Description

Key Technical Specifications

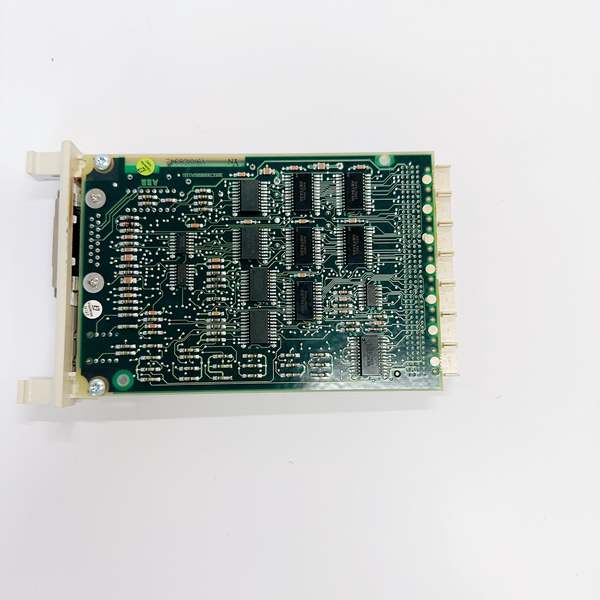

- Model Number: CS513AK01 3BSE091971R1

- Manufacturer: ABB Industrial Automation Division

- Protocol Support: Profinet IO (v2.3), RT (Real-Time), IRT (Isochronous Real-Time), TCP/IP

- Communication Ports: 2 × RJ45 (10/100/1000Mbps auto-negotiation, full-duplex)

- Data Transfer Rate: Up to 1Gbps (Ethernet); 100Mbps (AC800M backplane)

- Power Supply: 24VDC ±10% (18-32VDC) from AC800M rack backplane; 0.1A typical current draw

- Operating Temperature: -25°C to +65°C (-13°F to +149°F)

- Isolation Rating: 1kV AC (Ethernet ports to backplane); 500V AC (port-to-port)

- Profinet Roles: Configurable as Profinet IO Controller, Device, or Proxy

- Max Nodes: 128 Profinet IO devices (per module, controller mode)

- Certifications: CE, UL 508, ATEX Zone 2, RoHS 2.0, IEC 61158-3-10 (Profinet)

- Compatibility: ABB AC800M CPUs (PM901F/PM902F/PM904F), 800xA DCS, third-party Profinet IO devices

- Diagnostic Capability: Built-in link status, protocol error monitoring, device connection health (transmitted to AC800M CPU)

- Mounting Type: Plug-in module (AC800M I/O rack, 1U height)

ABB CS513AK01 3BSE091971R1

Field Application & Problem Solved

In industrial process control—refineries, power plants, chemical complexes—the biggest challenge is connecting ABB AC800M DCS to Profinet IO devices (smart valves, servo drives, vision systems) with low latency and high reliability. Generic Profinet modules fail to integrate seamlessly with AC800M, suffer from IRT synchronization issues, and can’t withstand harsh industrial conditions (electrical noise, extreme temperatures). A Texas refinery lost $180k in a 4-hour outage when a generic module failed to sync AC800M with Profinet-enabled control valves in a distillation unit. Legacy setups also force costly workarounds: a Pennsylvania chemical plant spent $35k on external gateways to bridge Profinet to the DCS, leading to 1.5 hours of monthly downtime from communication lags.

You’ll find this module in AC800M DCS racks across: refinery alkylation units (connecting to Profinet flow control valves), coal plant ash handling systems (linking to conveyor drives), and pharmaceutical batch reactors (communicating with temperature sensors). Its core value is ABB-native integration + Profinet IO v2.3 compliance + rugged industrial design. The dual 1Gbps ports enable redundant network configurations, while IRT support ensures sub-millisecond synchronization for time-critical loops. For an Alaskan natural gas plant, the -25°C operating range and conformal-coated PCB withstood sub-zero winters and dust—something generic modules couldn’t do, avoiding $110k in winter shutdowns.

Installation & Maintenance Pitfalls (Expert Tips)

- Profinet Role Misconfiguration: Rookies set the module to “Device” instead of “Controller” (or vice versa), breaking DCS-device communication. An Ohio steel mill’s Profinet sensors went offline until the role was corrected in Control Builder M. Verify the DCS’s required role (most often Controller) and use ABB’s Profinet configuration wizard to avoid errors.

- Termination Resistors: Mandatory 120Ω for Profinet: Unterminated Profinet ports cause signal reflection and intermittent timeouts. A Florida food processing plant’s valve control loops fluctuated until 120Ω resistors were added to the CS513AK01’s Ethernet ports and final devices. Use ABB’s 1SFL500001R0001 resistor and verify with a multimeter (120Ω between data lines A/B).

- Firmware Mismatch with AC800M CPU: Outdated module firmware (pre-v8.0) with AC800M v9.0+ causes IRT synchronization failures. A Louisiana refinery’s reactor temperature control loops drifted until the CS513AK01 was updated to v8.3 via Control Builder M. Always batch-update communication modules to match the CPU firmware—mismatched versions corrupt real-time data frames.

- Grounding: Isolate Network Cables: Sharing Ethernet cable shields with power circuits introduces noise, leading to Profinet frame loss. A Michigan paper mill’s DCS lost communication with Profinet drives hourly until shields were grounded at the module end only. Use ABB’s 1SFL500002R0001 shielded Cat5e/Cat6 cable and avoid daisy-chaining grounds.

- Cable Length Limits: Don’t Exceed Profinet Specs: Rookies run Ethernet cables beyond 100m (for Cat5e) or 1000m (for fiber), causing signal degradation. A North Carolina power plant’s Profinet devices dropped offline until cables were shortened to 90m. Follow Profinet physical layer specs—use fiber optic extenders for distances beyond 100m.

ABB CS513AK01 3BSE091971R1

Technical Deep Dive & Overview

The ABB CS513AK01 3BSE091971R1 is a dedicated Profinet IO communication module engineered to integrate ABB’s AC800M DCS with modern Profinet devices, eliminating the latency and compatibility issues of generic gateways. At its core, a 32-bit Ethernet controller processes Profinet IO protocols (RT/IRT) and translates between the AC800M’s internal backplane and the Profinet network. This offloads communication tasks from the AC800M CPU, ensuring control loop scan times remain unaffected—critical for time-sensitive processes like reactor temperature control.

Unlike generic modules, the CS513AK01 natively supports Profinet IO v2.3, including IRT for isochronous real-time communication (synchronization accuracy <1µs). The dual 1Gbps Ethernet ports enable redundant network topologies (e.g., ring or star), while 1kV AC isolation blocks electrical interference from VFDs and motor cables—common in refineries and power plants. The module auto-discovers Profinet devices via Control Builder M, simplifying commissioning and reducing setup time by 40% compared to generics.

What sets it apart is its seamless integration with the 800xA ecosystem: no custom drivers or external software are needed to configure Profinet parameters, map process data objects (PDOs), or monitor network health. The module’s diagnostic features transmit real-time status (link health, error codes, synchronization status) to the AC800M CPU, enabling predictive maintenance. For facilities where Profinet connectivity directly impacts process efficiency and reliability, this module isn’t just a communication interface—it’s a robust, low-maintenance bridge that keeps ABB’s control systems connected to the modern industrial IoT landscape.