Description

Product Overview

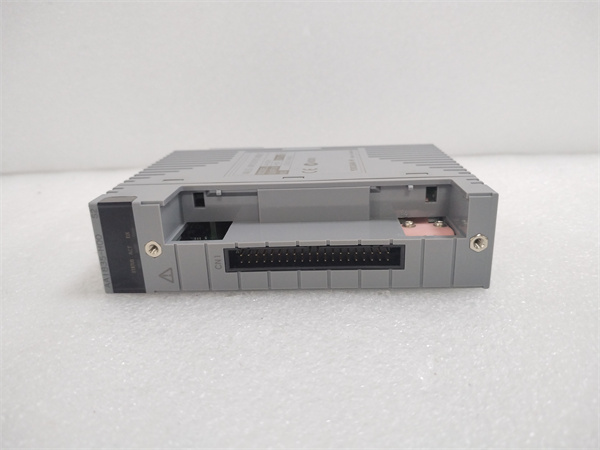

The YOKOGAWA AAI835-H50 is a high-performance analog input module designed for integration into industrial automation and distributed control systems (DCS). As part of Yokogawa’s extensive I/O module lineup, the AAI835-H50 delivers precise signal acquisition, robust reliability, and seamless compatibility with Yokogawa’s CENTUM VP and ProSafe-RS control platforms. This module is engineered to handle analog signals from field instruments, ensuring accurate data conversion and transmission to the control system for real-time monitoring and process optimization.

The YOKOGAWA AAI835-H50 supports multiple input types, including current (4–20 mA) and voltage (1–5 V) signals, making it versatile for various industrial applications. Its high channel density and isolation capabilities minimize interference, ensuring stable operation even in electrically noisy environments. Designed for mission-critical processes, the AAI835-H50 enhances system reliability with built-in diagnostics and hot-swappable functionality, reducing downtime during maintenance. Whether deployed in oil & gas, chemical, or power generation plants, this module ensures seamless integration and long-term performance in demanding industrial environments.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | AAI835-H50 |

| Manufacturer | YOKOGAWA |

| Product Type | Analog Input Module |

| Input Channels | 8 channels |

| Signal Type | 4–20 mA, 1–5 V DC (selectable per channel) |

| Isolation | Channel-to-channel and channel-to-system isolation |

| Accuracy | ±0.1% of span |

| Conversion Speed | 100 ms per channel (typical) |

| Operating Temperature | -20°C to +60°C |

| Power Supply | 24 V DC (nominal) |

| Communication Protocol | Yokogawa proprietary (compatible with CENTUM VP) |

| Mounting | DIN rail or panel mount |

| Dimensions | 45 mm (W) × 130 mm (H) × 120 mm (D) |

YOKOGAWA AAI835-H50

Main Features and Advantages

The YOKOGAWA AAI835-H50 stands out due to its high precision, rugged construction, and advanced diagnostic capabilities. Each channel is individually isolated, preventing cross-talk and ensuring signal integrity even in harsh industrial environments. The module supports flexible signal configuration, allowing users to mix current and voltage inputs as needed, which simplifies system design and reduces spare part requirements.

Hot-swappable design ensures minimal disruption during maintenance, enabling module replacement without shutting down the entire control system. Built-in diagnostics provide real-time monitoring of signal health, detecting issues such as open circuits or out-of-range signals before they impact operations. The AAI835-H50 is fully compatible with Yokogawa’s CENTUM VP DCS, ensuring seamless integration and simplified engineering workflows. Its compact form factor and DIN rail mounting option make it ideal for space-constrained installations while maintaining high reliability in extreme temperatures and high-noise environments.

Application Field

The YOKOGAWA AAI835-H50 is widely used in industries requiring high-precision analog signal acquisition and robust control system integration. In oil & gas refineries, it monitors critical process variables such as pressure, temperature, and flow rates, ensuring safe and efficient operations. Chemical plants benefit from its high isolation and accuracy, enabling precise control of reaction processes and batch operations.

Power generation facilities rely on the AAI835-H50 for real-time monitoring of turbine sensors and grid stability parameters. Water and wastewater treatment plants use this module to track pH levels, dissolved oxygen, and pump performance, ensuring regulatory compliance and process efficiency. Its rugged design and diagnostic capabilities make it suitable for hazardous areas and remote installations where reliability is paramount.

YOKOGAWA AAI835-H50

Related Products

-

AAI835-S50: Similar to the AAI835-H50 but with screw terminal connections for enhanced vibration resistance.

-

AAI143: A 16-channel analog input module for higher-density applications.

-

AAI543: A high-speed analog input module with faster sampling rates.

-

AAI831: A lower-channel-count variant (4 channels) for cost-sensitive installations.

-

ASI143: Analog output module for complementary control signal generation.

-

ADM11B: Signal conditioner for interfacing with legacy field devices.

Installation and Maintenance

Pre-installation preparation: Before installing the YOKOGAWA AAI835-H50, verify compatibility with the existing control system and ensure proper power supply specifications. Check for any firmware updates and confirm grounding requirements to prevent electrical noise interference.

Maintenance recommendations: Regularly inspect the module for environmental stress, such as dust or moisture ingress. Utilize the built-in diagnostics to monitor signal health and replace faulty channels as needed. When performing maintenance, follow Yokogawa’s guidelines for hot-swapping to avoid system disruptions.

Product Guarantee

Yokogawa guarantees the AAI835-H50 for high reliability and long-term performance, backed by a standard warranty covering manufacturing defects. Customers receive access to global technical support, including troubleshooting assistance and firmware updates. With Yokogawa’s commitment to quality, the AAI835-H50 is designed to meet stringent industrial standards, ensuring years of trouble-free operation in critical automation applications.