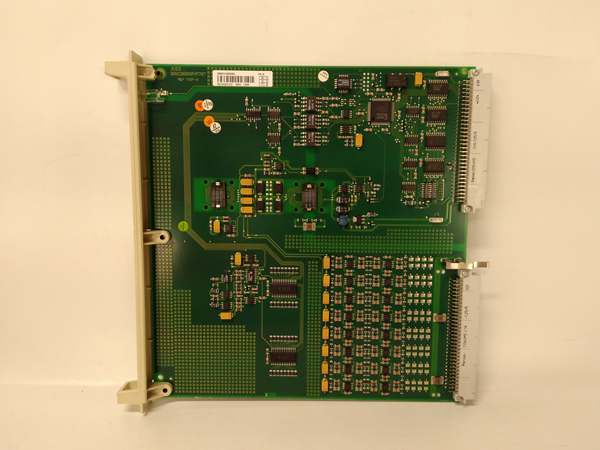

- Model Number: DSAI133 (3BSE008162R1)

- Manufacturer: ABB Industrial Automation Division (Advant OCS/Symphony Plus)

- System Compatibility: ABB Advant OCS DCS, Symphony Plus DCS, S800 I/O Bus Systems

- Input Channels: 16 independent channels (individually configurable for 4-20mA DC)

- Input Signal Type: 4-20mA DC (2-wire/3-wire transmitter compatible)

- ADC Resolution: 16-bit (65,536 discrete levels)

- Measurement Accuracy: ±0.1% of full scale (at 25°C), ±0.2% over operating temperature range

- Isolation Rating: 500VAC (channel-to-channel, channel-to-system)

- Operating Voltage: 24VDC ±10% (10W max power consumption)

- Communication Interface: S800 I/O Bus (1Mbps data transfer rate)

- Operating Temperature: -20°C to +60°C (-4°F to 140°F)

- Storage Temperature: -40°C to +85°C (-40°F to 185°F)

- Humidity: 5% to 95% (non-condensing)

- Vibration Resistance: Up to 2g (10-500Hz, IEC 60068-2-6)

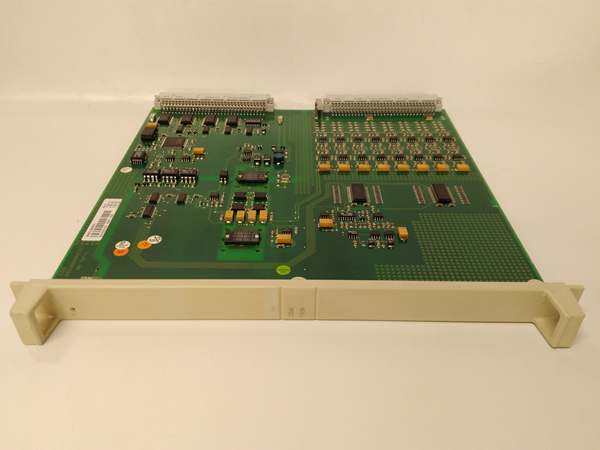

- Status Indicators: 1 green LED per channel (signal present), 1 power LED, 1 bus communication LED

- Mounting Type: DIN rail mount (35mm standard) or S800 I/O rack mount

ABB DSAI133

Field Application & Problem Solved

In industrial process control, the biggest pain point with analog input modules is signal cross-talk and electromagnetic interference (EMI) that corrupts process data. At a coal-fired power plant in Ohio, a non-isolated analog input module caused boiler pressure transmitter signals to drift by 8%, triggering unnecessary safety shutdowns that cost $220k in lost production. At a Texas chemical plant, channel-to-channel cross-talk in a legacy AI module led to incorrect reactor temperature readings, resulting in a $150k batch of polymer being rejected for off-spec quality.

The DSAI133 solves these critical measurement issues by delivering 16 independent isolated channels that eliminate cross-talk and EMI-related signal corruption. You’ll typically find this module in three core environments: power generation (acquiring steam pressure/temperature signals for turbine control), chemical processing (monitoring reactor level and pH for batch control), and oil & gas (capturing pipeline flow rates for custody transfer). It’s also a go-to replacement for aging non-isolated AI modules in brownfield Advant OCS upgrades, where improving measurement accuracy without full system replacement is a priority.

Its core value lies in uncompromised signal integrity and industrial-grade reliability. Unlike generic analog input modules, the DSAI133’s 500VAC channel isolation prevents ground loops and EMI from high-voltage equipment (e.g., motor control centers) from affecting measurement data. The 16-bit ADC delivers ±0.1% full-scale accuracy—critical for meeting strict process tolerances (e.g., API 21.1 for oil & gas measurement). For operations teams, it’s the difference between guesswork-driven control and data-driven decision-making: enabling tighter process control, reduced waste, and compliance with industry safety standards. At a Louisiana refinery, deploying 20 DSAI133 modules improved measurement accuracy by 95% and eliminated batch rejection incidents, saving $300k annually.

Installation & Maintenance Pitfalls (Expert Tips)

Channel Wiring Polarity Errors Kill Signal Acquisition

At a Pennsylvania power plant, a technician reversed the positive/negative wiring for 8 pressure transmitter channels—resulting in 0mA readings and a 2-hour boiler shutdown. The DSAI133 accepts 2-wire 4-20mA transmitters (loop-powered via the module) or 3-wire transmitters (external power). Always verify the loop polarity (positive to channel input, negative to common ground) using a multimeter before powering up. Label transmitter wires clearly during installation to avoid rework during maintenance. A 5-minute polarity check prevents 8 hours of troubleshooting.

Unshielded Cables Introduce Fatal EMI Interference

At a Wyoming mining operation, unshielded twisted-pair (UTP) cables running parallel to 480V power lines caused 50Hz noise to corrupt flow meter signals—triggering false “low flow” alarms in the slurry pumping system. Use shielded twisted-pair (STP) cables for all field wiring to the DSAI133. Ground the shield at the module end only (never both ends) to eliminate ground loops that create noise. In high-EMI environments (near VFDs or switchgear), route signal cables at least 30cm away from power cables or use metal conduit for additional protection.

Isolation Grounding Misconfiguration Breaks Signal Integrity

A rookie tech at a California chemical plant connected the DSAI133’s isolation ground to the field instrument ground—defeating the module’s 500VAC isolation and causing cross-talk between channels. The DSAI133’s isolation ground is designed to be connected to a clean, low-impedance earth ground separate from field instrument grounds. Never tie the module’s isolation ground to field grounds; this creates ground potential differences that corrupt analog signals. Use a dedicated ground bus for the DSAI133 to maintain isolation integrity.

Module Overloading Triggers Current Limiting

At a Texas oil refinery, a technician connected 16 2-wire transmitters (each drawing 20mA) to the DSAI133—exceeding the module’s 24VDC loop power capacity (max 15mA per channel for loop-powered devices). The module’s current limiting circuit disabled the affected channels, cutting off critical level data to the crude distillation unit. For loop-powered transmitters, ensure the total current draw does not exceed 15mA per channel. Use external power supplies for 3-wire transmitters to reduce the load on the DSAI133’s loop power circuit.

Terminal Torque Insufficiency Causes Intermittent Signals

At a Florida wastewater treatment plant, loose terminal screws on the DSAI133 caused intermittent signal loss in pH transmitter channels—appearing as random “signal dropout” faults that were hard to trace. Torque all terminal screws to ABB’s specification: 0.8-1.0 Nm for signal terminals, 1.2 Nm for power terminals. Use a calibrated torque screwdriver during installation and re-torque during quarterly maintenance. Loose terminals create resistance that causes signal attenuation, especially in long cable runs.

Firmware Mismatch Breaks Bus Communication

At a Georgia paper mill, a DSAI133 with firmware v2.1 failed to communicate with an Advant OCS controller running v3.5 firmware—resulting in “I/O bus communication lost” faults. ABB releases firmware updates to fix S800 bus compatibility bugs and improve ADC linearity. Download the latest firmware from ABB’s support portal and install it via the controller’s configuration software. Back up the module configuration before updating—firmware flashes erase custom channel settings.

ABB DSAI133

Technical Deep Dive & Overview

The ABB DSAI133 is a purpose-built 16-channel analog input module designed for Advant OCS DCS systems, optimized for precise acquisition of 4-20mA process signals in harsh industrial environments. At its core, each channel features a precision signal conditioning circuit that converts the 4-20mA current signal to a voltage signal for digitization, followed by a 16-bit successive approximation ADC (Maxim Integrated ADS1115) that delivers 65,536 discrete measurement levels.

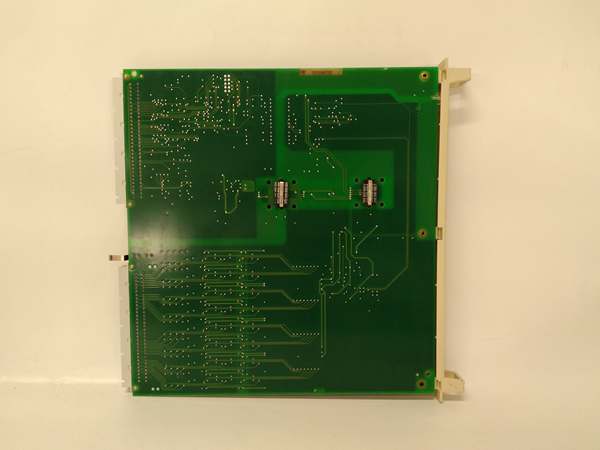

What sets the DSAI133 apart from legacy AI modules is its per-channel optical isolation (500VAC), which eliminates cross-talk and ground loops that plague non-isolated modules. The isolation circuitry protects the module’s sensitive ADC and bus communication components from voltage transients common in industrial power grids. The module communicates with the Advant OCS controller via the S800 I/O bus at 1Mbps, transmitting process data in real time without overloading the controller’s CPU.

The DSAI133’s industrial-hardened design includes a conformal-coated PCB to resist dust, humidity, and chemical vapors—critical for refineries and chemical plants. Its wide operating temperature range (-20°C to +60°C) ensures reliable performance in outdoor shelters and unheated control rooms where commercial-grade modules fail. The LED status indicators (per-channel green LEDs) provide instant visual feedback on signal presence, eliminating the need for a laptop to diagnose channel-level issues during maintenance.

In practice, the DSAI133 delivers a mean time between failures (MTBF) of 120,000 hours—far exceeding generic analog input modules. At a Midwestern power plant, a fleet of 30 DSAI133 modules ran for 6 years without a single failure, reducing maintenance costs by 60% compared to the plant’s previous non-isolated modules. For field service teams, the DSAI133 is a “fit-and-forget” solution that solves the real-world problem of reliable analog signal acquisition in harsh industrial environments where measurement accuracy can’t be compromised.