Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | DSAI130A 3BSE018292R1 |

| Manufacturer | ABB |

| Product category | Digital input module |

| Rated voltage | 24 V DC ±10% |

| Input voltage range | 15 – 30 V DC |

| Number of inputs | 16 (isolated channels) |

| Input type | Dry contact (NO/NC configurable) |

| Input current | 3 mA per channel (max) |

| Isolation rating | 500 V AC (channel-to-channel, channel-to-ground) |

| Response time | ≤1 ms (on), ≤5 ms (off) |

| Communication interface | Profibus DP |

| Operating temperature | 0°C to 60°C |

| Dimensions | 100 mm × 80 mm × 60 mm |

| Mounting type | DIN rail mount (35 mm) |

| Protection rating | IP20 |

| Certifications | IEC 61131-2, CE, UL, RoHS |

| Diagnostic features | Channel-level short-circuit and open-circuit detection |

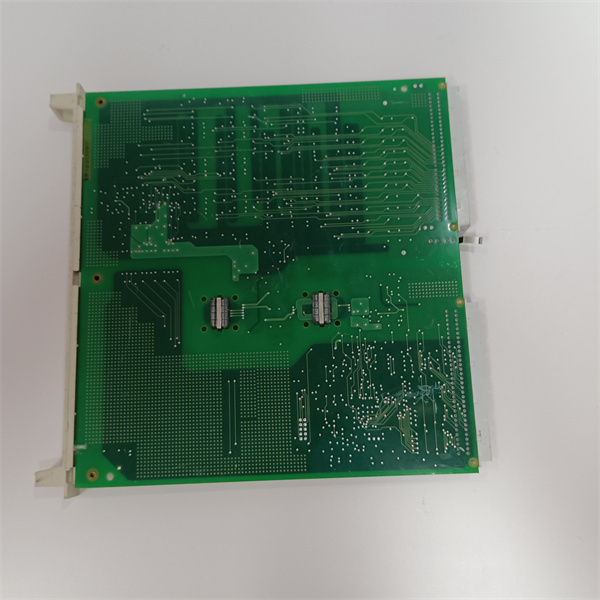

ABB DSAI130A 3BSE018292R1

Product introduction

The DSAI130A 3BSE018292R1 is a compact digital input module from ABB, designed to interface with dry contact sensors and switches in industrial automation systems. As a key component in ABB’s AC 800M controller family, this module converts discrete on/off signals from field devices (such as limit switches, pushbuttons, and relays) into digital data for processing by the control system.

Unlike the DYTP600A, which focuses on high-power terminal connections, the DSAI130A specializes in low-voltage signal acquisition. Its 16 isolated channels ensure interference-free operation in noisy industrial environments, making it ideal for applications like machine control, process monitoring, and building automation. With fast response times and built-in diagnostics, it provides reliable signal detection and simplifies troubleshooting, enhancing system uptime.

Core advantages and technical highlights

High-density isolated inputs

The module’s 16 isolated channels (in a 100 mm × 80 mm footprint) prevent cross-talk between signals, critical in environments with high electromagnetic interference (EMI)—such as near motor drives or welding equipment. Each channel is isolated from others and ground by 500 V AC, ensuring a 3 mA input current doesn’t introduce noise. In an automotive paint shop, this isolation ensures reliable detection of door limit switches despite EMI from nearby robotic arms.

Rapid response times

With a maximum on-response time of 1 ms and off-response time of 5 ms, the DSAI130A outperforms many competing modules in time-critical applications. For example, in a packaging machine, it can detect a jam via a proximity switch and trigger an emergency stop within 1 ms, preventing product damage or equipment wear.

Comprehensive diagnostics

Built-in short-circuit and open-circuit detection at the channel level allows early identification of wiring faults. The module communicates diagnostic data via Profibus DP to the controller, which can alert operators via HMI—reducing troubleshooting time from hours to minutes. In a food processing line, this feature quickly identifies a broken wire to a conveyor belt sensor, minimizing production downtime.

Flexible configuration

Each channel can be configured as normally open (NO) or normally closed (NC) via software, eliminating the need for hardware rewiring when sensor types change. This flexibility is valuable in dynamic environments like assembly lines, where retooling often requires reconfiguring input logic.

Key differences from DYTP600A 61430001-ZY

| Feature | DYTP600A | DSAI130A |

| Primary function | High-power terminal connections | Digital signal acquisition |

| Voltage rating | 1000 V AC/DC | 24 V DC ±10% |

| Current handling | 63 A per terminal | 3 mA per channel |

| I/O type | 12 terminals (6 in, 6 out) | 16 digital inputs |

| Isolation | None (power connections) | 500 V AC (channel-to-channel) |

| Communication | N/A (passive connections) | Profibus DP |

| Environment rating | -30°C to 90°C, ATEX Zone 2 | 0°C to 60°C, general industrial |

ABB DSAI130A 3BSE018292R1

Typical application scenarios

Machine control systems

In a CNC machining center, the DSAI130A monitors 16 limit switches (detecting axis positions) and emergency stop buttons. Its fast response time ensures the machine halts within 1 ms if a tool exceeds travel limits, preventing collisions. Profibus DP communication integrates with the CNC controller, providing real-time status updates to the operator interface.

Process monitoring panels

In a water treatment plant, the module connects to 16 float switches (indicating tank levels) and valve position sensors. Isolated channels prevent ground loops from affecting level readings, while diagnostics alert maintenance when a float switch wire breaks—critical for avoiding overflow or underflow incidents.

Building automation

In a commercial office tower, the DSAI130A interfaces with 16 door contact sensors and motion detectors. Its 24 V DC operation aligns with standard building automation voltages, and software-configurable NO/NC settings simplify integration with existing security systems. Profibus DP enables centralized monitoring of access points via the building management system.

Related model recommendations

ABB DYTP600A 61430001-ZY

Complements the DSAI130A in mixed systems, handling high-power connections for motors/actuators while the DSAI130A manages low-voltage sensor inputs—forming a complete I/O solution.

ABB AC800M controller

The primary control unit that processes data from the DSAI130A, executing logic to control industrial processes based on input signals.

ABB TB857 surge protector

Installed upstream of the DSAI130A to shield against voltage spikes on 24 V DC lines, protecting sensitive input circuitry.

ABB CI854A Profibus adapter

Extends communication distance between the DSAI130A and the controller, useful in large facilities like warehouses or factories.

ABB PM861-ETH processor module

Integrates with the DSAI130A in distributed control systems, enabling Ethernet-based monitoring alongside Profibus DP.

Installation, commissioning and maintenance instructions

Installation: Mount the DSAI130A on a 35 mm DIN rail in a control cabinet, ensuring 20 mm clearance for ventilation. Connect 24 V DC power (protected by a 0.5 A fuse) to the terminal block. Wire dry contacts to input channels 1-16, using 0.5 – 1.5 mm² shielded cable. Ground the cable shield at the module end. Connect the Profibus DP cable to the communication port, using twisted-pair cable with shield.

Commissioning: Configure channel types (NO/NC) via ABB’s Control Builder M software. Verify communication with the controller by checking Profibus DP status indicators. Test each input by activating the connected sensor and confirming signal reception in the controller. Calibrate response times if needed (default settings suffice for most applications).

Maintenance: Inspect quarterly for loose connections and dust (clean with compressed air). Use diagnostic data from the controller to identify faulty channels—replace wiring or sensors before replacing the module. Check power supply voltage annually to ensure it remains within 24 V DC ±10%. Replace the module if channels consistently fail diagnostics or communication is lost.

Service and guarantee commitment

The DSAI130A 3BSE018292R1 is backed by a 5-year warranty, covering manufacturing defects and ensuring compliance with IEC 61131-2 standards. ABB’s technical support provides software configuration guidance and troubleshooting assistance via phone or email, with response within 24 hours.

Extended service includes firmware updates, access to online training modules, and priority technical support. ABB guarantees compatibility with current and future versions of the AC 800M controller software, ensuring long-term system integration. This commitment reflects the module’s role as a reliable foundation for digital input acquisition in industrial automation.