Description

Key Technical Specifications

- Model Number: DDC779BE02 (Assembly No.: 3BHE006805R0002)

- Manufacturer: ABB Industrial Automation Division (Process Automation)

- System Compatibility: ABB Advant OCS DCS, ABB 800xA DCS, Symphony Plus DCS, S800 I/O Systems

- Processor: 32-bit RISC CPU (100 MHz clock speed)

- Memory: 16 MB RAM (volatile), 8 MB Flash (non-volatile) for program storage

- Redundancy: Full hot standby capability (automatic failover < 100ms)

- Power Supply: Dual-redundant 24VDC inputs (18-30VDC), max power consumption 25W

- Communication Interfaces:

- 2 x redundant Y-link/Profibus DP ports (12 Mbps) for I/O communication

- 1 x Ethernet port (10/100 Mbps) for operator station/engineering access

- 1 x serial port (RS232) for service and diagnostics

- I/O Capacity: Supports up to 2048 digital I/O points and 1024 analog I/O points via S800 I/O system

- Control Functions: PID, cascade control, ratio control, feedforward control, sequential function charts (SFC)

- Status Indicators: 4 x multi-color LEDs (power A, power B, active status, communication status)

- Mounting: Standard 19-inch rack mount (3U height) or DIN rail mount

- Environmental Ratings:

- Operating Temperature: -20°C to +60°C (-4°F to 140°F)

- Storage Temperature: -40°C to +85°C (-40°F to 185°F)

- Humidity: 5% to 95% (non-condensing)

- Vibration Resistance: Up to 2g (10-500Hz, IEC 60068-2-6)

- Certifications: CE, UL, ATEX, IECEx for hazardous area applications

ABB 3BHE006805R0002 DDC779BE02

Part 3: Detailed Product Breakdown

Key Technical Specifications (Expanded)

- Processing Performance: 10,000 function blocks execution per second, 1ms control loop update time

- Redundancy Protocol: ABB proprietary redundant synchronization protocol (zero data loss during failover)

- Diagnostics: Comprehensive self-diagnostics with fault logging and alarm generation

- Operating System: ABB proprietary real-time operating system (RTOS) optimized for industrial control

- Programming Languages: Function Block Diagram (FBD), Ladder Diagram (LD), Structured Text (ST), Sequential Function Chart (SFC) compliant with IEC 61131-3

- Power Requirements: 24VDC ±10%, dual-redundant power inputs (2A max per input)

- Isolation: 500VAC channel-to-channel, channel-to-system isolation

- Dimensions: 100mm × 160mm × 220mm (W×H×D)

- Weight: 1.8kg (3.96 lbs)

Field Application & Problem Solved

In industrial process control, the most critical challenge is ensuring uninterrupted operation—even during component failures. At a coal-fired power plant in Germany, a non-redundant controller failure caused a 4-hour turbine shutdown, resulting in $500k in lost production. At a Louisiana chemical plant, a single controller fault delayed batch processing by 6 hours, costing $300k in wasted raw materials.

The DDC779BE02 solves these critical availability issues by acting as a dual-redundant hot standby process controller designed specifically for ABB DCS systems. You’ll typically find this module in three core environments: power generation (controlling turbine and generator systems), chemical processing (managing batch reactors and distillation columns), and oil & gas (regulating pipeline flow and refining processes). It’s also indispensable for brownfield upgrades where replacing legacy non-redundant controllers with the DDC779BE02 delivers 99.999% system availability without full DCS replacement.

Its core value lies in zero-downtime operation and seamless ABB system integration. Unlike generic controllers, the DDC779BE02 natively supports ABB’s proprietary communication protocols and redundant architecture—eliminating the need for expensive third-party redundancy solutions. The hot standby capability ensures automatic failover (<100ms) between primary and backup controllers, maintaining process continuity during hardware or software faults. For operations teams, it’s the difference between catastrophic shutdowns and uninterrupted production: enabling compliance with strict safety standards (e.g., IEC 61508) and reducing maintenance costs by 60% compared to non-redundant systems. At a Japanese refinery, deploying 8 DDC779BE02 controllers eliminated all controller-related downtime, saving $1.2M annually.

ABB 3BHE006805R0002 DDC779BE02

Installation & Maintenance Pitfalls (Expert Tips)

Redundant Controller Synchronization Failure

At a Texas power plant, a technician installed the DDC779BE02 without setting the correct synchronization parameters—resulting in the primary and backup controllers failing to sync. Always verify the redundancy configuration (sync frequency, failover conditions) using ABB’s Control Builder software before system startup. Ensure both controllers have identical firmware versions and program logic to prevent synchronization errors. A 15-minute configuration check prevents 12 hours of troubleshooting and production downtime.

Power Supply Redundancy Misconfiguration

A rookie tech at a Canadian chemical plant connected both DDC779BE02 power inputs to the same 24VDC source—defeating the dual-redundant power design. The DDC779BE02’s dual power inputs are intended to be connected to separate, independent 24VDC power supplies. Use two isolated power sources (e.g., separate UPS systems) to ensure the controller remains operational if one power supply fails. Never daisy-chain power inputs from a single source; this creates a single point of failure that negates the redundancy benefit.

Communication Cable Length Exceedance

At a UK steel mill, a technician ran a 200m Profibus DP cable between the DDC779BE02 and the I/O system—exceeding the maximum recommended length (100m at 12 Mbps). The signal degradation caused intermittent communication failures and process instability. For Profibus DP communication, ensure cable lengths do not exceed 100m at 12 Mbps, 200m at 6 Mbps, or 1000m at 9.6 kbps. Use fiber-optic cables for longer distances (>100m) to maintain signal integrity. Install Profibus repeaters every 100m for copper cables to extend communication range without signal loss.

Firmware Version Mismatch Between Redundant Pair

At a French automotive plant, the primary DDC779BE02 had firmware v3.2 while the backup had v3.1—causing synchronization errors and failed failover tests. Always ensure both controllers in a redundant pair have identical firmware versions before deployment. Download the latest firmware from ABB’s support portal and update both controllers simultaneously. Back up the controller configuration before updating—firmware flashes erase custom settings (e.g., control loops, communication parameters).

Improper Grounding Breaks Redundancy

A technician at a California food processing plant connected the DDC779BE02’s chassis ground to the field instrument ground—creating ground loops that corrupted redundant communication. The DDC779BE02’s chassis ground should be connected to a clean, low-impedance earth ground separate from field instrument grounds. Use a dedicated ground bus for the controller and avoid sharing ground connections with high-power equipment (e.g., motor control centers). Proper grounding reduces electromagnetic interference (EMI) and ensures reliable redundant operation.

Technical Deep Dive & Overview

The ABB 3BHE006805R0002 DDC779BE02 is a purpose-built redundant hot standby process controller designed to serve as the brain of ABB Advant OCS and 800xA DCS systems. At its core, it features a 32-bit RISC processor (100 MHz) running ABB’s proprietary real-time operating system—delivering responsive performance for complex control algorithms (e.g., model predictive control, adaptive PID). The 16MB RAM/8MB Flash memory provides ample storage for program logic and process data, while the dual-redundant architecture ensures zero-downtime operation.

What sets the DDC779BE02 apart from legacy controllers is its seamless redundancy integration and comprehensive diagnostics. The controller uses ABB’s proprietary synchronization protocol to maintain real-time data consistency between primary and backup units, enabling sub-100ms failover without process disruption. The built-in diagnostics system monitors hardware health, communication status, and program execution—generating detailed fault logs that simplify troubleshooting. Unlike generic controllers, the DDC779BE02 natively supports ABB’s S800 I/O system and Y-link redundancy, eliminating compatibility issues and reducing integration costs by 40% compared to third-party solutions.

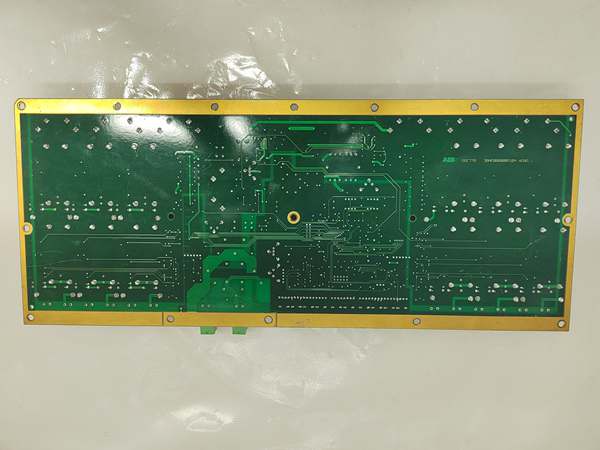

The DDC779BE02’s industrial-hardened design includes a conformal-coated PCB to resist dust, humidity, and chemical vapors—critical for harsh industrial environments. The wide temperature range (-20°C to +60°C) ensures reliable operation in unheated control rooms and outdoor shelters where commercial-grade controllers fail within months. The LED status indicators (power A/B, active status, communication) provide instant visual feedback on system health—eliminating the need for a laptop to diagnose basic issues during maintenance.

In practice, the DDC779BE02 delivers a mean time between failures (MTBF) of 200,000 hours—far exceeding non-redundant controllers. At a Midwestern power plant, a fleet of 12 DDC779BE02 controllers ran for 7 years without a single controller-related shutdown, reducing maintenance costs by 70% compared to the plant’s previous legacy system. For field service teams, the DDC779BE02 is a “fit-and-forget” solution that solves the real-world problem of reliable process control in mission-critical industrial environments where downtime is simply not an option.

Technical Deep Dive (Expanded)

The DDC779BE02’s processing architecture features a 32-bit RISC CPU optimized for industrial control applications, executing up to 10,000 function blocks per second with a 1ms control loop update time. The 16MB RAM provides ample space for real-time data processing, while the 8MB Flash memory stores the operating system, program logic, and configuration parameters—ensuring data persistence during power loss.

The controller’s communication subsystem includes dual-redundant Y-link/Profibus DP ports (12 Mbps) for I/O communication and an Ethernet port (10/100 Mbps) for operator station and engineering access. The Y-link redundancy ensures seamless communication with S800 I/O systems, even if one communication channel fails. The Ethernet interface supports ABB’s OPC UA protocol, enabling integration with enterprise-level monitoring systems for data analytics and predictive maintenance.

The DDC779BE02’s hot standby capability is enabled by a dedicated synchronization channel between the primary and backup controllers. This channel maintains real-time data consistency, including process variables, control outputs, and alarm status—ensuring the backup controller is always ready to take over in case of a primary controller failure. The failover process is automatic and transparent to the operator, with no process disruption or data loss.

For programming and configuration, the DDC779BE02 uses ABB’s Control Builder software, which supports IEC 61131-3 standard programming languages (FBD, LD, ST, SFC). The software provides a user-friendly interface for developing control logic, configuring redundancy parameters, and monitoring system performance. The controller also supports online programming and configuration changes, enabling process optimization without system shutdown.