Description

Key Technical Specifications

- Model Number: 5SHX2645L0002

- Manufacturer: ABB

- Protocol Support: N/A (Power semiconductor module, no communication protocols; integrates with industrial control systems via hardwired power connections)

- Rated Voltage: 2600V

- Rated Current: 4500A

- Switching Frequency: 20 kHz

- Junction Temperature: 175°C

- Operating Temperature: -40℃~+150℃

- Isolation: High-voltage isolation compliant with industrial power semiconductor standards

- Package Type: Rugged industrial housing (compatible with 91mm frame size)

- Cooling Method: Natural cooling (adaptable to forced air or liquid cooling for high-load scenarios)

- Protection Features: Over-current protection, over-temperature protection

- Frame Size: 91 mm

- Weight: 5 kg

ABB 5SHX2645L0002

Field Application & Problem Solved

In the field, high-power industrial systems—from large motor drives in paper mills to inverters in wind turbines—face two critical pain points: inefficient power conversion that wastes energy and unreliable performance under extreme voltage/current spikes. This module solves both by combining high power density with low conduction losses, a gap that older thyristor modules couldn’t bridge due to their slow switching and high energy waste.

You will typically find this module in heavy-industry and renewable energy settings. In steel mills, it powers the large AC drives that control rolling mill motors, where consistent power delivery prevents material defects. In wind farms, it integrates into grid-tie inverters, converting variable-frequency AC from turbines into stable power for the electrical grid. It’s also used in electric traction systems for locomotives and high-power welding equipment, where it handles the rapid power fluctuations of dynamic loads.

Its core value lies in balancing performance and durability. For plant operators, this translates to lower operational costs—its low on-voltage drop cuts energy waste, while its rugged design reduces unplanned downtime. In critical applications like refinery pump drives, where a component failure could halt production, its built-in over-current and over-temperature protections add a safety layer that prevents cascading system damage. This reliability is invaluable in environments where maintenance windows are rare and costly.

Installation & Maintenance Pitfalls (Expert Tips)

- Ignoring Frame Size Alignment: A common rookie mistake is mismatching the module’s 91mm frame size with incompatible mounting brackets. Misalignment creates uneven pressure on the module’s terminals, leading to poor contact resistance and overheating. Always use ABB-specified mounting hardware and verify bracket dimensions before installation—this prevents premature failure in high-vibration industrial settings like power plants.

- Inadequate Cooling System Calibration: While the module supports natural cooling, many applications push it beyond base-load conditions. Technicians often skip calibrating supplementary cooling (forced air or liquid) to match load demands. This leads to junction temperature spikes above 175°C, which degrades the IGBT chips over time. Use thermal imaging during commissioning to confirm cooling systems keep temperatures within the safe range, especially for 24/7 operations.

- Neglecting Terminal Torque Specifications: Over-tightening or under-tightening power terminals is a frequent error. Over-tightening strips the terminals, while loose connections cause arcing and terminal melting—both catastrophic for high-current applications. Use a torque wrench set to ABB’s recommended values (typically 15-20 N·m for this module) and recheck torque after the first week of operation, as thermal cycling can loosen connections.

- Skipping Compatibility Checks with Drive Systems: Technicians sometimes assume the module works with any high-power drive, but it must match the drive’s voltage and current ratings. Pairing it with a drive rated for lower voltage can cause voltage breakdown during switching. Always cross-reference the module’s 2600V rating with the drive’s input/output parameters; never substitute it for lower-voltage modules even in emergency situations.

ABB 5SHX2645L0002

Technical Deep Dive & Overview

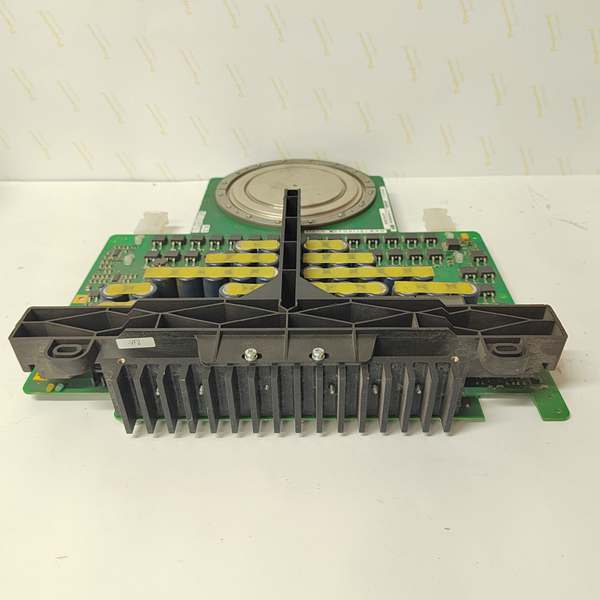

The ABB 5SHX2645L0002 is an integrated high-power IGBT module that combines multiple IGBT chips and free-wheeling diodes in a single rugged housing. Unlike discrete power components, it consolidates critical power switching functions into a compact unit, simplifying integration into high-power systems. The module operates by using the IGBT’s insulated gate to control the flow of large currents between the collector and emitter terminals—its fast 20 kHz switching speed allows it to convert power efficiently between AC and DC, a necessity for variable-speed motor drives and renewable energy inverters.

It communicates with system controls indirectly through its performance parameters rather than a digital backplane. When integrated into a drive or inverter, the module responds to gate signals from the system’s control board, adjusting switching timing to regulate voltage and current output. Its low on-voltage drop minimizes energy loss during conduction, a key advantage over older power modules that waste significant energy as heat. The rugged housing and thermal design also ensure that heat generated during switching is dissipated evenly, preventing hotspots that would shorten component life.

The module’s design prioritizes scalability and reliability. Its standard 91mm frame size allows for easy replacement in existing ABB 5SHX series installations, and its compatibility with multiple cooling methods means it can be adapted to different environmental constraints—from dusty refineries using forced air cooling to compact wind turbine nacelles using liquid cooling. Overall, it acts as the backbone of high-power conversion systems, translating control signals into stable, efficient power for the most demanding industrial and renewable energy applications.