Description

9907-345: Product Overview

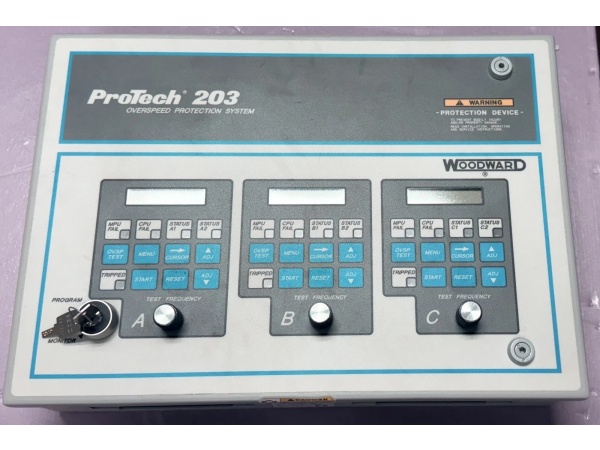

The 9907-345 functions as a dedicated safety instrumented system (SIS) within Woodward’s ProTech 203 series, specifically engineered to prevent catastrophic damage to high-speed rotating machinery from overspeed events. In the protection system hierarchy, this unit represents the primary safety layer—the final defense against mechanical failure when speed control systems malfunction or load is suddenly lost.

Positioned typically in turbine control panels, skid-mounted enclosures, or machinery compartments, the 9907-345 operates as a standalone protection device requiring only 24 VDC power and magnetic pickup speed signals to implement complete overspeed protection. Its microprocessor-based architecture continuously monitors turbine rotor speed through three independent magnetic pickup (MPU) sensors, executing 2-out-of-3 voting logic to ensure that a single sensor failure cannot cause either a spurious trip or a failure to trip. This redundancy architecture aligns with SIL (Safety Integrity Level) requirements for critical machinery protection.

The module’s primary role is speed monitoring and emergency trip execution. Each of the three speed-sensing channels processes MPU signals to calculate rotational speed, comparing measured values against configurable trip setpoints (typically 110-115% of rated speed). When two of three channels confirm an overspeed condition, or when signal loss indicates sensor failure in a 2-out-of-2 configuration, the module immediately de-energizes its six voter relays to initiate emergency shutdown. The de-energize-to-trip (DET) logic ensures that loss of control power, internal faults, or wiring failures result in a safe (tripped) state rather than a dangerous failure mode.

As a recent revision of the ProTech 203 platform, the 9907-345 incorporates enhancements for improved reliability and maintainability. The 24 VDC power input allows integration with standard industrial control power systems and battery-backed UPS architectures common in critical applications. The hot replacement capability enables subsystem replacement without tripping the prime mover (when properly de-energized), reducing maintenance downtime. Individual CPU status LEDs for each speed-sensing unit provide immediate diagnostic visibility, accelerating troubleshooting during commissioning or after fault events.

The lockable, IP54/NEMA 4X enclosure ensures physical security and environmental protection for outdoor or harsh industrial installations. The unit is functionally identical to part number 8200-201, providing procurement flexibility for spare parts management.

Woodward 8200-203

9907-345: Technical Specifications

-

Model Number: 9907-345

-

Identical Part Number: 8200-201

-

Manufacturer: Woodward Inc.

-

Product Type: ProTech 203 Overspeed Protection System

-

System Family: Woodward ProTech 203 Series

-

Functional Description: Overspeed Protection Device

-

Input Power: 24 VDC (18-32 VDC range)

-

Power Consumption: <50 W typical

-

Speed Sensing: Triple-redundant magnetic pickup (MPU) inputs

-

MPU Input Range: 1-30 VAC or 0.5-30 VDC, 250 Hz to 25 kHz frequency range

-

MPU Failed Timeout Range: 100 RPM to 25,000 RPM

-

Speed Calculation: Microprocessor-based with digital filtering

-

Trip Logic: 2-out-of-3 voting (configurable to 2-out-of-2)

-

Trip Setpoint Range: 100-200% of rated speed (configurable)

-

Trip Accuracy: ±0.1% of setpoint

-

Trip Response Time: <40 ms from speed exceedance to relay operation

-

Trip Relay Outputs: 6 voter relays (2 per speed-sensing unit), Form C (SPDT)

-

Relay Contact Rating: 5 A @ 250 VAC/30 VDC resistive

-

Relay Logic: De-energize-to-trip (DET) – failsafe on loss of power

-

Analog Output: 4-20 mA speed signal for external indication

-

Discrete Inputs: Start/reset, test enable, remote reset

-

Discrete Outputs: Alarm, status, relay driver signals

-

Communication: RS-232/RS-485 for configuration and monitoring (optional)

-

Display: LCD with 2-4 lines, 16-20 characters per line

-

Keypad: 6-8 button membrane keypad for local configuration

-

Indicators: CPU status LEDs for each speed-sensing unit; visual and audible alarms

-

Configuration: Front panel or Woodward ProTech software

-

Event Recording: 100-event buffer with timestamp and speed data

-

Self-Diagnostics: CPU failure indication, continuous monitoring of MPU health, relay status, processor integrity

-

Special Features: Hot replacement capability (with power disconnected), key-lock security

-

Enclosure: IP54, NEMA 4/4X, lockable with key switch

-

Mounting: Panel mount or 19″ rack mount

-

Operating Temperature: -25°C to +60°C (-13°F to +140°F) display; -40°C to +70°C internal

-

Storage Temperature: -40°C to +85°C (-40°F to +185°F)

-

Relative Humidity: 5% to 95%, non-condensing

-

Vibration Resistance: 1.0 G, 5-2000 Hz per IEC 60068-2-6

-

Shock Resistance: 15 G, 11 ms half-sine per IEC 60068-2-27

-

EMC Compliance: IEC 61000-4-2 (ESD), IEC 61000-4-4 (EFT), IEC 61000-4-5 (surge)

-

Dimensions: 19.0″ W × 12.244″ H × 5.62″ D (483 × 311 × 143 mm)

-

Weight: <14 lbs (<6.35 kg)

-

Certifications: CE, UL, cUL, CSA, TÜV SIL-capable

-

Manual Reference: Woodward Manual 85205

Woodward 8200-203

Core Features & Customer Value

Triple-Redundant Architecture with 2-out-of-3 Voting: The 9907-345’s three independent speed-sensing channels eliminate single points of failure in the measurement path. Unlike single-channel devices that can fail dangerously or cause spurious trips, the 2-out-of-3 voting logic requires two channels to confirm overspeed before tripping, while any two channels maintain protection if one fails. This architecture achieves the high safety availability and low spurious trip rates required for critical turbomachinery in power generation, oil and gas, and petrochemical applications. For insurance and regulatory compliance, this design supports SIL 2 and SIL 3 safety integrity levels.

De-Energize-to-Trip Fail-Safe Design: The module’s DET logic ensures that any loss of 24 VDC power, internal processor fault, or wiring failure results in immediate turbine trip. In DET systems, relays are normally energized during operation; loss of power causes spring-return contacts to open the trip circuit. This philosophy contrasts with energize-to-trip (ETT) systems where loss of power could prevent protective action. For rotating equipment where overspeed can result in rotor burst and catastrophic damage, the DET approach provides inherent safety that aligns with API 670 and ISO 10494 standards.

24 VDC Power for Modern Control Architectures: The 18-32 VDC input range accommodates standard industrial 24 VDC control power systems, battery-backed UPS installations, and distributed power architectures common in modern turbine control systems. This low-voltage DC operation simplifies power system design, reduces electrical safety hazards during maintenance, and integrates seamlessly with PLC and DCS power supplies. The wide input range (18-32 VDC) ensures continued operation during battery discharge cycles or power supply voltage transients.

Hot Replacement Capability for Reduced Downtime: The 9907-345 design allows replacement of internal subsystems (speed-sensing units, relay modules) without tripping the prime mover, provided the main power is disconnected first. This maintainability feature enables preventive maintenance or fault repair during scheduled outages without requiring complete system shutdown. For facilities with limited spare turbines or continuous-process requirements, this capability translates to significant availability improvements compared to older protection systems requiring total replacement for minor faults.

Individual Channel Diagnostics with LED Indication: Each of the three speed-sensing units features dedicated CPU status LEDs, providing immediate visual indication of channel health without requiring diagnostic software or multimeter measurements. During commissioning, these LEDs confirm proper MPU signal acquisition; during operation, they alert operators to channel degradation before protection is compromised. This diagnostic granularity reduces mean-time-to-repair (MTTR) and supports condition-based maintenance strategies.

Comprehensive Event Recording for Forensic Analysis: The 100-event recorder captures pre-trip and post-trip speed data with millisecond timestamps, enabling detailed analysis of overspeed incidents, spurious trips, or near-miss events. This forensic capability supports root-cause analysis, insurance investigations, and regulatory reporting requirements. The recorder operates independently of protection functions, ensuring data preservation even during controller faults.

Typical Applications

Gas Turbine Overspeed Protection: In power generation, mechanical drive, and oil and gas applications, the 9907-345 protects gas turbines from overspeed following generator breaker opening, compressor surge, or load coupling failure. The 24 VDC power input integrates with modern turbine control system architectures, while the fast response time (<40 ms) protects aeroderivative turbines with rapid acceleration characteristics. The triple-redundant MPU configuration handles the high reliability requirements of continuous-process plants where spurious trips cost millions in lost production.

Steam Turbine Emergency Protection: Power plant steam turbines—both utility-scale and industrial cogeneration units—utilize the 9907-345 as primary or backup overspeed protection. The 250 Hz minimum frequency accommodates large, slow-speed turbines (1800/1500 RPM), while the 25 kHz maximum covers high-speed applications. The hot replacement capability is particularly valuable in steam plants where turbine outages require extensive cooldown periods, making maintenance windows costly and infrequent.

Diesel Engine Overspeed Protection: Reciprocating engines in power generation, marine propulsion, and emergency standby applications employ the 9907-345 to prevent runaway conditions caused by fuel system failures or governor malfunctions. The 24 VDC operation matches standard engine control system voltages, simplifying integration. The 2-out-of-3 voting prevents nuisance trips from single MPU sensor noise common in diesel engine environments with high vibration levels.

Compressor and Expander Protection: Centrifugal and axial compressors in natural gas transmission, petrochemical processing, and air separation plants utilize the 9907-345 to prevent overspeed during load rejection or anti-surge valve failure. The module’s analog speed output (4-20 mA) feeds plant DCS systems for operational monitoring while the independent trip relays provide safety-function isolation from process control systems.

Emergency and Standby Power Systems: Critical facilities including hospitals, data centers, and nuclear power plants employ the 9907-345 for emergency diesel generator (EDG) overspeed protection. The SIL-capable design supports nuclear safety system requirements, while the 24 VDC operation integrates with standard station battery systems. The key-lock security prevents unauthorized modification of safety settings in regulated environments.