Description

Key Technical Specifications

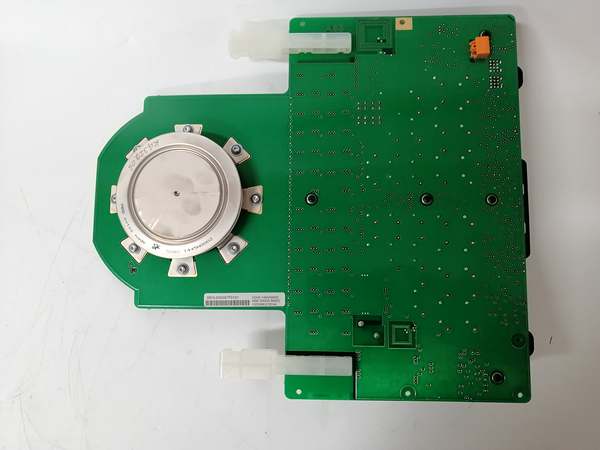

- Model Number: 3BHL000387P0101

- Manufacturer: ABB Robotics Division

- Input Voltage: 24VDC ±10% (from IRC5 controller power supply)

- Output Rating: 3-phase AC (0-480V, 0-15A) for servo motors

- Control Type: Closed-loop vector control (position/velocity/torque modes)

- Communication Interface: IRC5 internal backplane (real-time motion data)

- Operating Temperature: 0°C to +45°C (32°F to +113°F)

- Isolation Rating: 2kV AC (power circuits to control circuits)

- Protection Features: Overcurrent, overvoltage, overtemperature, short-circuit protection

- Mechanical Design: Plug-in module, IRC5 rack-mount (2U height), metal housing (IP20)

- Compatibility: ABB IRC5 Compact/Panel/MultiMove controllers; IRB 120/4600/6700/7600 robot series

- Certifications: CE, UL 508C, RoHS 2.0, IEC 61800-5-1

- Weight: 1.2kg (2.6lbs)

ABB 3BHL000387P0101

Field Application & Problem Solved

In industrial robotics—automotive assembly lines, electronics manufacturing, heavy-duty material handling—robot drive failures cause catastrophic production halts. Generic servo drives lack integration with ABB IRC5 controllers, leading to motion inaccuracies and communication failures. A Michigan auto plant lost $270k in a 6-hour outage when a generic drive failed mid-welding cycle, scrapping 500 vehicle frames. Legacy replacement drives also suffer from poor motion synchronization: a Texas electronics facility experienced 0.5mm positioning errors with off-brand drives, making them unusable for precision assembly.

You’ll find this drive module installed in IRC5 controllers powering ABB robots: IRB 6700 welding robots in automotive body shops, IRB 4600 material handlers in logistics centers, and IRB 7600 heavy-load robots in aerospace component manufacturing. Its core value is ABB-native integration + precision motion control + industrial ruggedness. The closed-loop vector control ensures sub-millimeter positioning accuracy, while direct IRC5 backplane communication eliminates latency between the drive and main CPU. For a Pennsylvania packaging plant, the drive’s overcurrent protection prevented motor burnout during sudden load spikes—something generic drives failed to do, costing $15k in motor replacements annually.

Installation & Maintenance Pitfalls (Expert Tips)

- Wiring Polarity: Match Phase Connections Exactly: Rookies mix up 3-phase motor wiring, causing robot joint jitter or catastrophic motion errors. An Ohio metal fabricator’s IRB 6700 crashed into a workpiece after a drive was miswired. Follow ABB’s color-coded diagram (U=red, V=yellow, W=blue) and verify with a phase rotation tester before powering on.

- Firmware Sync with IRC5 Controller: Outdated drive firmware (pre-v6.5) with IRC5 v7.0+ causes motion control desyncs. A Florida plastics plant’s robot exhibited erratic arm movement until the drive was updated via RobotStudio software. Always match drive firmware to the controller’s version—mismatched versions corrupt motion profiles.

- Cooling Clearance: Maintain 10mm Around Module: Crowded IRC5 racks block airflow, leading to overtemperature shutdowns. A Illinois electronics plant’s drives failed hourly during summer until technicians removed redundant wiring blocking vents. Ensure 10mm of open space around the drive and clean dust filters in the controller monthly.

- Load Testing After Installation: Skip the “power-on and hope” approach. Use RobotStudio’s motion test tool to run the robot through a full range of motion, monitoring drive current draw and temperature. A North Carolina furniture plant missed a faulty drive during installation, leading to a 3-hour outage when it failed during a heavy-load cycle.

ABB 3BHL000387P0101

Technical Deep Dive & Overview

The 3BHL000387P0101 is a dedicated servo drive module engineered to power and control ABB IRC5-controlled robot joints, converting DC input power into precise 3-phase AC for servo motors. At its core, a 32-bit motion processor executes closed-loop vector control algorithms, using feedback from motor encoders to adjust voltage and frequency in real time—this ensures the robot maintains sub-millimeter positioning accuracy even under variable loads. The drive’s integration with the IRC5 backplane allows it to receive motion commands from the main CPU and transmit diagnostic data (current draw, temperature, fault codes) with <1ms latency.

Unlike generic servo drives, this module is calibrated to match the dynamic characteristics of ABB robot motors (e.g., torque curves, inertia values), eliminating motion smoothness issues common with third-party alternatives. It features built-in protection circuits that detect overcurrent (e.g., from a jammed joint) and shut down power within 10ms, preventing motor or drive damage. The plug-in design enables hot-swapping for zero-downtime maintenance—a critical feature for 24/7 manufacturing environments.

What sets it apart is its seamless integration with ABB’s RobotStudio software, allowing technicians to tune motion parameters, monitor drive performance, and troubleshoot faults remotely. For facilities where robot uptime and precision directly impact productivity, this drive module isn’t just a component—it’s a reliable, precision-engineered workhorse that keeps ABB robots operating at peak performance.