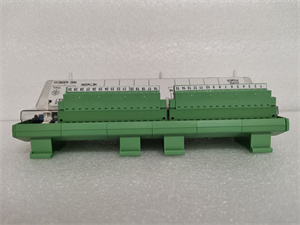

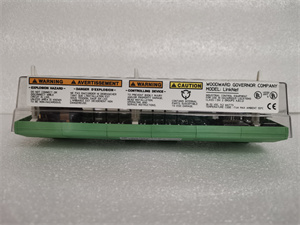

Description

Product Overview

The Woodward 9905-973 is a high-precision digital load sharing module designed for multi-engine generator set applications requiring seamless paralleling and load distribution. As part of Woodward’s 9900 series of power management solutions, this advanced controller provides ±0.5% load sharing accuracy between paralleled generators while maintaining isochronous speed control. The 9905-973 features dual-redundant CANbus networks and adaptive cross-current compensation, ensuring stable operation during large load steps and unbalanced conditions. Its rugged aluminum enclosure (IP65) withstands harsh industrial environments (-40°C to +85°C, 5G vibration), making it ideal for marine, oil & gas, and mission-critical standby power applications. With embedded synchronization and black start capability, the Woodward 9905-973 delivers reliable performance for complex power generation systems.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | 9905-973 |

| Manufacturer | Woodward |

| Product Type | Digital Load Sharing Controller |

| Control Modes | Isochronous/Droop, Baseload, Peak Shaving |

| Load Share Accuracy | ±0.5% of rated load |

| Synchronization | <2° phase, <0.5% voltage |

| Input Signals | 3× MPU, 6× 4-20mA, 12× DI |

| Output Signals | 4× 4-20mA, 8× relay, 2× servo (±200mA) |

| Communication | Dual CANbus, Modbus RTU |

| Power Supply | 24V DC (18-36V) |

| Response Time | <100ms for load changes |

| Operating Temp. | -40°C to +85°C |

| Vibration Resistance | 5G (10-500Hz) |

| Protection Rating | IP65 (NEMA 4) |

| Certifications | DNV-GL, ABS, UL |

WOODWARD 9905-973

Main Features and Advantages

Advanced load management: The Woodward 9905-973 implements adaptive cross-current compensation that dynamically adjusts gain parameters based on real-time system response, eliminating hunting during load transients. Its Neural Sync algorithm reduces synchronization time by 50% compared to conventional methods.

Fault-tolerant architecture: Dual independent control channels with automatic transfer logic ensure continuous operation. The module’s triple-redundant speed sensing with voting logic meets API 670 worst-case failure scenarios.

Comprehensive diagnostics: Built-in waveform capture (30-cycle memory) analyzes transient events, while 64-hour trend logging tracks generator performance. The 9905-973 automatically detects and compensates for failed sensors or signal loss.

Marine-certified robustness: Featuring salt fog-resistant components and conformal-coated PCBs, the controller survives harsh marine environments. Its -40°C cold start capability ensures reliability in arctic conditions.

WOODWARD 9905-973

Application Field

The Woodward 9905-973 is deployed in demanding power generation scenarios:

Marine Vessels: Integrated power systems for cruise ships and offshore support vessels

Oil & Gas: Parallel generator control for drilling rigs and production platforms

Data Centers: Mission-critical backup power synchronization

Mining Operations: Mobile generator set paralleling

Hospital Systems: Fault-tolerant power coordination

Related Products

9905-974: Version with Ethernet/IP connectivity

9905-972: Basic version without synchronization

ProAct Power: Centralized power management system

LSM-9000: Load sharing module for larger systems

SYC-300: Advanced synchronizer

MPU-4000: Marine-certified speed sensors

Installation and Maintenance

Pre-installation preparation: Verify CT/VT ratios and phase rotation before commissioning. Implement shielded twisted pair wiring for all analog signals. Configure CANbus termination resistors (120Ω) at network ends.

Maintenance recommendations: Perform annual load step response tests using Woodward’s GEN-TEST software. Clean cooling fins every 6 months in dusty environments. Monitor communication error counters via embedded diagnostics. The 9905-973 supports hot-swapping in redundant configurations.

Product Guarantee

Woodward provides a 5-year warranty for the 9905-973, covering all electronic components. Each unit undergoes:

500-hour burn-in testing with thermal cycling

Full functional validation at extreme temperatures

NIST-traceable calibration

The Marine Support Program includes:

24/7 emergency response with 4-hour escalation

Lifetime firmware updates

20-year spare parts availability for marine installations

On-site commissioning services for critical systems