Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 3BHE024577R0101 PPC907BE AMC34 |

| Manufacturer | ABB |

| Product category | High-performance processor module for industrial control |

| Processor | Dual-core 64-bit ARM Cortex-A53, 1.2 GHz |

| Memory | 4 GB DDR4 RAM, 16 GB eMMC flash (expandable to 64 GB) |

| Communication interfaces | 2 x Gigabit Ethernet, 1 x USB 3.0, 1 x RS485 |

| Supported protocols | PROFINET IO, EtherNet/IP, Modbus TCP/IP, OPC UA |

| I/O processing capacity | Up to 8192 digital points, 2048 analog points |

| Operating system | ABB Automation OS (based on Linux) |

| Operating voltage | 24 V DC ±15% |

| Power consumption | Max 15 W |

| Operating temperature | -40°C to 70°C |

| Protection rating | IP20 |

| Mounting type | Backplane mount (compatible with AC800M/S800 series) |

| Dimensions | 140mm × 180mm × 90mm |

| Certifications | CE, UL, ATEX, IEC 61131-2, IEC 61508 (SIL 2) |

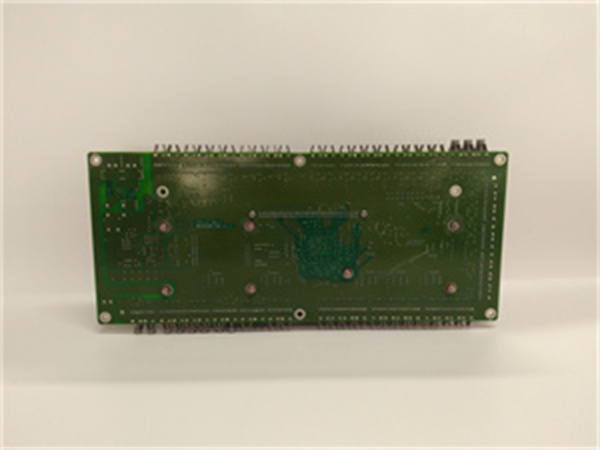

ABB 3BHE024577R0101 PPC907BE AMC34

Product introduction

The 3BHE024577R0101 PPC907BE AMC34 is a high-performance processor module from ABB, designed to serve as the central processing unit in advanced industrial control systems. As a flagship component in ABB’s automation portfolio, this module integrates powerful computing capabilities with versatile communication features, enabling it to handle complex control tasks while seamlessly interacting with network components like the CI930F 3BDH001010R0005 communication interface and field devices such as the DSDP140B digital input module.

Unlike basic PLC processors, the PPC907BE AMC34 combines real-time control with edge computing functionality, making it ideal for applications requiring both deterministic operation and data analytics. Whether deployed in large-scale process plants, smart manufacturing facilities, or critical infrastructure systems, this module delivers the processing power to execute advanced control algorithms, manage distributed I/O networks, and support integration with cloud-based monitoring platforms.

Core advantages and technical highlights

Dual-core processing power: Equipped with a 1.2 GHz dual-core ARM Cortex-A53 processor, the 3BHE024577R0101 PPC907BE AMC34 delivers exceptional computing performance for both real-time control and data processing tasks. In a chemical plant, this allows the module to simultaneously execute complex PID control loops for reactor temperature regulation (with cycle times as low as 1 ms) and run machine learning algorithms to predict equipment degradation—all without compromising control accuracy. The 4 GB DDR4 RAM ensures smooth multitasking, even when handling thousands of I/O points.

Advanced communication integration: With dual gigabit Ethernet ports and support for protocols like PROFINET IO and EtherNet/IP, the module seamlessly connects to communication interfaces such as the CI930F 3BDH001010R0005, enabling high-speed data exchange with distributed field devices. Its OPC UA compatibility facilitates secure communication with enterprise systems and cloud platforms, making it a key component in Industry 4.0 implementations. In an automotive factory, this allows the processor to transmit production metrics to a cloud-based MES system while receiving real-time equipment status data from SNAT634PAC safety controllers via PROFIsafe.

Edge computing capabilities: Running on ABB’s Automation OS (a Linux-based platform), the PPC907BE AMC34 supports custom applications and third-party software, enabling edge analytics and localized decision-making. In a logistics center, it can process data from UAD154A analog modules monitoring conveyor belt loads, applying predictive algorithms to optimize energy usage and prevent jams—all without relying on a central server. This reduces network traffic and ensures rapid response to local events.

Robust reliability: The module operates reliably in extreme temperatures (-40°C to 70°C) and features extensive fault tolerance, including watchdog timers, voltage monitoring, and ECC (Error-Correcting Code) memory. Its SIL 2 certification makes it suitable for safety-related applications, such as monitoring critical pressure sensors in oil refineries. The rugged design, including conformal coating on circuit boards, protects against dust, vibration, and electromagnetic interference, ensuring uninterrupted operation in harsh industrial environments.

Scalable I/O handling: With the capacity to process up to 8192 digital and 2048 analog points, the 3BHE024577R0101 scales from medium-sized machines to large plant-wide systems. It supports hot-swappable I/O modules, allowing expansion or maintenance without system shutdown—a critical feature in continuous processes like water treatment. When paired with the CI930F 3BDH001010R0005, it can manage geographically distributed I/O networks, extending control capabilities across multiple production areas.

Typical application scenarios

In a combined cycle power plant, the 3BHE024577R0101 PPC907BE AMC34 serves as the main controller for a gas turbine system. It processes data from hundreds of sensors (via UAD154A modules) measuring temperature, pressure, and vibration, executing advanced control algorithms to optimize fuel efficiency and reduce emissions. The module communicates with CI930F 3BDH001010R0005 interfaces to coordinate with steam turbine controls and grid synchronization systems, ensuring stable power output. Its edge computing capabilities analyze operational trends to predict maintenance needs, reducing unplanned downtime by up to 20%.

In a smart factory producing electronic components, the processor manages a flexible manufacturing line with robotic assembly cells, automated guided vehicles (AGVs), and vision inspection systems. It synchronizes motion control via DSMC112 servo controllers (connected through CI930F), adjusts production schedules based on real-time order data, and uses machine vision inputs (from DSDP140B modules) to detect defects. The OPC UA interface streams production data to a cloud dashboard, providing plant managers with visibility into key metrics like throughput and yield—all while maintaining sub-millisecond control cycle times for precise component placement.

ABB 3BHE024577R0101 PPC907BE AMC34

Related model recommendations

3BHE024578R0101 PPC908BE AMC35: A higher-performance variant with a quad-core processor and 8 GB RAM, ideal for data-intensive applications requiring advanced analytics.

CI930F 3BDH001010R0005: ABB’s PROFINET IO controller that connects the PPC907BE AMC34 to distributed field devices.

SNAT634PAC: ABB’s safety controller that integrates with the processor for safety-critical functions via PROFIsafe.

DSDP140B: ABB’s digital input module whose data is processed by the 3BHE024577R0101 for discrete control tasks.

UAD154A 3BHE026866R0101: ABB’s analog input module that provides continuous process data to the processor.

XC208: ABB’s managed Ethernet switch that enhances network reliability between the processor and communication interfaces.

HMI80: ABB’s advanced touchscreen panel that visualizes real-time data and control interfaces from the PPC907BE AMC34.

Installation, commissioning and maintenance instructions

Installation preparation: Mount the 3BHE024577R0101 PPC907BE AMC34 into a compatible backplane (e.g., AC800M) using the front-panel locking mechanism, torquing screws to 0.8 Nm. Ensure at least 100mm clearance for ventilation to dissipate heat. Connect to a 24 V DC power supply (3A minimum) with redundant feeds for critical applications, using 1.5mm² shielded cable and a 5A fuse. Attach Ethernet cables (Cat 6a) to the gigabit ports for network connectivity, and RS485 for legacy devices. Required tools include a torque screwdriver, wire strippers, and a laptop with ABB’s Automation Builder software. Power off the system during installation.

Configuration steps: Use Automation Builder to configure the processor’s network settings (IP address, subnet), control logic (via IEC 61131-3 languages), and communication mappings with connected devices (e.g., CI930F 3BDH001010R0005, SNAT634PAC). Deploy custom edge applications via the Linux command line or ABB’s Application Manager. Perform a functional test by simulating process inputs and verifying control outputs, ensuring cycle times meet application requirements (<5 ms for critical loops). Back up the configuration to external storage and enable automatic backups to the module’s eMMC flash.

Maintenance suggestions: Inspect the module quarterly for loose connections, dust accumulation, and LED status (power: solid green, fault: red, communication: flashing green). Clean ventilation grilles with compressed air to prevent overheating. Monitor processor load via the HMI or web interface—sustained loads above 70% may require optimization. Update firmware and OS annually via secure Ethernet, scheduling updates during planned downtime. Check memory usage monthly to ensure sufficient capacity for running applications. If hardware faults occur (e.g., uncorrectable memory errors), replace with an ABB-certified module to maintain performance and safety certifications.

Service and guarantee commitment

The 3BHE024577R0101 PPC907BE AMC34 comes with a 5-year warranty from installation, covering manufacturing defects and ensuring compliance with published performance specifications. ABB guarantees technical support response within 4 hours for critical applications, with on-site service available in 72 hours for qualified industrial facilities. The module includes free access to Automation Builder software and OS/firmware updates for 3 years. Extended service contracts offer annual preventive maintenance, performance tuning, and priority support, ensuring the processor maintains reliable operation throughout its 15-year design lifespan. Customers receive dedicated online resources, including programming guides, compatibility matrices, and troubleshooting manuals specific to this model.