Description

9905-005: Product Overview

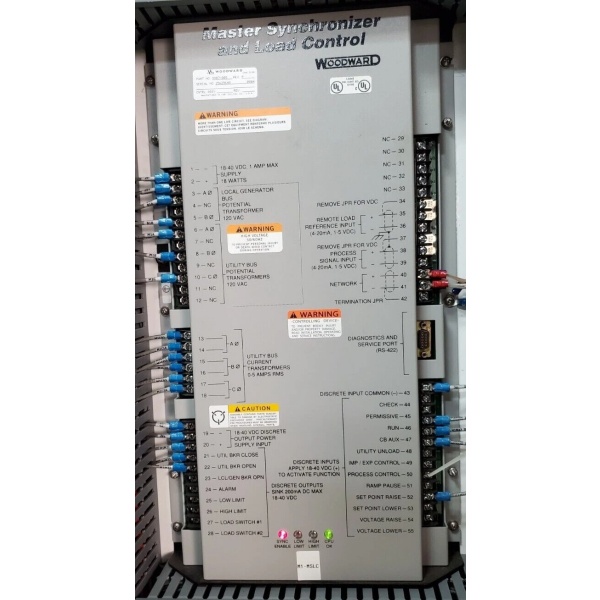

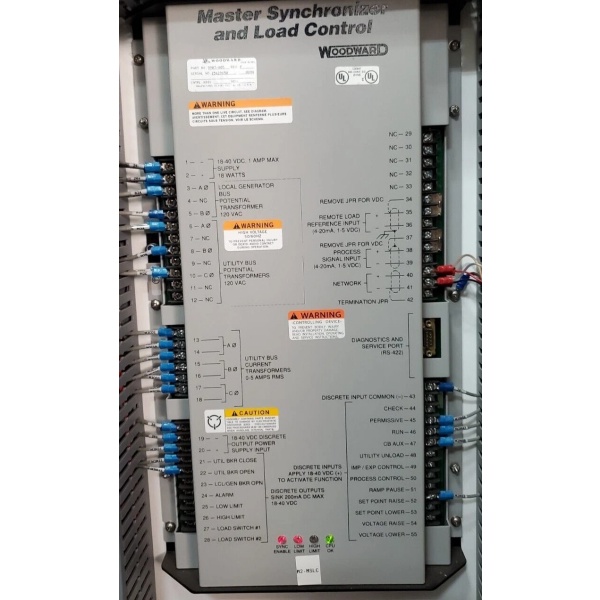

The 9905-005 functions as an automatic synchronizing device within Woodward’s SPM-A (Synchronizing and Paralleling Module – Automatic) series, specifically engineered for safe and precise paralleling of AC generators to utility grids or common bus systems. In the generator control system architecture, this unit occupies the critical synchronization layer—ensuring that voltage, frequency, and phase angle parameters match between the incoming generator and the running bus before permitting breaker closure.

Positioned typically in generator control panels, switchgear enclosures, or turbine control systems, the 9905-005 operates as a standalone synchronization module requiring only potential transformer (PT) voltage inputs and control power to implement complete automatic synchronizing functionality. Its analog and digital circuitry continuously monitors the voltage and phase relationship between the generator and bus, calculating slip frequency and phase angle advance to predict the optimal breaker closure moment.

The module’s primary role is to eliminate the hazardous conditions associated with manual paralleling or out-of-phase closure. When generator and bus voltages differ significantly, closing the breaker creates destructive electromagnetic torque and current inrush that can damage generator windings, couplings, and driven equipment. The 9905-005 prevents such damage by enforcing strict synchronizing criteria: voltage magnitude match (typically ±5%), frequency match (slip within ±0.5 Hz), and phase angle alignment (within ±10 electrical degrees) at the instant of breaker contact closure.

As part of the SPM-A series, the 9905-005 benefits from Woodward’s extensive experience in generator control and protection. The series includes variants for different applications—9905-001, 9905-002, 9905-003, and 9905-005—each optimized for specific voltage levels, frequency ranges, or control schemes. The 9905-005 specifically supports both 50 Hz and 60 Hz applications, making it suitable for global deployment in power generation, marine, and industrial cogeneration facilities.

WOODWARD 9905-005

9905-005: Technical Specifications

-

Model Number: 9905-005

-

Manufacturer: Woodward Inc.

-

Product Type: SPM-A Automatic Synchronizer

-

System Family: Woodward SPM-A Synchronizer Series

-

Function: Automatic generator synchronization and paralleling control

-

Frequency Range: 50/60 Hz (auto-sensing or configurable)

-

Voltage Input: Generator and bus PT (potential transformer) inputs, typically 120 VAC nominal

-

Voltage Matching Range: ±10% of nominal (adjustable)

-

Voltage Matching Accuracy: ±2% typical

-

Slip Frequency Range: ±0.5 Hz (adjustable)

-

Phase Angle Window: ±10 electrical degrees (adjustable)

-

Breaker Closure Advance Angle: Automatically calculated based on slip frequency and breaker operating time

-

Synchronizing Check: Voltage magnitude, phase angle, and slip frequency supervision

-

Relay Outputs: Form C (SPDT) contacts for breaker close command and status indication

-

Relay Contact Rating: 5 A @ 250 VAC/30 VDC resistive

-

Dead Bus Closure: Enabled/disabled via configuration

-

Paralleling Modes: Automatic synchronization, manual permissive, dead bus closure

-

Timing: Adjustable breaker closure advance angle compensation (0-500 ms typical)

-

Status Indication: LED indicators for sync-in-progress, voltage OK, frequency OK, phase OK, breaker close

-

Input Power: 120 VAC or 24 VDC (variant dependent)

-

Power Consumption: <10 W typical

-

Operating Temperature: -20°C to +60°C (-4°F to +140°F)

-

Storage Temperature: -40°C to +85°C (-40°F to +185°F)

-

Relative Humidity: 5% to 95%, non-condensing

-

Mounting: Panel mount or DIN rail mount (adapter dependent)

-

Dimensions: Approximately 6″ × 4″ × 2″ (152 × 102 × 51 mm) typical SPM-A form factor

-

Weight: <1 kg (<2.2 lbs)

-

Certifications: CE, UL, cUL (typical for Woodward generator control products)

-

Manual Reference: Woodward SPM-A Installation and Operation Manual

Core Features & Customer Value

Automatic Voltage and Phase Matching: The 9905-005 eliminates the manual adjustment required for generator paralleling by automatically monitoring both generator and bus voltages and indicating when magnitude and phase align. For plant operators, this reduces the skill level required for generator synchronization and eliminates the risk of human error during stressful startup situations. The automatic matching ensures consistent, repeatable paralleling that protects generator windings and mechanical couplings from the torque shock of out-of-phase closure.

Slip Frequency Control with Predictive Closure: Rather than simply waiting for phase coincidence, the module calculates slip frequency (the rate of phase angle change between generator and bus) and predicts the breaker closure moment. It issues the breaker close command in advance of phase alignment by an amount equal to the breaker’s mechanical operating time, ensuring that contacts actually close at zero phase angle. This predictive algorithm allows successful synchronization even with significant frequency differences (up to ±0.5 Hz), reducing the time required to match generator speed to the grid.

Dead Bus Closure Capability: The 9905-005 includes logic for dead bus closure—automatically closing the generator breaker onto a de-energized bus without requiring synchronization checks. This feature proves essential for black-start operations, islanded microgrids, or emergency power systems where the generator must energize the bus before other sources parallel. The dead bus function includes voltage verification to prevent closure onto an energized bus, maintaining safety while providing operational flexibility.

Permissive and Automatic Operating Modes: The module supports both fully automatic synchronization (initiating breaker closure without operator action once parameters align) and permissive modes (indicating sync readiness but requiring operator or external control system to execute closure). This flexibility allows integration into manual control schemes for critical generators or fully automatic schemes for unmanned facilities or automatic transfer sequences.

Robust Relay Outputs for Breaker Control: The Form C relay contacts provide both normally-open (close command) and normally-closed (status/alarm) configurations, interfacing directly with generator breaker shunt trip and close circuits. The 5-ampere contact rating accommodates most medium-voltage breaker control schemes without interposing relays, simplifying panel wiring and reducing failure points. Contact status feedback allows the synchronizer to verify successful breaker operation and annunciate failures.

WOODWARD 9905-005

Typical Applications

Emergency Generator Paralleling: In facilities with multiple emergency generators (hospitals, data centers, critical manufacturing), the 9905-005 provides automatic synchronization when generators start in response to utility outages. The dead bus closure function allows the first generator to energize the emergency bus, while subsequent generators automatically parallel to share load. This automatic paralleling eliminates manual synchronization during stressful outage conditions when operator attention is focused on other critical tasks.

Cogeneration and Distributed Generation: Industrial cogeneration plants utilizing gas turbines, reciprocating engines, or steam turbines for on-site power generation employ the 9905-005 to synchronize generators to the utility grid for import/export control or islanded operation. The precise synchronization allows seamless transfer between grid-connected and islanded modes without process disruptions, enabling peak shaving and demand response strategies that require frequent generator paralleling.

Marine and Offshore Power Systems: Shipboard electrical plants and offshore platform power generation utilize the 9905-005 for generator paralleling in floating or isolated systems. The module’s 50/60 Hz capability accommodates both European and North American vessel electrical standards. The robust design withstands vibration, humidity, and temperature variations common in marine engine rooms without requiring climate-controlled enclosures.

Automatic Transfer and Peak Shaving Systems: Utilities and large industrial customers employ the 9905-005 in automatic transfer schemes where on-site generation parallels with the grid during peak demand periods or utility curtailment events. The automatic synchronization allows unattended operation, with the module initiating paralleling based on remote dispatch signals or local power demand algorithms. Precise synchronization prevents power quality disturbances that could affect sensitive electronic equipment.

Renewable Energy Integration: Hybrid power systems combining diesel generators with solar PV, wind, or battery storage use the 9905-005 to synchronize backup generators when renewable output is insufficient. The fast synchronization (typically <2 minutes from start command to paralleled operation) minimizes battery discharge and ensures continuous power for critical loads during renewable resource fluctuations.