Description

Product Overview

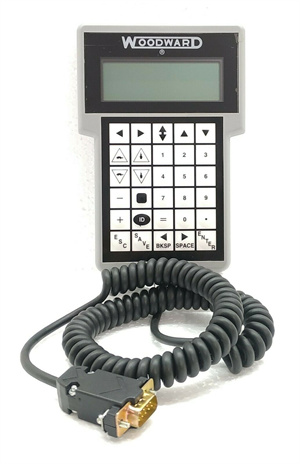

The Woodward 9907-205 is a high-performance digital speed control system designed for industrial turbines, reciprocating engines, and critical rotating machinery. As part of Woodward’s 9900 series of precision control solutions, this ruggedized module delivers ±0.1% speed regulation accuracy with adaptive control algorithms optimized for demanding applications in power generation, marine propulsion, and oil & gas. The 9907-205 features a stainless steel enclosure (IP66) capable of withstanding extreme environments (-40°C to +85°C, 5G vibration), making it suitable for offshore platforms, arctic installations, and high-vibration industrial sites. With dual-redundant communication networks (CANbus and Modbus RTU) and IEC 62443 cybersecurity features, this controller ensures reliable operation while protecting against modern cyber threats. The module’s advanced diagnostics and predictive maintenance capabilities provide early warning of potential system issues, reducing unplanned downtime.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | 9907-205 |

| Manufacturer | Woodward |

| Product Type | Digital Speed Controller |

| Control Accuracy | ±0.1% of setpoint |

| Speed Range | 20-20,000 RPM (software configurable) |

| Input Signals | 2× MPU (1-20kHz), 4× 4-20mA, 2× RTD |

| Output Signals | ±200mA servo, 4× 4-20mA, 4× relay |

| Control Algorithms | Adaptive PID, Droop, Baseload |

| Response Time | <50ms (10-90% stroke) |

| Communication | Dual CANbus, Modbus RTU |

| Power Supply | 24V DC (18-36V) or 120V AC (85-264V) |

| Power Consumption | 10W typical |

| Operating Temp. | -40°C to +85°C |

| Vibration Resistance | 5G (10-500Hz) |

| Protection Rating | IP66 (NEMA 4X) |

| Certifications | UL, CE, DNV-GL |

WOODWARD 9907-205

Main Features and Advantages

Adaptive control technology: The Woodward 9907-205 features self-tuning PID algorithms that automatically adjust to changing system dynamics, maintaining optimal performance across the entire operating range. Its Load Feedforward function anticipates load changes for smoother transitions.

Robust construction: The module’s stainless steel housing and conformal-coated electronics provide exceptional resistance to humidity, salt spray, and chemical exposure. Military-grade connectors ensure reliable signal transmission in high-vibration environments.

Comprehensive diagnostics: Built-in vibration monitoring via speed sensor inputs enables early detection of mechanical issues. The 9907-205 provides ISO 13374-compliant health reports and maintenance alerts based on performance trends.

Flexible integration: Supports CANopen and J1939 protocols for seamless connection to modern control systems while maintaining compatibility with legacy Woodward equipment. The dual communication ports allow daisy-chaining of multiple devices.

WOODWARD 9907-205

Application Field

The Woodward 9907-205 excels in critical speed control applications:

Gas Turbines: Precise speed regulation for power generation

Pipeline Compressors: Anti-surge control system integration

Marine Engines: Main propulsion and auxiliary generator control

Industrial Drives: Large compressor and pump control

Cogeneration Plants: Combined heat and power optimization

Related Products

9907-206: Marine-certified version with additional I/O

9907-204: Basic version without communications

ProAct Power: Centralized control system

EGB-700: Emergency backup governor

UG-10: Hydraulic actuator for valve control

L-Series MPUs: High-reliability speed sensors

Installation and Maintenance

Pre-installation preparation: Verify sensor compatibility and actuator specifications before wiring. Implement proper grounding (<1 ohm) for noise immunity. Configure communication parameters prior to system startup.

Maintenance recommendations: Perform annual control loop analysis using Woodward’s TuneMaster software. Monitor component temperatures via embedded diagnostics. Update firmware during planned maintenance windows. The 9907-205 supports module replacement without system shutdown.

Product Guarantee

Woodward offers a 5-year warranty for the 9907-205, covering all electronic components and firmware. Each unit undergoes:

500-hour burn-in testing

Full functional validation at temperature extremes

Vibration testing to 5G

The Platinum Support Program includes:

24/7 technical assistance

Lifetime firmware updates

15-year spare parts availability

NIST-traceable recalibration services