Description

Product Overview

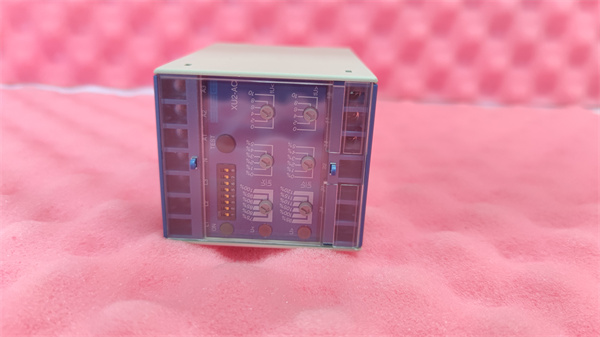

The Woodward XU2-AC is a high-performance actuator control module designed for precise regulation of fuel, steam, or gas in turbine and engine management systems. As part of Woodward’s XU series, this advanced control unit provides reliable, real-time actuator positioning for industrial power generation, marine propulsion, and oil & gas applications.

Engineered for demanding environments, the Woodward XU2-AC delivers high-accuracy positioning (±0.1% full scale) and fast response times (<50ms) to maintain optimal process control. Its rugged construction withstands extreme temperatures, vibration, and electromagnetic interference, making it suitable for installation in harsh industrial settings. The module integrates seamlessly with Woodward’s ProAct™ and NetCon™ control platforms, offering flexible configuration options through intuitive software tools.

With its dual-channel redundancy and self-diagnostics, the Woodward XU2-AC ensures uninterrupted operation in critical applications where system reliability is paramount.

Technical Specifications

| Parameter Name | Parameter Value |

| Model Number | XU2-AC |

| Manufacturer | Woodward |

| Product Type | Actuator Control Module |

| Input Voltage | 20–30 VDC (24V nominal) |

| Output Current | 0–20 mA (configurable) |

| Control Accuracy | ±0.1% full scale |

| Response Time | <50 ms |

| Operating Temp. | -40°C to +85°C (-40°F to +185°F) |

| Communication | CANbus 2.0B, Modbus RTU (RS-485) |

| Protection Rating | IP40 (front), IP20 (housing) |

| Dimensions | 120 x 90 x 45 mm (4.7 x 3.5 x 1.8 in) |

| Weight | 0.8 kg (1.76 lbs) |

woodward XU2-AC

Main Features and Advantages

Precision Control

The Woodward XU2-AC provides closed-loop feedback control with 0.1% positioning accuracy, ensuring optimal actuator response for fuel valves, steam turbines, and other critical process controls.

Redundancy & Fault Tolerance

Dual-channel control with automatic failover for uninterrupted operation.

Self-diagnostics detect and log faults, enabling predictive maintenance.

Flexible Integration

CANbus 2.0B and Modbus RTU support seamless communication with PLCs, DCS, and SCADA systems.

Compatible with Woodward ProAct™ for centralized turbine management.

Robust Construction

Marine-grade components resist corrosion and vibration.

Wide temperature operation (-40°C to +85°C) for extreme environments.

woodward XU2-AC

Application Field

The Woodward XU2-AC is widely used in:

Power Generation: Controls fuel and steam valves in gas/diesel turbines.

Marine Propulsion: Manages actuator positioning in ship engines.

Oil & Gas: Regulates flow control valves in compressor stations.

Industrial Processes: Ensures precise motion control in heavy machinery.

Related Products

XU3-AC: Enhanced version with triple redundancy.

ProAct XT 8440-1620: Integrated turbine control system.

NetCon 5000: Networked control platform for actuator systems.

EGCP-3: Standalone governor controller compatible with XU2-AC.

Installation and Maintenance

Installation: Mount on a vibration-damped surface using Woodward-supplied hardware. Ensure proper grounding and shielded cabling for noise immunity.

Maintenance: Perform calibration checks annually using Woodward Toolkit™ software. Inspect terminals for corrosion and verify firmware updates.

Product Guarantee

Woodward offers a 24-month warranty for the XU2-AC, covering defects in materials and workmanship. Global technical support includes 24/7 troubleshooting and firmware updates. The module’s MTBF exceeds 100,000 hours, ensuring long-term reliability.