Description

Key Technical Specifications

-

Model Number: 5716-0001-GF DSDP150

-

Manufacturer: ABB Industrial Automation

-

Channel Configuration: 8 digital input channels, fully isolated (channel-to-channel)

-

Input Type: Dry contact/voltage input, 24VDC (sinking/sourcing configurable)

-

Input Voltage Range: 19.2VDC to 30VDC, threshold voltage: 11VDC (min on), 5VDC (max off)

-

Communication Protocol: MasterBus 300, baud rate up to 1Mbps

-

Hazardous Area Rating: ATEX Zone 1/21, IECEx Ex d IIC T6 Ga

-

Operating Temperature: -40°C to +70°C (-40°F to +158°F)

-

Isolation Rating: 2.5kV AC (channel to bus), 500V AC (channel to channel)

-

Physical Design: Rack-mount, 100mm×150mm×80mm (W×H×D), aluminum housing

-

Special Features: Hot-swappable, built-in fault diagnostics, surge protection

-

Certifications: ATEX, IECEx, UL 913, CSA C22.2 No. 213

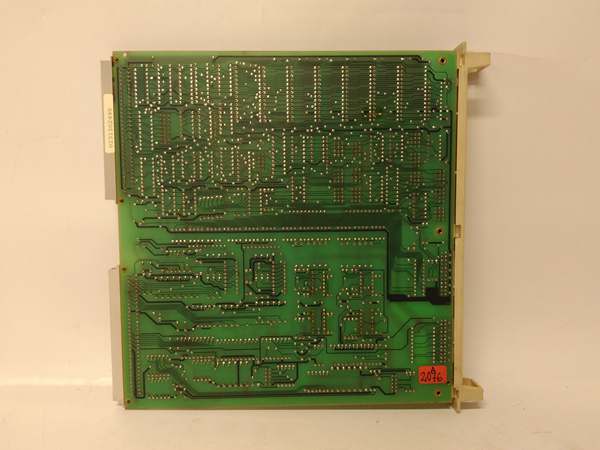

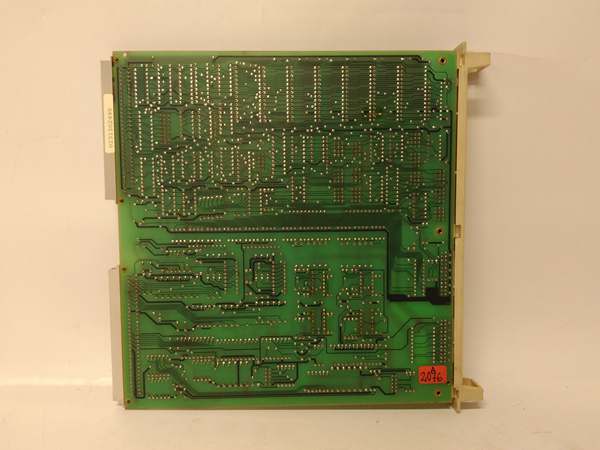

ABB 5716-0001-GF DSDP150

Field Application & Problem Solved

In hazardous areas like oil refinery process units or chemical plant reactor bays, the biggest headache is reliable digital input monitoring. Legacy I/O modules either lack explosion-proof ratings (forcing costly remote cabinets) or have poor isolation, leading to false signals from electromagnetic interference (EMI). I once saw a Texas refinery’s emergency shutdown system (ESD) trip twice in a week because a non-certified DI module picked up noise from nearby pump motors—costing $1.2 million in downtime. Another plant in Louisiana struggled with corroded terminal blocks on old modules, causing intermittent “valve closed” signals that violated safety protocols.

You’ll find the DSDP150 mounted in explosion-proof enclosures right at the process skid—monitoring everything from valve limit switches to pump run/stop statuses in ATEX Zone 1 areas. It’s the “eyes” of the Advant OCS DCS, converting physical contact signals into digital data and sending it back to the controller via MasterBus 300. Its core value is hazardous area compliance plus rugged reliability: the Ex d IIC rating lets it live where gases like methane or ethylene are present, while 2.5kV isolation blocks EMI from high-voltage equipment. At a Gulf Coast chemical plant, we replaced legacy remote I/O with these modules, cutting cable costs by 60% and eliminating noise-related false alarms.

Hot-swappability is another lifesaver in 24/7 processes. A refinery in Oklahoma had a DSDP150 fail due to a power surge—we pulled the faulty module and plugged in a spare in 2 minutes, no shutdown needed. The built-in diagnostics are key too: the module flags open circuits or overvoltage conditions, so we don’t waste hours tracing “no signal” faults. Last year, we used the diagnostic LED to pinpoint a corroded limit switch wire on a reactor valve—fixing it in 15 minutes instead of the usual 2 hours.

Installation & Maintenance Pitfalls (Expert Tips)

Terminal Block Torque Matters—Don’t Over-Tighten

Rookies crank down terminal screws with a standard screwdriver, stripping the threads or crushing the wire insulation. The DSDP150’s terminals require exactly 0.8N·m of torque—use a torque screwdriver (ABB part 3HNA010777-001) to get it right. A plant in Texas had 3 channels fail because of over-tightened terminals; the wires frayed inside, causing intermittent connections. We re-terminated the wires with proper torque, and the module ran flawlessly. Also, use tinned copper wire—stranded wire without tinning will loosen over time from vibration.

Bus Termination Resistor Is Mandatory

MasterBus 300 networks fail if the end module doesn’t have a 120Ω termination resistor. The DSDP150 has a built-in switch (labeled “TERM”)—flip it to “ON” only for the last module in the bus chain. A Louisiana refinery forgot this, and the entire I/O network dropped out every time a pump started. We turned on the resistor switch on the end module, and the network stabilized. Also, keep bus cable runs under 1000 meters—longer runs cause signal degradation, even with the resistor.

Surge Protection Isn’t Optional in Hazardous Areas

The DSDP150 has basic surge protection, but in areas with lightning or frequent power spikes, add ABB’s OVR 20 series surge arresters (part 10154511) to the power and signal lines. A Florida plant skipped this, and a lightning strike fried 4 modules—$8,000 in replacement costs. Also, use shielded twisted-pair (STP) cable for the MasterBus, grounding the shield only at the controller end. Double grounding creates loops that introduce noise, leading to false “channel fault” alarms.

Configuration DIP Switches—Double-Check Before Power-Up

The module’s DIP switches set the address (0-31) and input type (sinking/sourcing). A common mistake is swapping address switches—e.g., setting address 5 instead of 6—causing the DCS to “lose” the module. Use the ABB Advant Station software to verify the address matches the DIP switch setting. A Pennsylvania plant had 2 modules with swapped addresses; the DCS showed one as “fault” and the other as “comm lost.” Fixing the DIP switches took 2 minutes, saving hours of troubleshooting.

ABB 5716-0001-GF DSDP150

Technical Deep Dive & Overview

The 5716-0001-GF DSDP150 is a distributed digital input module for ABB’s Advant OCS control system, built to handle the harsh conditions of hazardous industrial environments. Each of its 8 channels has an independent opto-isolator, so a fault on one channel (like a shorted wire) doesn’t affect the others—critical for safety systems. The module’s aluminum housing and flameproof design contain any internal arcs, making it safe for Zone 1 areas where flammable gases are present.

It communicates with the Advant OCS controller via MasterBus 300, a rugged industrial bus that supports up to 32 modules per segment. The module converts 24VDC input signals (from limit switches, pressure switches, etc.) into digital data, which is transmitted to the controller at 1ms intervals. The built-in diagnostics monitor each channel for open circuits, overvoltage, and short circuits, with LED indicators on the front panel for quick fault identification.

The hot-swappable design uses spring-loaded connectors that maintain bus communication while the module is being replaced—no need to shut down the entire I/O segment. Its -40°C to +70°C operating range handles everything from arctic oil fields to desert refineries. With a MTBF of over 300,000 hours and ATEX/IECEx certifications, it’s the go-to DI module for hazardous area applications where reliability and safety can’t be compromised.