Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 500BIM01 1MRB160024R0002 |

| Manufacturer | ABB |

| Product category | Industrial biological monitoring system |

| Detection range | 0-5000 CFU/mL (viable bacteria), 0-1000 ppm (total organic carbon) |

| Measurement accuracy | ±2% of full scale |

| Response time | ≤20 seconds (bacteria), ≤5 seconds (TOC) |

| Communication interfaces | PROFINET, Modbus TCP/IP, OPC UA, 4-20mA |

| Operating voltage | 24V DC ±15% / 110-230V AC |

| Power consumption | Max 15W |

| Operating temperature | 0°C to 55°C |

| Protection rating | IP67 (sensor), IP20 (controller) |

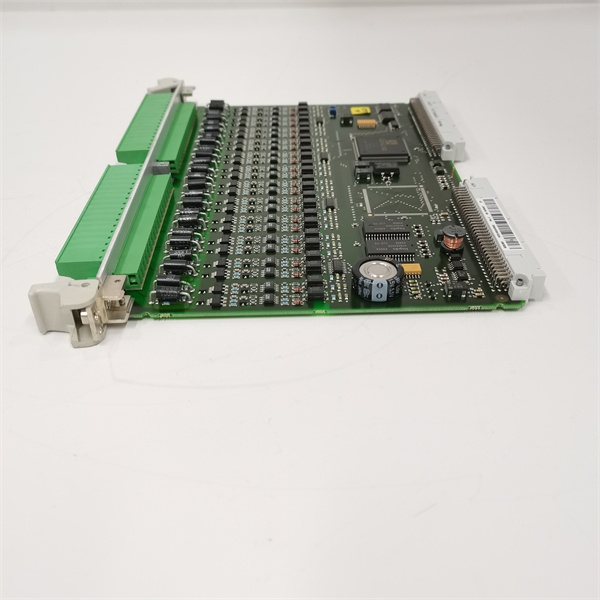

| Mounting type | In-line / bypass flow (sensor), DIN rail (controller) |

| Dimensions | Sensor: 65mm × 180mm; Controller: 120mm × 140mm × 80mm |

| Certifications | ISO 13485, IEC 61010-1, CE, FDA Class II, 3-A Sanitary, cGMP

Product introduction |

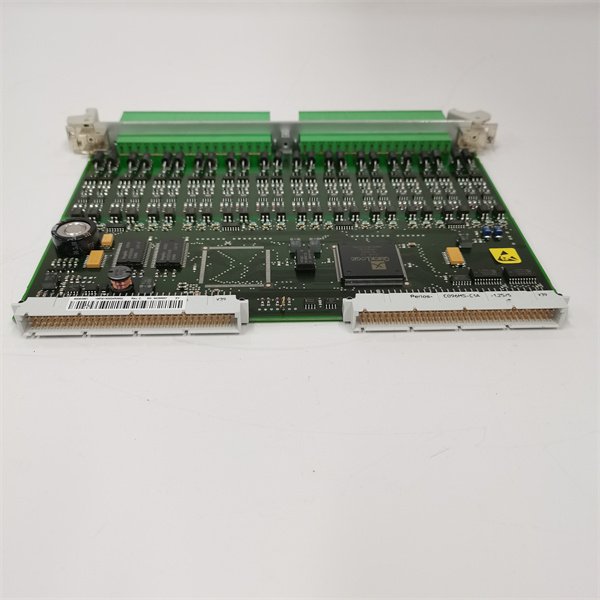

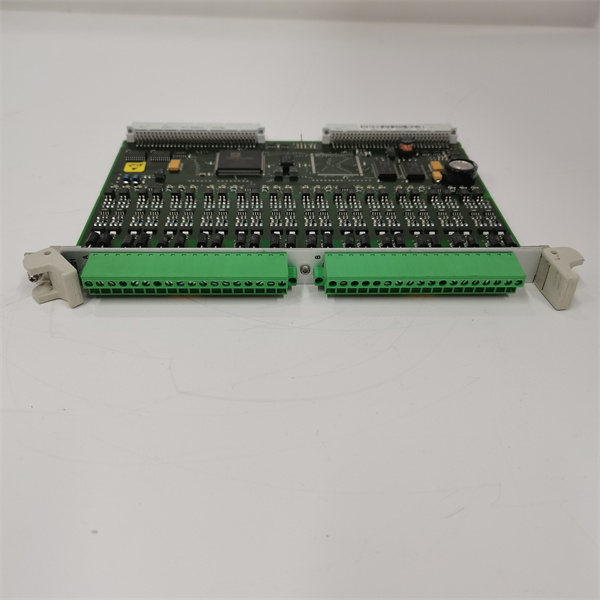

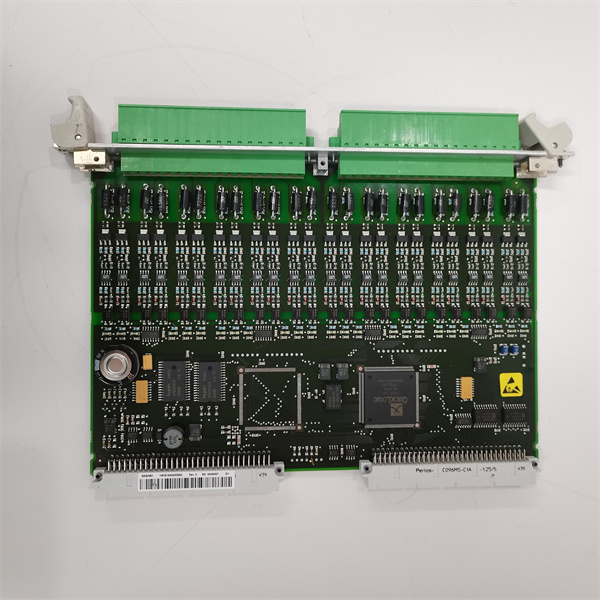

ABB 500BIM01 1MRB160024R0002

The 500BIM01 1MRB160024R0002 is an advanced industrial biological monitoring system from ABB, engineered to deliver comprehensive microbial and organic contaminant analysis in critical process environments. As an upgraded successor to models like the 500BIO01 1MRB150005R1J, 500BIM01 1MRB160024R0002 expands detection capabilities while enhancing connectivity for smart manufacturing ecosystems.

This integrated system combines high-range bacteria detection (0-5000 CFU/mL) with total organic carbon (TOC) measurement, making it ideal for applications ranging from raw water treatment to final product quality control. Unlike conventional single-analyte devices, 500BIM01 1MRB160024R0002 provides a holistic view of process hygiene, enabling proactive contamination management. Its multi-protocol communication suite ensures seamless integration with ABB’s AC500 PLCs and third-party SCADA systems, establishing it as a cornerstone of digital quality management strategies.

Core advantages and technical highlights

Extended detection range with precision: 500BIM01 1MRB160024R0002 offers a 5x wider bacteria detection range compared to the 500BIO01 1MRB150005R1J, reaching up to 5000 CFU/mL—critical for monitoring pre-treatment water sources and wastewater streams. Even at this expanded range, it maintains ±2% accuracy, ensuring reliable results for both low-level product testing and high-level contamination events.

Dual-mode sampling flexibility: The system supports both in-line installation for continuous monitoring and bypass flow configuration for low-pressure applications, such as pharmaceutical pure water loops. This versatility allows 500BIM01 1MRB160024R0002 to adapt to varying process conditions, from high-flow beverage lines to precision injection water systems, without sacrificing measurement integrity.

Smart diagnostics and predictive alerts: 500BIM01 1MRB160024R0002 incorporates advanced algorithms that analyze historical data to predict contamination trends, issuing alerts before thresholds are breached. In a biopharmaceutical facility, this capability can identify declining water quality 2-3 hours earlier than traditional monitors, providing valuable time to implement corrective actions before batch quality is compromised.

Enhanced connectivity for Industry 4.0: With PROFINET and OPC UA support, 500BIM01 1MRB160024R0002 integrates seamlessly into digital networks, enabling centralized data management and remote monitoring. This connectivity allows quality managers to access real-time results from multiple 500BIM01 1MRB160024R0002 units across a facility, streamlining compliance reporting and reducing manual data entry errors.

Typical application scenarios

In biopharmaceutical production, 500BIM01 1MRB160024R0002 monitors bioreactor inlet water and cleaning validation processes. Installed in bypass mode on WFI (Water for Injection) loops, it continuously measures both bacteria levels and TOC, ensuring compliance with USP <1231> and EP 5.1.4. When TOC levels rise above 500 ppb—indicating potential organic contamination—the system triggers an automatic alert via OPC UA to the manufacturing execution system (MES), pausing batch processing until conditions are corrected. This real-time intervention prevents costly product losses and regulatory non-compliance.

In municipal water treatment plants, 500BIM01 1MRB160024R0002 operates in in-line mode to monitor raw water intake and post-disinfection streams. Its wide bacteria range (0-5000 CFU/mL) tracks microbial load through treatment stages, while TOC measurement assesses organic precursor levels that affect disinfection byproduct formation. Data from 500BIM01 1MRB160024R0002 is sent via Modbus to the plant’s SCADA system, enabling automated adjustment of chlorine dosing—reducing chemical usage by up to 15% compared to fixed-schedule dosing.

ABB 500BIM01 1MRB160024R0002

Related model recommendations

500BIM02 1MRB160025R0002: A compact variant of 500BIM01 1MRB160024R0002 with a 0-2000 CFU/mL range, ideal for point-of-use monitoring in pharmaceutical fill-finish areas.

500BIO01 1MRB150005R1J: A predecessor to 500BIM01 1MRB160024R0002 with basic detection capabilities, suitable for budget-conscious applications.

AC500 PLC: ABB’s programmable logic controller that integrates with 500BIM01 1MRB160024R0002 for automated contamination response.

TB857 Surge Protector: Safeguards 500BIM01 1MRB160024R0002’s electronics during washdowns and power transients.

HMI900: ABB’s advanced touchscreen panel that visualizes trends from 500BIM01 1MRB160024R0002 with customizable dashboards.

500CAL-BIM: Calibration kit specific to 500BIM01 1MRB160024R0002, including certified standards for both bacteria and TOC.

FlowKit-BIM: ABB’s flow control accessory that ensures optimal sample conditions for 500BIM01 1MRB160024R0002 in low-flow applications.

Installation, commissioning and maintenance instructions

Installation preparation: For in-line installation, mount 500BIM01 1MRB160024R0002 sensor in a horizontal pipe (≥3-inch diameter) with 15D upstream/5D downstream straight runs. Use 3-A certified tri-clamp fittings (torqued to 18 Nm) for sanitary applications. Connect controller to 24V DC or 110-230V AC power—verify voltage compatibility before wiring. Use shielded Cat 5e cable for PROFINET, grounding shields at both ends. Required tools: sanitary torque wrench, flow meter, and laptop with ABB’s BioSuite software. Flush lines with 0.1N NaOH solution to remove biofilm before sensor installation.

Maintenance suggestions: Calibrate 500BIM01 1MRB160024R0002 bi-weekly using 500CAL-BIM to maintain ±2% accuracy. Clean sensor weekly with ABB-approved enzymatic cleaner to prevent biofouling—avoid bleach or abrasive tools that damage the optical surface. Check flow rates monthly (recommended 0.5-2 L/min) to ensure measurement stability. If response time exceeds 20 seconds, perform a factory reset via BioSuite; replace sensor if issues persist. Document all maintenance in ABB’s ComplianceLog software to meet FDA audit requirements.

Service and guarantee commitment

500BIM01 1MRB160024R0002 comes with a 4-year warranty from installation, covering parts and labor for manufacturing defects. ABB guarantees 2-hour technical support response for critical applications, with on-site service within 48 hours for pharmaceutical and food sectors. The system includes lifetime access to BioSuite software updates and compliance documentation. Extended service contracts offer quarterly calibration, preventive maintenance, and priority technical support, ensuring 500BIM01 1MRB160024R0002 maintains regulatory compliance throughout its 7-year design lifespan. Customers receive dedicated portal access to validation templates, white papers, and training materials specific to this model.