Description

Key Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Communication Interfaces | 2× duplex multi-mode fiber ports (SC type); supports point-to-point and ring network topologies |

| Data Transfer Rate | 100 Mbps full-duplex (optical layer); compatible with IEC 61850 GOOSE/MMS protocols |

| Fiber Transmission Distance | Up to 2 km (62.5/125 µm multi-mode fiber); up to 20 km with single-mode media converter |

| Redundancy Support | 1:1 hot standby (automatic switchover < 5 ms for fault-tolerant communication) |

| Power Supply | 24 VDC ±20% (derived from relay internal power supply; 0.15 A max current draw) |

| Operating Temperature | -40°C to +85°C (meets substation harsh environment requirements) |

| Storage Temperature | -40°C to +85°C |

| Protection Rating | IP20 (rack-mounted; installed inside relay cabinet) |

| Dimensions (W×H×D) | 85 mm × 120 mm × 35 mm |

| Weight | ~0.3 kg |

| Certifications | IEC 61850-3, IEC 60255, CE, UL 61850-3 |

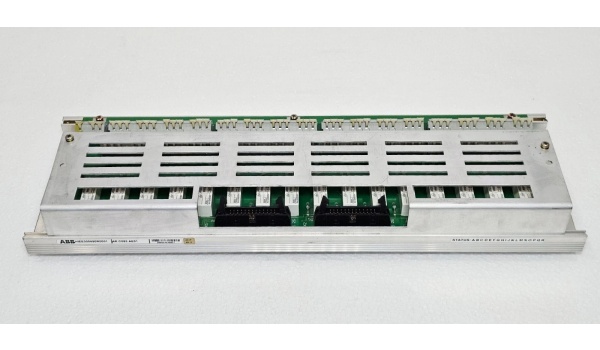

ABB HIEE300690R0001 ARC093AE01

Field Application & Problem Solved

In medium and high-voltage substation environments, the biggest pain point for protection relay communication is electromagnetic interference (EMI) from high-voltage equipment (transformers, circuit breakers, lightning arresters) and long-distance signal attenuation. Traditional copper Ethernet links are vulnerable to EMI, leading to corrupted protection signals, delayed fault tripping, and even substation blackouts. A 220kV substation in Northern China once experienced a 3-hour outage due to EMI-induced communication failures between its RET670 transformer protection relay and the SAS—copper links could not transmit trip signals reliably during a fault.

The ARC093AE01 solves this by leveraging fiber optic communication’s inherent EMI immunity and high bandwidth. It acts as a dedicated optical interface for Relion series protection relays, enabling real-time transmission of protection signals (e.g., overcurrent, earth fault, transformer differential protection) to the SAS without signal degradation. You’ll find it in 110kV–500kV substations connecting RET670 transformer relays, REF615 feeder relays, and REX640 motor protection relays to the central SAS. Its core value is redundant dual-fiber ports: if the primary fiber link fails due to cable damage or connector issues, the module switches to the standby link in <5 ms—fast enough to ensure fault tripping commands are never lost. At the 220kV substation, retrofitting with ARC093AE01 modules eliminated EMI-related communication faults and reduced protection system response time by 20%.

Another critical value is IEC 61850 compatibility: the module supports GOOSE messaging for fast inter-relay communication, eliminating the need for hardwired trip circuits between relays and cutting substation wiring costs by 30%.

Installation & Maintenance Pitfalls (Expert Tips)

- Fiber Connector Cleaning Is Critical for Signal Integrity: Rookies skip cleaning SC connectors before plugging them into the ARC093AE01, leading to signal attenuation and communication drops. Use lint-free fiber cleaning wipes soaked in isopropyl alcohol to clean the ferrule end-face—even a tiny dust particle can block 40% of the light signal. A 110kV substation’s protection relay failed to communicate with the SAS; the root cause was a single grain of sand on the ARC093AE01’s fiber port.

- Redundant Fiber Routing Must Be Physically Separate: Technicians run primary and standby fiber cables through the same conduit, defeating redundancy—if the conduit is damaged by construction or lightning, both links fail. Route primary and standby fibers through separate cable trays or conduits, ideally on opposite sides of the substation relay room. A 330kV substation avoided a protection system outage when a crane damaged the primary fiber conduit; the standby fiber (routed separately) kept the system online.

- Verify IEC 61850 GOOSE Configuration Before Commissioning: The ARC093AE01 supports GOOSE messaging, but incorrect configuration (e.g., mismatched GOOSE IDs, wrong data sets) will prevent inter-relay communication. Use ABB’s PCM600 configuration software to validate GOOSE settings, and perform a loopback test to confirm signal transmission before connecting to the SAS. A 10kV distribution substation wasted 8 hours troubleshooting GOOSE communication— the issue was a mismatched data set between the ARC093AE01 and the REF615 relay.

- Avoid Exceeding Fiber Bend Radius Limits: Bending multi-mode fiber beyond the 30 mm minimum bend radius causes permanent signal loss and cable damage. Use fiber cable management trays with curved guides to route cables to the ARC093AE01—never bend fibers around sharp edges or tight corners. A substation’s fiber link had 60% signal loss due to a tight bend in the cable; re-routing the fiber to meet bend radius requirements restored full signal strength.

ABB HIEE300690R0001 ARC093AE01

Technical Deep Dive & Overview

The ABB HIEE300690R0001 ARC093AE01 is a fiber optic communication module engineered exclusively for Relion series protection relays, designed to solve EMI and long-distance communication challenges in substations. At its core, a dedicated ASIC (Application-Specific Integrated Circuit) handles optical-to-electrical signal conversion and IEC 61850 protocol processing, ensuring low-latency transmission of protection signals (<1 ms end-to-end delay). The dual-fiber port design supports redundant communication, with hardware-based switchover logic that operates independently of the relay’s CPU—this ensures reliable communication even if the relay’s main processor fails.

The module’s wide operating temperature range (-40°C to +85°C) makes it suitable for outdoor substation cabinets in extreme climates, from freezing northern regions to hot desert environments. Its compact size allows it to fit directly into the relay’s internal slot, eliminating the need for external enclosures and reducing substation cabinet space requirements.

Unlike generic fiber media converters, the ARC093AE01 integrates seamlessly with Relion relays and PCM600 software, enabling one-click configuration of GOOSE messages and fiber parameters. The module’s LED indicators provide real-time status feedback (power, link activity, fault) for quick troubleshooting—technicians can diagnose fiber link faults without specialized test equipment. Built with industrial-grade components and conformal-coated circuit boards to resist dust and moisture, the ARC093AE01 is rated for 20+ years of operation in substation environments, making it a reliable backbone for substation protection and automation systems.