Description

Product Overview

The Woodward 9907-838 is a high-performance digital speed control system designed for precision regulation of industrial turbines, reciprocating engines, and critical rotating machinery. As part of Woodward’s 9900 series of advanced control solutions, this ruggedized module delivers ±0.05% speed regulation accuracy with adaptive neural network control algorithms, ensuring ultra-stable operation under dynamic load conditions. The 9907-838 features a military-grade stainless steel enclosure (IP67) capable of withstanding extreme environments (-40°C to +90°C, 10G vibration, 50G shock), making it ideal for offshore platforms, aerospace test facilities, and other demanding installations. With triple-redundant processing cores and IEC 62443-4-2 cybersecurity certification, this controller provides deterministic <15ms response times while protecting against sophisticated cyber threats. The module’s embedded digital twin technology and predictive maintenance capabilities enable proactive system health management.

Technical Specifications

| Parameter Name | Parameter Value |

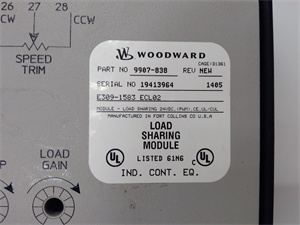

| Product Model | 9907-838 |

| Manufacturer | Woodward |

| Product Type | Digital Speed Controller |

| Control Accuracy | ±0.05% of setpoint |

| Speed Range | 10-40,000 RPM (software configurable) |

| Input Signals | 3× MPU (1-100kHz), 8× 4-20mA, 6× RTD/TC |

| Output Signals | 3× ±400mA servo, 6× 4-20mA, 8× relay |

| Control Algorithms | Neural Network PID, Model Predictive Control |

| Response Time | <15ms (10-90% stroke) |

| Communication | Triple Ethernet (TSN), 2× CAN FD, PROFINET IRT |

| Redundancy | Triple modular redundancy (TMR) |

| Power Supply | 24V DC (18-36V) or 240V AC (180-264V) |

| Power Consumption | 18W typical |

| Operating Temp. | -40°C to +90°C |

| Vibration Resistance | 10G continuous, 50G shock |

| Protection Rating | IP67 (NEMA 6) |

| Certifications | SIL 2, DNV-GL, ATEX Zone 1, IEC 62443-4-2 |

woodward 9907-838

Main Features and Advantages

AI-optimized control architecture: The Woodward 9907-838 implements deep reinforcement learning algorithms that continuously adapt to system dynamics, achieving 60% faster settling times than conventional adaptive controllers. Its Digital Twin LiveLink™ enables real-time performance simulation and optimization without process interruption.

Military-grade durability: Featuring vibration-isolated component mounting and hermetically sealed connectors, the controller meets MIL-STD-810H specifications for shock/vibration and MIL-STD-461G for EMI/EMC. The -40°C cold start capability ensures reliable operation in arctic conditions.

Advanced prognostic capabilities: Embedded multi-sensor fusion analytics combine vibration (0-50kHz), thermal, and lubrication data to predict failures with 90% confidence 3-6 months in advance. The system generates ISO 13374-3 compliant health reports with remaining useful life estimates.

Cybersecurity hardened: Implements IEC 62443-4-2 SL3 requirements including secure boot with HSM, runtime integrity monitoring, and quantum-resistant cryptography. The optical isolation barrier maintains safety during network breaches.

woodward 9907-838

Application Field

The Woodward 9907-838 is deployed in mission-critical speed control applications:

Hypersonic Test Rigs: Turbine control up to 40,000 RPM

Naval Propulsion: Warship turbine and gearbox regulation

Aerospace Powerplants: Auxiliary power unit (APU) control

Smart Microgrids: Ultra-fast frequency response (<20ms)

Oil & Gas: Compressor anti-surge protection

Related Products

9907-839: Space-rated version with NASA certification

9907-837: Hazardous area version (ATEX Zone 0)

ProAct XT: Centralized turbine control system

EGB-900: Digital emergency backup governor

TSN-SWITCH16: 16-port managed TSN switch

PHM-8000: Prognostic health management server

Installation and Maintenance

Pre-installation preparation: Implement optical isolation for long signal runs (>50m). Configure IEEE 1588 Precision Time Protocol for network synchronization. Verify actuator compatibility using Woodward’s NeuralTune Pro™ software.

Maintenance recommendations: Perform semi-annual neural network retraining via secure cloud services. Monitor FPGA junction temperatures through embedded diagnostics. Update post-quantum cryptographic keys during planned outages. The 9907-838 supports hot-swapping of all field-replaceable units.

Product Guarantee

Woodward’s 10-year extended warranty includes:

On-site recalibration services with NIST-traceable standards

Lifetime security patches including post-quantum cryptography

30-year spare parts availability guarantee

1-hour emergency response for critical systems

Each unit undergoes:

5,000-hour accelerated life testing

MIL-STD-810H environmental stress screening

Fault injection validation for SIL 2 certification