Description

Key Technical Specifications

-

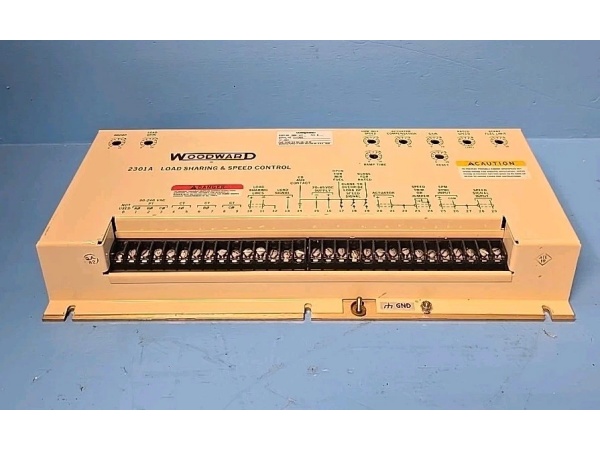

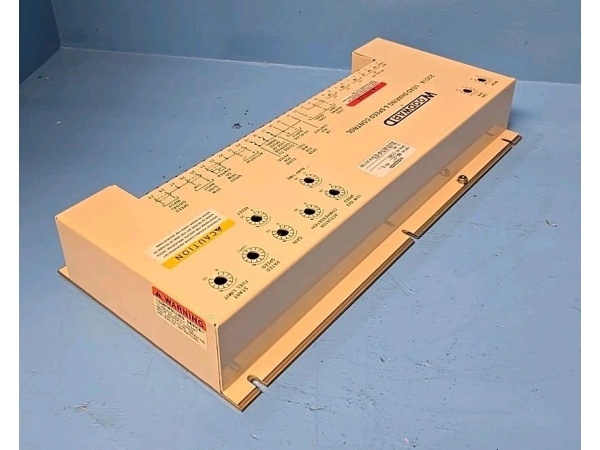

Model Number: 9905-373

-

Manufacturer: Woodward Inc.

-

Product Family: DSLC (Digital Synchronizer and Load Control)

-

Power Supply: 115 VAC or 230 VAC (switch-selectable), 50/60 Hz

-

Power Consumption: 10 VA maximum (typical for DSLC series)

-

Synchronization Method: Digital phase-locked loop with microprocessor control

-

Phase Angle Matching: ±5° to ±20° (adjustable via front panel or software)

-

Voltage Matching: Within 1% to 5% of bus voltage (programmable)

-

Frequency Matching: Biases offline generator speed to match bus frequency

-

Output Options:

-

Speed bias output to governor (raise/lower)

-

Voltage bias output to AVR (raise/lower)

-

Breaker close relay contact (dry contact, typically 5A)

-

-

Load Control Integration: Built-in load sharing and load ramp functions

-

Operating Temperature: -40°C to +70°C (-40°F to +158°F)

-

Storage Temperature: -55°C to +85°C (-67°F to +185°F)

-

Relative Humidity: 5% to 95% non-condensing

-

Mounting: Panel-mounted in control cabinet

-

Dimensions: Approximately 200 mm × 120 mm × 50 mm (typical DSLC form factor)

-

Weight: 0.6 kg (1.3 lb)

-

Front Panel Interface: LED indicators for sync status, alarms, and mode selection

-

Compatibility: 2301A, 2301E, EPG, and other Woodward governor systems

WOODWARD 9905-377

Field Application & Problem Solved

In the field, the biggest challenge with paralleling generators is the precision required for safe breaker closure. A 10-degree phase difference at 480V can produce inrush currents of 8-10 times rated, snapping shafts, stripping gears, or welding breaker contacts. The analog synchronizers like the SPM-A got you close, but the 9905-373 DSLC gets you dead-on every time using digital signal processing rather than analog comparators. It eliminates the “human factor” and the drift inherent in analog circuits.

You will typically find this module in power plants running multiple diesel or gas generator sets in island mode—mining operations, remote construction camps, marine switchboards, or industrial facilities with critical backup power. It’s designed to work with Woodward’s 2301A/2301E load sharing controls, EPG governors, or newer digital systems. The 9905-373 represents the transition from analog to digital in Woodward’s lineup, offering tighter synchronization tolerances and more flexible configuration than its SPM-A predecessors.

Its core value is preventing the catastrophic damage that comes from out-of-phase paralleling while providing integrated load control functions that analog units couldn’t match. The digital architecture allows for precise phase angle calculation, adaptive bias signals that respond to governor dynamics, and programmable slip frequency detection. Unlike the SPM-A which used analog synchroscope meters, the DSLC uses LED indicators and digital status outputs that interface with modern SCADA systems. The integrated load control means you don’t need a separate AGLC module for soft loading—the DSLC can manage the ramp rates and load sharing directly through digital communication with the governor.

Installation & Maintenance Pitfalls (Expert Tips)

Digital Outputs Require Proper Grounding

The most common field mistake with the DSLC is treating it like an analog synchronizer. The digital outputs (especially if this unit has serial communication capabilities) are sensitive to ground loops and EMI. Use shielded twisted pair for all bias signal wiring, grounding the shield at the control end only. I’ve seen installations where unshielded wiring running parallel to 480V feeder cables induced enough noise to cause erratic governor behavior—engines surging 50 RPM for no apparent reason. The shield drain wire should terminate at the designated ground lug on the chassis, never at both ends.

Phase Rotation Verification is Non-Negotiable

The DSLC is unforgiving about phase rotation. If your generator PTs are not phased identically to the bus PTs—same rotation, same polarity—the module will see a constant phase error and either refuse to synchronize or close the breaker at the wrong instant. This is especially critical when retrofitting from an SPM-A, which was more tolerant of minor phasing errors. Always verify phase rotation with a phase angle meter during commissioning. Mark the PT secondary leads clearly; I’ve seen maintenance crews swap bus and generator PT leads during routine work, resulting in immediate breaker damage on the next start attempt.

Governor Response Time Must Match DSLC Settings

The DSLC calculates bias signals based on assumed governor response characteristics. If your governor is sluggish (old hydraulic actuator) but the DSLC is set for fast response EPG dynamics, you’ll see the synchroscope “hunt”—the needle oscillates back and forth without settling. Conversely, a fast governor with slow DSLC settings causes overshoot. Check the “Governor Type” switches or software settings before commissioning. For 2301A systems, use the “Analog Governor” setting; for EPG or digital governors, use the appropriate fast-response setting.

Breaker Close Contact Timing is Critical

The DSLC’s breaker close relay has a specific pull-in time, and your breaker has a specific closing time. If the DSLC closes the contact when the vectors are aligned, but the breaker takes 8 cycles to actually close, you’ll be 8 cycles out of phase by the time the contacts meet. The DSLC has a “Breaker Close Anticipation” adjustment—use it. You need to set the anticipation time equal to your breaker’s mechanical closing time plus the relay delay. I’ve seen technicians skip this step, then wonder why they get a “thump” every time the breaker closes despite the synchroscope showing perfect alignment.

Load Sharing Line Terminations Are Still Analog

Even though the DSLC is digital internally, the load sharing interface with other Woodward controls is still analog 0-6 Vdc. The same rules apply as with the 2301A: twisted pair, shield grounded at one end only, and no ground loops. If you’re mixing DSLC-equipped units with older 2301A controls in the same plant, verify that the load sharing line impedance matches. The DSLC may have different output impedance than the analog controls, causing load sharing instability.

WOODWARD 9905-377

Technical Deep Dive & Overview

The Woodward 9905-373 is a microprocessor-based digital synchronizer and load control from the DSLC series, representing Woodward’s transition from analog to digital paralleling technology. It combines the functions of synchronization, load sharing, and soft loading into a single digital platform, eliminating the need for separate SPM-A synchronizers and AGLC loading controls in many applications.

The module operates by sampling the voltage waveforms from both the bus and generator potential transformers at high speed (typically thousands of samples per second), then using digital signal processing algorithms to calculate phase angle, frequency difference, and voltage magnitude in real-time. Unlike analog synchronizers that used discriminator circuits and analog meters, the DSLC uses a digital phase-locked loop to track the relative position of the generator voltage vector to the bus vector.

The microprocessor generates precise bias signals for both speed (frequency) and voltage matching. These are typically 0-5 Vdc or 4-20 mA signals sent to the governor and AVR respectively. The digital architecture allows for programmable “dead bus” closing—automatically energizing a dead bus from the first available generator—and “live bus” synchronization with adjustable phase angle windows. The breaker close output is a relay contact that energizes when all parameters fall within set limits, with programmable anticipation timing to compensate for breaker mechanical delay.

From a system architecture perspective, the 9905-373 functions as the “brain” of the paralleling system. It receives status from the generator control switchgear (breaker auxiliary contacts, mode selection), processes synchronization logic, and outputs control signals to the governor and AVR. The load control functions allow it to manage soft loading ramps, base loading against utility, and import/export control through digital integration with the plant control system.

The DSLC series typically includes serial communication capabilities (Modbus or similar) that allow remote monitoring of synchronization status, alarm conditions, and parameter adjustment. This distinguishes it from the older SPM-A series which was purely hardwired. However, the fundamental reliability principle remains—the 9905-373 is designed for continuous duty in generator control cabinets, with convection cooling and no moving parts.

The 9905-373 specifically is an earlier revision (Rev. T noted in some listings) of the DSLC platform, predating the 9905-795/797/708 variants that offered enhanced features. It represents the first generation of Woodward’s digital synchronizer technology, bridging the gap between the analog SPM-A series and the fully integrated EasyGen digital control platforms that followed.