Description

Key Technical Specifications

- Model Number: ABB UNS2881B-PV1 3BHE009319R0001

- Manufacturer: ABB Power Automation Division

- Output Rating: 24VDC ±0.5%, 10A continuous; 12A peak (10-minute max)

- Input Voltage: Dual 110/220V AC/DC ±15% (switch-selectable per input channel)

- Redundancy Support: 1+1 hot-standby (with dual units), automatic failover <5ms

- Protection Features: Short-circuit (auto-reset, 15A trip), overload (120% capacity shutdown), overtemperature (75°C cutoff), reverse polarity protection

- Power Efficiency: ≥90% at full load; ≥86% at 20% load

- Operating Temperature: -25°C to +65°C (-13°F to +149°F)

- Isolation Rating: 2kV AC (input to output); 500V AC (output to chassis)

- Certifications: IEC 61010-1, CE, UL 508, ATEX Zone 2, RoHS 2.0

- Compatibility: ABB Symphony Plus DCS racks, 3BHE series controllers (PCD235B101), Control Builder M software

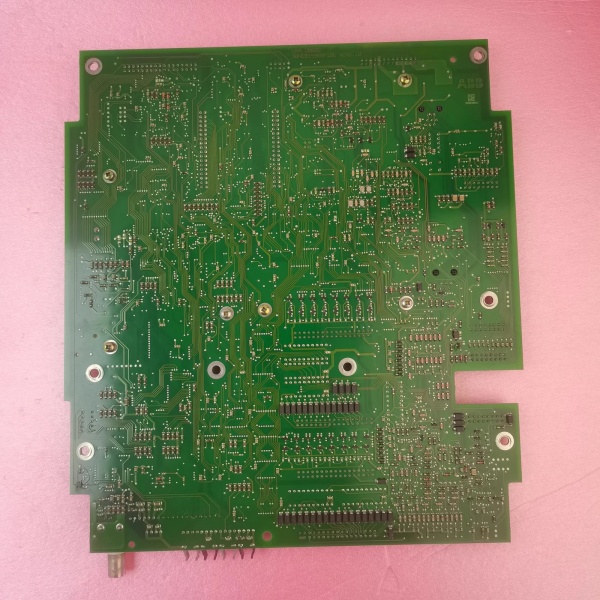

- Mechanical Design: Rack-mount (3U height), metal chassis, conformal-coated PCB (IP20)

- Status Monitoring: LED indicators (power on, fault, overload); backplane alarm output (4-20mA)

UNS2881B-PV1 3BHE009319R0001

Field Application & Problem Solved

In critical process environments—coal/gas-fired power plants, oil refineries, chemical batch facilities—DCS power supply failures are catastrophic, and generic units lack the redundancy and ruggedness to survive. A Pennsylvania coal plant lost $1.7M in a 10-hour outage when a single-point generic power supply failed, shutting down the boiler control system and triggering a full plant shutdown. Legacy units also force compromise: a Louisiana refinery used two separate non-redundant supplies for their Symphony Plus DCS, leading to 2 hours of monthly downtime from manual switchovers during maintenance.

You’ll find this module in Symphony Plus DCS racks powering mission-critical components: turbine control systems in Texas gas plants, reactor temperature controllers in Ohio chemical facilities, and distillation column I/O modules in Louisiana refineries. Its core value is fault-tolerant redundancy + ABB-native reliability + industrial ruggedness. The dual-input, hot-standby-capable design eliminated the Pennsylvania plant’s single-point failures—zero unplanned outages in 4 years. At the Louisiana refinery, the integrated redundancy replaced two generic units, cutting maintenance downtime by 90% and saving $24k annually.

For a North Sea offshore platform, the module’s conformal coating withstood salt spray and humidity that destroyed three generic supplies in 18 months. Its wide input voltage range (110/220V AC/DC) also simplified integration with the platform’s dual-power grid, avoiding $30k in transformer costs.

Installation & Maintenance Pitfalls (Expert Tips)

- Dual Inputs Must Use Separate Power Sources: Rookies wire both input channels to the same UPS, defeating redundancy. A Florida chemical plant did this; a UPS failure took down the DCS, causing a 3-hour reactor shutdown. Feed Input 1 from the plant’s main UPS and Input 2 from an emergency backup generator—verify with a multimeter that both sources are active before commissioning.

- Input Voltage Selection: Set Both Channels: Forgetting to switch both input channels to match the plant’s voltage (110/220V) fries the internal rectifier. A Michigan paper mill ruined one module ($600) by setting Input 1 to 220V but leaving Input 2 at 110V. Use the module’s internal DIP switches to configure both inputs, and label the settings clearly for future maintenance.

- Thermal Clearance: 50mm Minimum—No Exceptions: Blocking airflow around the module’s vents causes overtemperature shutdowns. A Colorado mining facility stacked I/O modules directly above it, leading to daily failures during summer peak load. Maintain 50mm clearance on all sides, avoid mounting near VFDs or power resistors, and use thermal imaging to confirm case temps stay <60°C at full load.

- Firmware Mismatch Breaks Redundancy Sync: Outdated module firmware (pre-v7.0) with Symphony Plus v8.0+ causes failover communication errors. A Texas petrochemical plant had intermittent power glitches until updating the UNS2881B-PV1 to v8.1. Use ABB’s Service Port to update firmware, and verify redundancy sync via the DCS diagnostics—look for <5ms failover time.

UNS2881B-PV1 3BHE009319R0001

Technical Deep Dive & Overview

The ABB UNS2881B-PV1 3BHE009319R0001 is a purpose-built redundant power supply module engineered exclusively for ABB’s Symphony Plus DCS, designed to deliver uninterrupted power in harsh industrial environments. At its core, a high-efficiency switch-mode converter converts dual 110/220V AC/DC inputs to regulated 24VDC output, maintaining ±0.5% voltage accuracy—critical for sensitive DCS components like controllers and I/O modules.

Redundancy logic is handled by a dedicated 16-bit microcontroller that monitors both input channels and output load in real time. If one input fails or the module detects an overload/overtemperature, the controller automatically switches to the secondary input (or standby module, in 1+1 config) in <5ms—faster than the DCS’s voltage dropout tolerance, ensuring no process disruption.

Protection circuits are layered for industrial resilience: auto-reset short-circuit protection clamps current to 15A to prevent wire damage, while overtemperature shutdown (75°C) protects internal components from thermal degradation. The conformal-coated PCB repels dust, moisture, and chemical vapors—essential for refineries (corrosive hydrocarbons) and coal plants (fly ash).

Unlike generic power supplies, this module is factory-calibrated to integrate seamlessly with Symphony Plus DCS racks, requiring no custom wiring or programming. The backplane alarm output transmits real-time status data to the DCS, enabling predictive maintenance (e.g., alerting to declining input voltage before a failure). For facilities where downtime costs $20k+/minute, this module isn’t just a power supply—it’s a critical safety net that keeps control systems running, even when one power source fails.